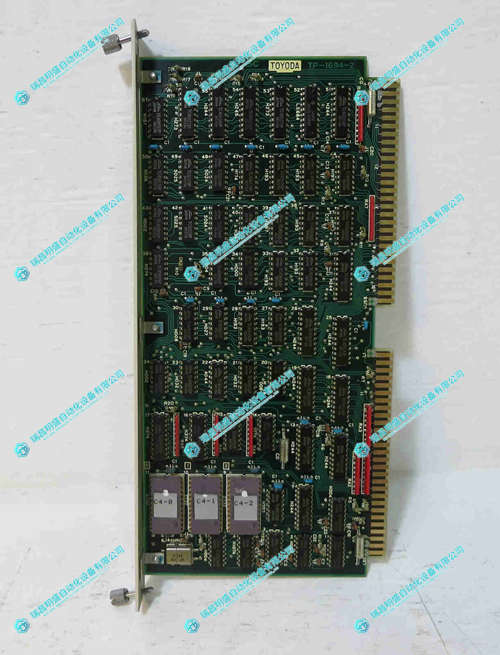

TOYOTA TP-1694-2控制板模块

1.产 品 资 料 介 绍:

- 处理器类型:采用工业级嵌入式处理器或可编程逻辑控制单元,具备强大的数据处理和逻辑运算能力。

- 输入 / 输出接口:配备多路数字量与模拟量接口,可连接多种传感器和执行器,满足不同场景的控制需求。

- 通信接口:支持 RS-232、RS-485、CAN、以太网等常见通信方式,还可兼容丰田专用协议,便于与其他设备进行数据交互。

- 工作电压:采用 DC 24V 的常见工业标准电压,适配工业生产中的供电系统。

- 存储容量:内置程序存储与数据缓冲存储器,可存储控制程序和实时数据,保证系统的稳定运行。

- 工作环境:能在 - 10℃~+55℃的温度范围内正常工作,且具备抗震、防尘设计,可适应恶劣的工业环境。

- 安装方式:提供机架式或模块插拔式安装方式,方便安装、维护和更换。

英文资料:

The TOYOTA TP-1694-2 control board module is the core control unit of Toyota's automation equipment, integrating multiple functions such as signal acquisition, logic operation, execution control, and communication. It is usually installed in robot control cabinets, automated production lines, or specialized process equipment, responsible for coordinating the actions of various execution units, and can achieve precise control and monitoring of the production process. This module emphasizes stability and maintainability in its design, and can adapt to industrial environments with long-term high load operation.

1、 Technical parameters (example, specific values need to be confirmed according to the actual version)

Processor type: Adopting industrial grade embedded processors or programmable logic control units, with powerful data processing and logical operation capabilities.

Input/Output Interface: Equipped with multiple digital and analog interfaces, it can connect various sensors and actuators to meet the control needs of different scenarios.

Communication interface: Supports common communication methods such as RS-232, RS-485, CAN, Ethernet, etc., and is also compatible with Toyota specific protocols for easy data exchange with other devices.

Working voltage: Adopting the common industrial standard voltage of DC 24V, suitable for power supply systems in industrial production.

Storage capacity: Built in program storage and data buffer memory, capable of storing control programs and real-time data, ensuring stable system operation.

Working environment: It can work normally within a temperature range of -10 ℃ to+55 ℃, and has seismic and dustproof design, which can adapt to harsh industrial environments.

Installation method: Provide rack mounted or module plug-in installation methods for easy installation, maintenance, and replacement.

2、 Application scenarios

(1) Control of automobile manufacturing production line

In automated workstations such as welding, assembly, and painting in automotive manufacturing, this module is responsible for logic and action control, enabling synchronous operation and process parameter management of multiple workstations, ensuring efficient and accurate production processes.

(2) Industrial Robot Control System

Used to coordinate joint movements of multi degree of freedom robots, handle tasks such as path planning, speed control, and real-time position feedback, ensuring that the robot can operate accurately according to preset trajectories and parameters.

