TOYOTA TP-7217-4界面卡

1.产 品 资 料 介 绍:

- 型号:TP-7217-4

- 类型:界面卡(HMI 接口模块),是实现人机交互的关键硬件组件。

- 功能:具备数据交互功能,确保操作员与系统之间信息的准确传递;能够进行信号转换,将不同类型的信号进行适配处理;可实现状态显示,让操作员实时了解设备的运行情况。

- 接口:配备多种工业通信接口,能够与数控系统总线完美兼容,保障了数据传输的稳定性和兼容性。

- 安装方式:采用插槽式模块化安装,这种安装方式不仅便于快速安装,还能在需要维护或更换时提高效率,适应工业设备的安装和维护需求。

- 适用环境:针对工业自动化现场的环境特点设计,具备耐振动性能,可在设备运行产生振动的情况下保持稳定工作;同时采用耐温差设计,能适应工业现场温度的波动变化。

- 数控机床操作界面:在数控机床操作界面中,连接操作面板和主控制器,操作员通过它可以进行参数设置,精准调整机床的各项运行参数;实现状态监控,实时掌握机床的工作状态;还能进行操作指令输入,控制机床的运行流程。

- 自动化生产线监控:用于自动化生产线监控时,能够采集生产线的各类状态信息,如设备运行速度、产品合格率等,并及时向上位机或控制中心反馈这些关键数据,为生产调度和决策提供依据。

- 设备状态显示与报警:通过指示灯、显示器等输出设备,实时展示设备的运行状态,如正常运行、待机、故障等。当设备出现故障时,能及时发出故障报警信息,提醒工作人员进行处理,减少故障对生产的影响。

- 系统集成与升级:作为老旧系统的界面升级模块,可有效提高人机交互体验,让操作员的操作更加便捷舒适;同时提升系统的控制精度,使设备的运行更加精准可靠,延长老旧系统的使用寿命。

英文资料:

Introduction to TOYOTA TP-7217-4 Interface Card

TOYOTA TP-7217-4 Interface Card is a human-machine interface (HMI) module designed specifically for Toyota CNC machine tools and automation systems, providing an efficient communication bridge between operators and machine control systems. It undertakes important responsibilities such as signal conversion, data transmission, and interface display input and output. Through the collaborative operation of these functions, it effectively improves the operational convenience of the equipment and accelerates the response efficiency of the system, making human-machine interaction in industrial production smoother and more efficient.

Technical parameters

Model: TP-7217-4

Type: Interface card (HMI interface module), which is a key hardware component for implementing human-computer interaction.

Function: Equipped with data exchange function to ensure accurate transmission of information between operators and the system; Capable of signal conversion and adapting different types of signals for processing; It can achieve status display, allowing operators to understand the real-time operation status of the equipment.

Interface: Equipped with multiple industrial communication interfaces, it can be perfectly compatible with the CNC system bus, ensuring the stability and compatibility of data transmission.

Installation method: Adopting slot type modular installation, this installation method not only facilitates quick installation, but also improves efficiency when maintenance or replacement is needed, adapting to the installation and maintenance needs of industrial equipment.

Applicable environment: Designed for the environmental characteristics of industrial automation sites, it has vibration resistance and can maintain stable operation even when equipment generates vibration during operation; Simultaneously adopting a temperature resistant design, it can adapt to fluctuations in temperature in industrial sites.

Application scenarios

Numerical control machine operation interface: In the numerical control machine operation interface, connect the operation panel and the main controller, and the operator can set parameters and accurately adjust various operating parameters of the machine through it; Realize status monitoring and real-time grasp of the working status of the machine tool; It can also input operation instructions and control the operation process of the machine tool.

Automated production line monitoring: Used for monitoring automated production lines, it can collect various status information of the production line, such as equipment operating speed, product qualification rate, etc., and timely feedback these key data to the upper computer or control center, providing a basis for production scheduling and decision-making.

Equipment status display and alarm: Real time display of the device's operating status, such as normal operation, standby, fault, etc., through output devices such as indicator lights and displays. When the equipment malfunctions, it can promptly issue a fault alarm message to remind the staff to handle it and reduce the impact of the malfunction on production.

System integration and upgrade: As an interface upgrade module for old systems, it can effectively improve the human-computer interaction experience and make the operator's operation more convenient and comfortable; Simultaneously improving the control accuracy of the system, making the operation of the equipment more precise and reliable, and extending the service life of old systems.

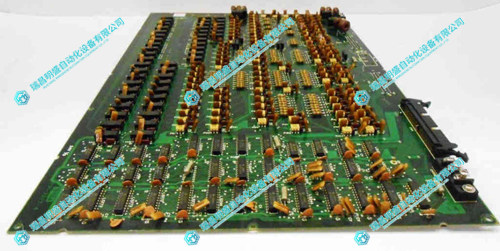

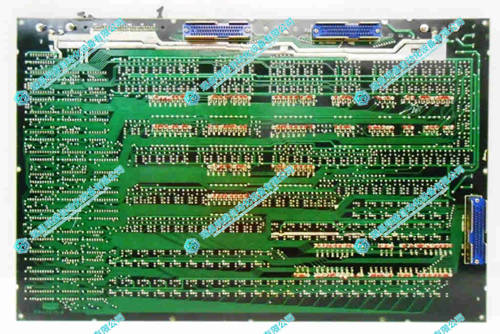

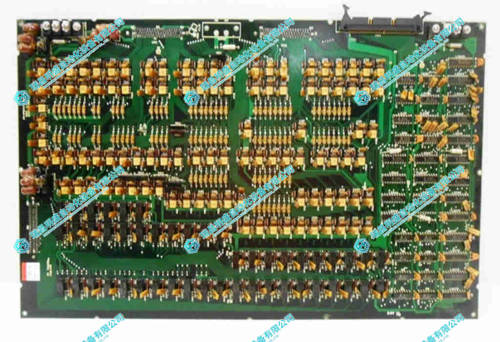

2.产 品 展 示

3.其他产品

4.其他英文产品

ABB SB822 3BSE018172R1 rechargeable

ABB UN0803B-P Printed Circuit Board

| 6ES5261-4UA11 | 6SC9731-0GL0 | TOSHIBA UTNH23A |

| 6ES5256-3AA11 | CACR-SR20BE12M | TOSHIBA USIO21 |

| 6ES5252-5BB11 | 6SC6110-5DA00 | TRICONEX 3806 |

| 6ES5252-4DA11 | CACR-SR03AB1ER-V | TOSHIBA HFAS11**S |

| 6ES5252-4BA11-2EA1 | 6SC9811-4BC10 | TOSHIBA UTLH21 |

| 6ES5247-5AA31 | CACR-SR44BB1AMY114 | TRICONEX 3806E |

Contact: +86 15270269218