1.产 品 资 料 介 绍:

620-0054作为工业级高性能系统控制模块,具备多设备统筹联动、精准指令下发、强抗干扰及灵活扩展能力,可作为核心控制单元衔接感知、执行与上位系统,实现全链路自动化管控,具体应用领域如下:

1. 智能工厂产线:统筹机器人、输送设备与检测终端联动,精准下发启停、调速指令,实现产线自动化闭环管控。

2. 石油化工装置:作为装置核心控制单元,联动阀门、泵体与传感器,精准调控反应压力、流量,保障工艺合规。

3. 电力系统调度:适配变电站自动化系统,统筹高低压设备运行,实现负荷动态分配与故障应急调控。

4. 轨道交通信号系统:管控列车运行间隔、进站停靠指令,联动安防与供电系统,保障行车安全有序。

5. 水处理成套设备:统筹过滤、消毒、供水全流程设备,根据水质参数自动调整运行模式,适配变负荷工况。

6. 包装自动化生产线:联动灌装、封口、贴标设备,精准同步运行节奏,优化包装效率与成品合格率。

7. 冶金连铸生产线:统筹结晶器、拉矫机等设备,根据钢水温度动态调整运行参数,保障连铸工艺稳定。

8. 仓储自动化系统:管控AGV小车、堆垛机与货架设备,实现货物出入库、分拣全流程智能调度。

9. 新能源储能系统:统筹储能单元充放电控制,联动电网调度指令,实现削峰填谷与电能稳定输出。

10. 制药无菌生产线:严格管控配料、反应、灌装设备联动,符合GMP标准,保障生产过程无菌可控。

11. 船舶动力控制系统:统筹主机、辅机与推进系统,精准调控运行参数,适配船舶航行复杂工况。

12. 玻璃制造生产线:管控熔窑、成型机与退火设备,根据温度曲线自动调整运行状态,保障玻璃品质均匀。

13. 环保脱硫脱硝系统:统筹喷淋、催化设备运行,根据烟气成分自动调整药剂投放量,达标处理尾气。

14. 半导体封装测试线:精准管控封装、检测设备联动,适配精密工艺需求,保障芯片封装质量。

15. 楼宇智能管控系统:统筹空调、照明、安防设备,根据环境参数与使用需求自动切换运行模式,优化能耗。

该模块凭借高效统筹能力、精准调控性能及强环境适配性,搭建起设备与系统的联动核心,为各行业自动化升级与智能化管控提供可靠支撑。

620-0054系统控制模块 英文资料:

As an industrial grade high-performance system control module, 620-0054 has the ability to coordinate multiple devices, issue precise instructions, resist strong interference, and flexibly expand. It can be used as a core control unit to connect perception, execution, and upper level systems, achieving full chain automation control. The specific application areas are as follows:

1. Intelligent factory production line: Coordinate the linkage between robots, conveying equipment, and detection terminals, accurately issue start stop and speed control instructions, and achieve automated closed-loop control of the production line.

2. Petrochemical plant: As the core control unit of the plant, it links valves, pump bodies, and sensors to accurately regulate reaction pressure and flow rate, ensuring process compliance.

3. Power system scheduling: Adapt to substation automation systems, coordinate the operation of high and low voltage equipment, achieve dynamic load distribution and emergency control of faults.

4. Rail transit signal system: controls train running intervals, station stop instructions, links security and power supply systems, and ensures safe and orderly train operation.

5. Complete set of water treatment equipment: It integrates the entire process of filtration, disinfection, and water supply, automatically adjusts the operating mode according to water quality parameters, and adapts to variable load conditions.

6. Packaging automation production line: linked filling, sealing, and labeling equipment, precise and synchronized operation rhythm, optimized packaging efficiency and finished product qualification rate.

7. Metallurgical continuous casting production line: Coordinate equipment such as crystallizers and straightening machines, dynamically adjust operating parameters according to the temperature of the molten steel, and ensure the stability of the continuous casting process.

