MOOG 77-159气门阀

1.产 品 资 料 介 绍:

- 电液驱动集成架构:Moog 77-159 气门阀采用 “力矩马达 + 液压执行” 一体化设计,核心由永磁力矩马达、双喷嘴挡板先导级与滑阀执行级组成,相比传统机械气门省去凸轮轴传动结构,可通过电信号直接控制气门开度,适配发动机可变气门正时(VVT)系统的柔性调节需求。

- 发动机工况适配设计:阀体采用紧凑型轻量化结构,重量控制在 200-300g 区间,适配发动机缸盖狭小安装空间;安装接口符合汽车行业标准化尺寸,可直接集成于柴油或汽油发动机的配气机构,降低改装适配成本。

- 抗污染密封结构:阀芯与阀套采用间隙密封配合,表面经氮化硬化处理提升耐磨性,配合可更换的进口防尘密封圈,能抵御发动机舱内油污、粉尘侵蚀,减少因杂质导致的阀芯卡滞故障。

- 宽域压力适配能力:最大工作压力可达 21MPa,适配发动机液压系统的典型压力范围,在 5-18MPa 区间内均能保持稳定的气门驱动精度,满足怠速、加速、高速等不同工况下的配气需求。

- 毫秒级动态响应:100% 阶跃响应时间≤8ms,频率响应达 50Hz 以上,力矩马达的低摩擦设计大幅降低信号滞后,可快速跟随 ECU 指令调整气门开启 / 关闭时机,保障发动机在变工况下的动力输出平顺性。

- 高精度开度控制:滞环误差低于 0.3%,气门开度分辨率达 0.1mm,通过阀芯位置机械反馈形成闭环控制,确保不同转速下气门升程与正时的精准匹配,助力发动机实现低油耗与高功率的平衡。

- 故障安全保护机制:内置机械零偏结构,当控制信号丢失或断电时,弹簧力可驱动阀芯复位至 “气门关闭” 状态,防止气门突开导致的发动机超速风险,提升动力系统运行安全性。

- ECU 精准协同适配:支持 0-5V 模拟信号或 PWM 脉冲信号输入,可直接与发动机 ECU 控制系统对接,无需额外信号转换模块,通过 ECU 的实时工况计算,实现气门参数的动态优化调节。

MOOG 77-159气门阀 英文资料:

1、 Infrastructure and Design Characteristics

Integrated architecture of electro-hydraulic drive: The Moog 77-159 valve adopts an integrated design of "torque motor+hydraulic execution", consisting of a permanent magnet torque motor, a dual nozzle baffle pilot stage, and a slide valve execution stage. Compared with traditional mechanical valves, it eliminates the camshaft transmission structure and can directly control the valve opening through electrical signals, adapting to the flexible adjustment requirements of the engine's variable valve timing (VVT) system.

Engine operating condition adaptation design: The valve body adopts a compact and lightweight structure, with a weight controlled within the range of 200-300g, suitable for the narrow installation space of the engine cylinder head; The installation interface conforms to the standardized dimensions of the automotive industry and can be directly integrated into the valve mechanism of diesel or gasoline engines, reducing the cost of modification and adaptation.

Anti pollution sealing structure: The valve core and valve sleeve adopt a gap sealing fit, and the surface is treated with nitride hardening to improve wear resistance. Combined with replaceable imported dust-proof sealing rings, it can resist oil and dust erosion in the engine compartment and reduce valve core jamming faults caused by impurities.

2、 Core performance and control accuracy

Wide range pressure adaptation capability: The maximum working pressure can reach 21MPa, and it can adapt to the typical pressure range of the engine hydraulic system. It can maintain stable valve driving accuracy within the range of 5-18MPa, meeting the valve control requirements under different working conditions such as idle, acceleration, and high speed.

Millisecond level dynamic response: 100% step response time ≤ 8ms, frequency response above 50Hz, low friction design of torque motor significantly reduces signal lag, can quickly follow ECU instructions to adjust valve opening/closing timing, ensuring smooth power output of the engine under variable operating conditions.

High precision opening control: hysteresis error is less than 0.3%, valve opening resolution reaches 0.1mm, and closed-loop control is formed through mechanical feedback of valve core position to ensure precise matching of valve lift and timing at different speeds, helping the engine achieve a balance between low fuel consumption and high power.

3、 Security and system collaboration

Fault safety protection mechanism: Built in mechanical zero bias structure. When the control signal is lost or power is cut off, the spring force can drive the valve core to reset to the "valve closed" state, preventing the risk of engine overspeed caused by sudden valve opening and improving the safety of power system operation.

ECU precise collaborative adaptation: supports 0-5V analog signal or PWM pulse signal input, can be directly connected to the engine ECU control system, without the need for additional signal conversion modules, and dynamically optimizes and adjusts valve parameters through real-time working condition calculation of the ECU.

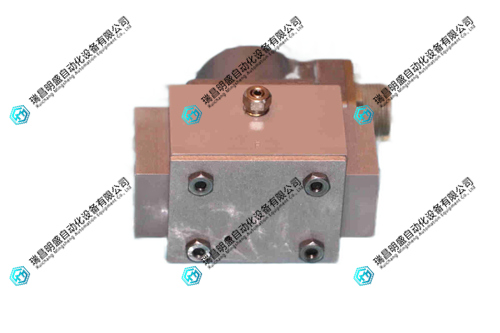

MOOG 77-159气门阀 产品展示

产品视频

3.其他产品

Alcatel Lucent 3FE66721AB VAI2AJTNAA端口板

Alcatel-Lucent 5010 89-0411-A交换机模块

Alcatel-Lucent 53LI1A3AXX控制板

4.其他英文产品

NI PXIe-5630 Vector Signal Analyzer Module

NI PXI-5122 Data Acquisition Card Module

NI PXI-4130 I/O module

| 565-5-5-A | 6SC6140-1AG00 | NASM01 |

| 5645-039 | 6SC6101-5B-Z | NCOM03 |

| 5645-027 | 6SC9112-3BA05 | INNIS01 |

| 5645-024 | 6SC6100-0AA80 | IMMFP02 |

| 5645-021 | SS7B351PDOT | INNPM01 |

| 5645 | HG93A603 | NCIS02 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218