TOYOTA ADP-513-55电路控制板模块

1.产 品 资 料 介 绍:

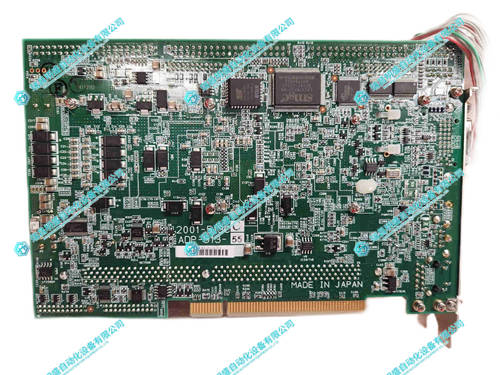

- 型号:ADP-513-55

- 类型:电路控制板模块(PCB 控制单元)

- 主要功能:具备高效的信号采集能力,能及时获取各类设备信号;拥有精准的逻辑控制功能,确保设备按既定逻辑运行;同时具备稳定的数据传输功能,保障信息在系统内的顺畅流转。

- 常见接口:配备多针插座,可满足多线路连接需求;设有排针,方便与其他部件进行快速对接;还具备通信接口端口,保障数据通信的顺畅。

- 安装方式:支持机架式安装,能稳固地固定在机架上;也可采用插槽式模块化安装,便于安装和更换,适应不同的设备安装场景。

- 适用环境:专为工业现场设计,具备出色的抗震动性能,可在设备运行产生振动的环境下稳定工作;同时耐温差性能良好,能适应工业现场不同的温度变化。

- 配套系统:与 Toyoda 数控控制系统、自动化控制平台完美适配,保障系统的整体运行效率。

- CNC 数控机床:广泛应用于 Toyoda 品牌的立式 / 卧式加工中心、磨床等数控机床,承担核心信号与控制处理工作,确保数控机床的精准运行。

- 自动化装配与加工产线:作为信号与指令分配单元,在自动化装配与加工产线中发挥重要作用,实现机械手臂、传送系统、夹具等自动化部件的协调控制,保障产线的高效运转。

- 设备维护与替换:常用于老旧机床的控制板维修、更换,无需对机床进行整体改造,就能有效延长设备的服役周期,降低设备维护成本。

- 工业设备研发与测试:在工业设备研发与测试平台中,作为模拟或实际运行控制逻辑的硬件载体,为研发和测试工作提供可靠的硬件支持,助力新设备和新技术的研发。

英文资料:

Introduction to TOYOTA ADP-513-55 Circuit Control Board Module

The TOYOTA ADP-513-55 circuit control board module is an essential core functional unit in Toyota's CNC machine tools and industrial automation equipment. Its core responsibilities include signal acquisition, logical operations, and distribution of control instructions. It is like the "nerve center" in the equipment system, serving as a key interface between the main control unit and peripheral execution components, effectively ensuring the stability and response speed of equipment operation. Its presence is often seen in Toyota's machining centers, grinders, and automated production line control systems.

Technical parameters

Model: ADP-513-55

Type: Circuit Control Board Module (PCB Control Unit)

Main function: It has efficient signal acquisition capability and can timely obtain signals from various devices; Having precise logic control function to ensure that the equipment operates according to established logic; Simultaneously possessing stable data transmission capabilities to ensure smooth flow of information within the system.

Common interfaces: equipped with multi pin sockets to meet the needs of multiple line connections; Equipped with needle arrangement for quick integration with other components; It also has communication interface ports to ensure smooth data communication.

Installation method: Supports rack mounted installation and can be firmly fixed on the rack; Slot type modular installation can also be used for easy installation and replacement, adapting to different device installation scenarios.

Applicable environment: Designed specifically for industrial sites, it has excellent anti vibration performance and can work stably in environments where equipment generates vibration during operation; At the same time, it has good temperature resistance and can adapt to different temperature changes in industrial sites.

Supporting system: Perfectly compatible with Toyota CNC control system and automation control platform, ensuring the overall operational efficiency of the system.

Application scenarios

CNC machine tools: widely used in Toyota's vertical/horizontal machining centers, grinders and other CNC machine tools, responsible for core signal and control processing work, ensuring the precise operation of CNC machine tools.

Automated assembly and processing production line: As a signal and instruction distribution unit, it plays an important role in automated assembly and processing production lines, achieving coordinated control of automation components such as robotic arms, conveyor systems, fixtures, etc., and ensuring efficient operation of the production line.

Equipment maintenance and replacement: commonly used for repairing and replacing control boards of old machine tools, without the need for overall modification of the machine tool, it can effectively extend the service life of the equipment and reduce maintenance costs.

Industrial equipment research and testing: In the industrial equipment research and testing platform, as a hardware carrier for simulating or actually running control logic, it provides reliable hardware support for research and testing work, and assists in the development of new equipment and technologies.

2.产 品 展 示

3.其他产品

4.其他英文产品

RADISYS 061-01450-0010 Network Adapter

Teknic SST-1500-XCX Digital Servo Drive

| 6ES5374-0AA11 | 6SC6110-0GB00 | 6ES5312-5AA31 |

| 6ES5373-1AA41 | CACR-SR10BB1AM | 6DD2920-0XC02 |

| 6ES5372-1AA61 | 6SC9121-5CD15 | 6ES308-3UC11 |

| 6ES5370-0AA41 | CACR-DR15BA13SY26 | 6AV35201EL00 |

| 6ES5340-3KB21 | 6SC6111-1VA00 | 6DD2920-0XC00 |

| 6ES5330-8MA11 | 6SC6170-0FC00 | 6ES5266-8MA11 |

Contact: +86 15270269218