TOYOTA TD-1879-4通信模块

1.产 品 资 料 介 绍:

- 通信方式:支持 RS-232、RS-485、CAN、工业以太网等常见方式,也可适配丰田专用总线协议,兼容性强。

- 数据传输速率:最高可达数 Mbps(视所选协议而定),能满足高速数据传输需求。

- 信号隔离:采用光耦隔离或变压器隔离方式,有效增强抗干扰能力,保障通信稳定。

- 接口形式:提供工业端子排、RJ45、D-sub 接口等(依设计不同),方便与各类设备连接。

- 工作电压:DC 5V / 12V / 24V(视型号而定),可适应不同的供电环境。

- 工作环境:能在 - 10℃~+55℃温度范围内工作,具备抗震、防尘、防电磁干扰设计,适应复杂工业场景。

- 安装方式:有机架式和模块化插拔式两种,便于安装和维护。

英文资料:

The TOYOTA TD-1879-4 communication module is a key industrial communication interface unit in Toyota's automated production system. Its main function is to exchange data and transmit signals between the main control system and various peripheral devices. It supports high-speed and stable data communication, enabling real-time collaboration among multiple devices, and is an indispensable part of production line control, robot system integration, and detection data transmission.

1、 Technical parameters (example, specific subject to actual model information)

Communication method: Supports common methods such as RS-232, RS-485, CAN, industrial Ethernet, and can also adapt to Toyota's dedicated bus protocol, with strong compatibility.

Data transmission rate: up to several Mbps (depending on the selected protocol), capable of meeting high-speed data transmission requirements.

Signal isolation: using optocoupler isolation or transformer isolation methods to effectively enhance anti-interference ability and ensure communication stability.

Interface form: Provide industrial terminal blocks, RJ45, D-sub interfaces, etc. (depending on the design) for easy connection with various devices.

Working voltage: DC 5V/12V/24V (depending on the model), can adapt to different power supply environments.

Working environment: capable of working within a temperature range of -10 ℃ to+55 ℃, with seismic, dustproof, and electromagnetic interference resistant designs, suitable for complex industrial scenarios.

Installation methods: organic rack and modular plug-in, easy to install and maintain.

2、 Application scenarios

(1) Automated production line data exchange

Used for real-time data transmission and synchronous control between production workstations, achieving precise communication linkage in multi machine collaborative processes, ensuring coordinated operation of various links in the production line, and improving production efficiency.

(2) Industrial Robot System

Transmit motion control instructions between the robot and the control cabinet, and accurately feedback the robot's status to the main control system to ensure that the robot operates accurately according to the instructions.

(3) Detection and monitoring system

Transfer the quality data collected by the testing equipment to the central controller, support online quality traceability and statistical analysis, and assist enterprises in controlling product quality.

(4) Remote monitoring and maintenance of equipment

Support communication with upper computers, SCADA systems, or remote servers to achieve remote diagnosis and parameter updates of equipment status, reduce maintenance costs, and minimize downtime.

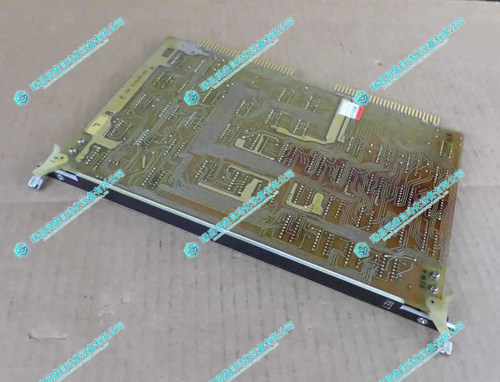

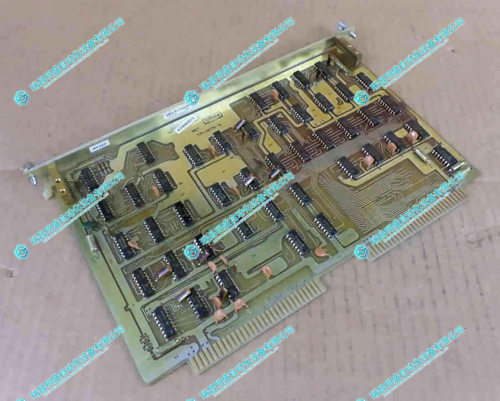

2.产 品 展 示

3.其他产品

INDRAMAT TDM1.3-050-300-W1-000 驱动模块

4.其他英文产品

KOLLMORGEN CP310250 PRD-P310250Z-55 serv

| UR8LH | CACR-IR20SEB | ATCA-FM40 |

| UR8HH | CACR-SR05SZ1SSY85 | 115970-010 |

| UR8GH | CACR-SR20BE12G-E, | 44063909 |

| UR8FV | CACR-CSL20DL16AAA, | EPC-8A |

| UR8FH | CACR-SR10BZ1SF | 60-0504-03 |

| UR8AH | CACR-HR10BAB | 4598-006-60813 |

Contact: +86 15270269218