8. Warehouse automation system: Control AGV carts, stackers, and shelving equipment to achieve intelligent scheduling of the entire process of goods in and out of the warehouse and sorting.

9. New energy storage system: Coordinate the charging and discharging control of energy storage units, link with grid dispatch instructions, and achieve peak shaving and valley filling as well as stable power output.

10. Pharmaceutical aseptic production line: Strictly control the linkage of ingredients, reactions, and filling equipment, comply with GMP standards, and ensure that the production process is sterile and controllable.

11. Ship power control system: coordinates the main engine, auxiliary engine, and propulsion system, accurately regulates operating parameters, and adapts to complex ship navigation conditions.

12. Glass manufacturing production line: Control the melting furnace, forming machine, and annealing equipment, automatically adjust the operating status according to the temperature curve, and ensure uniform glass quality.

13. Environmental protection desulfurization and denitrification system: Coordinate the operation of spraying and catalytic equipment, automatically adjust the dosage of chemicals according to the composition of flue gas, and treat tail gas in compliance with standards.

14. Semiconductor packaging testing line: precise control of packaging and testing equipment linkage, adapting to precision process requirements, ensuring chip packaging quality.

15. Building intelligent control system: coordinates air conditioning, lighting, and security equipment, automatically switches operating modes based on environmental parameters and usage needs, and optimizes energy consumption.

This module, with its efficient coordination capability, precise control performance, and strong environmental adaptability, establishes a core linkage between equipment and systems, providing reliable support for automation upgrades and intelligent control in various industries.

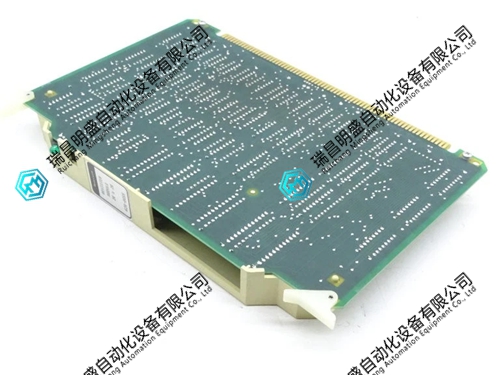

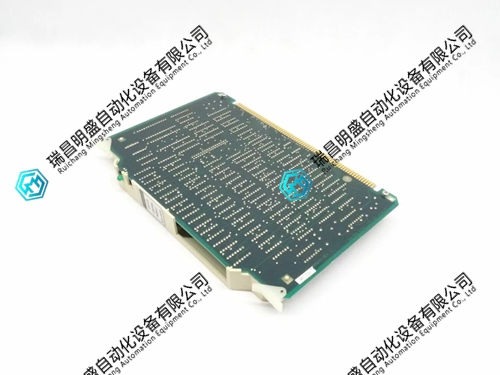

620-0054系统控制模块 产品展示

产品视频

3.其他产品

MECS UTX1700PTFE绝缘材料

MOTOROLA PMC-6130-J 0100RSDPMC-J 控制板模块

GE DS200DCFBG1BJBFCB模块

4.其他英文产品

SDCS-CON4-COAT-ROHS Programmable Processor

HONEYWELL 05704-A-0146 Digital I/O Module

SCHNEIDER 140SAI94000S Analog Safety Input Module

| 489-P5-HI-A20-E-H | SS7-35B | IC3600TPAE1B |

| 489-P5-HI-A20-E | PSR45A-275 | IC3600TPAB1B |

| 489-P5-HI-A20 | SRB-MS-ILK5 | IC3600TPAB1 |

| 489-P5-HI-A1-E | SS2000OF | IC3600TPAA1A |

| 489-P1-LO-A20-E | SS2000M-D4 | IC3600TPAA1 |

| 489-P1-LO-A20 | S6961NP | IC3600TLFC1C |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218