(3) Testing and Quality Control Equipment

Manage the sensor signal collection and result judgment of the automatic detection workstation, and timely feedback the detection results to the central control system for real-time monitoring and management of product quality.

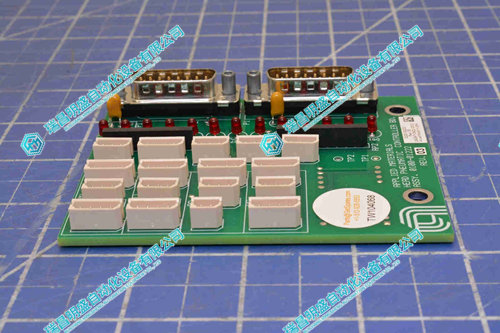

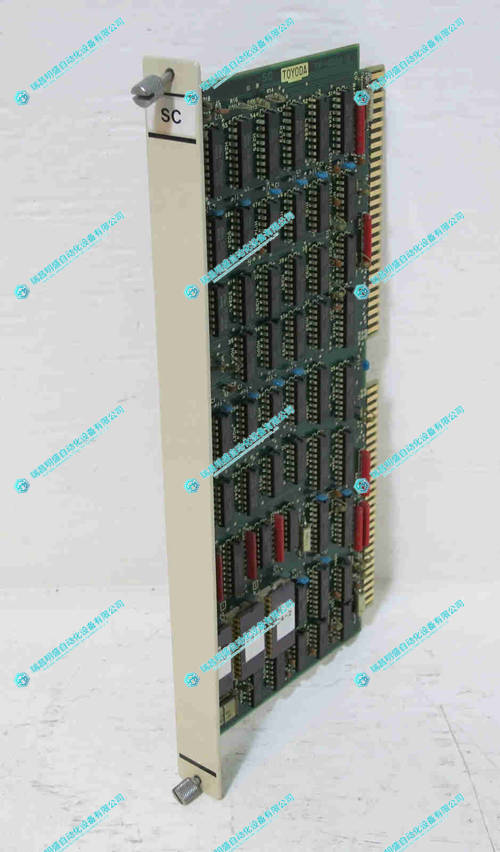

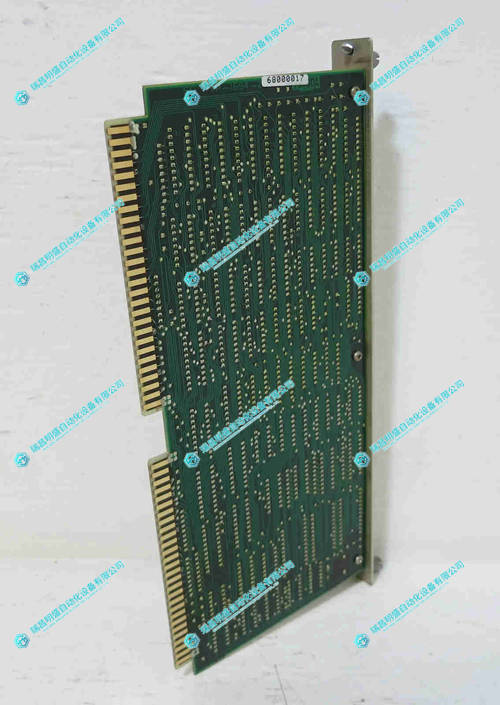

2.产 品 展 示

3.其他产品

INDRAMAT TDM1.3-050-300-W1-000 驱动模块

4.其他英文产品

ABB 3DDE300417 Input/Output Board

GE IS210BPPBH2BMD Controller Module

KOLLMORGEN CP310250 PRD-P310250Z-55 serv

| VC3640-419-1-56C | SC453-037-15 | SC903-050-01 |

| VC3640-405-1-56D | SC453-011-05 | SC933AN-001-01 |

| VC3640-405-1-48C | SC453-029-06 | SC904-001-01 |

| VC3640-278-1-48C | SC452-012-05 | SC904AN-001-01 |

| URRHH | CACR-IR101010F-D | SC933AN-050-01 |

Contact: +86 15270269218