TOYOTA TP-1340-3输出通信模块

1.产 品 资 料 介 绍:

- 通信方式:支持多种工业总线,如 RS-232、RS-485、CAN、以太网,还可适配丰田定制总线协议,兼容性强。

- 输出通道数:具备多路独立信号输出,输出类型为数字量或模拟量,具体依据配置而定,能满足不同场景的信号输出需求。

- 传输速率:最高可达数 Mbps,具体速率取决于所采用的协议,保证数据传输的高效性。

- 电源要求:DC 5V / 12V / 24V(依型号不同而有所差异),可适应不同的供电环境。

- 信号隔离:采用光耦或变压器隔离方式,有效减少信号干扰,提升通信的稳定性。

- 工作环境:可在 - 10℃~+55℃的温度范围内正常工作,且具备抗震、防尘设计,能适应工业生产的复杂环境。

- 接口类型:提供端子排、工业插座或定制连接器等多种接口类型,方便与不同设备连接。

英文资料:

The TOYOTA TP-1340-3 output communication module is an important communication and signal output interface unit in Toyota's automated production equipment. Its main responsibility is to convert the instruction data processed internally by the control system into communication or control signals that can be recognized by external devices, and stably transmit them to the execution end. This module has a wide range of applications in automated production lines, robot control systems, and detection equipment, enabling high-speed and stable data exchange between multiple devices.

1、 Technical parameters (example, subject to actual equipment)

Communication method: Supports multiple industrial buses, such as RS-232, RS-485, CAN, Ethernet, and can also adapt to Toyota customized bus protocols, with strong compatibility.

Number of output channels: It has multiple independent signal outputs, with output types of digital or analog, depending on the configuration, and can meet the signal output requirements of different scenarios.

Transmission rate: up to several Mbps, the specific rate depends on the protocol used to ensure efficient data transmission.

Power requirements: DC 5V/12V/24V (varies depending on the model), can adapt to different power supply environments.

Signal isolation: using optocouplers or transformers for isolation, effectively reducing signal interference and improving communication stability.

Working environment: It can work normally within a temperature range of -10 ℃ to+55 ℃, and has seismic and dustproof design, which can adapt to the complex environment of industrial production.

Interface types: Provides multiple interface types such as terminal blocks, industrial sockets, or customized connectors for easy connection with different devices.

2、 Application scenarios

(1) Production line data communication

Capable of transmitting output signals from PLC or main control system to distributed control units, supporting real-time data exchange between multiple workstations, ensuring efficient collaboration between various processes, and improving the overall operational efficiency of the production line.

(2) Linkage between robots and external devices

It can send motion control instructions to industrial robots to achieve synchronous operation between robots and peripheral devices such as conveying, sorting, and detection, making the entire production system more coordinated and orderly.

(3) Testing and Quality Control System

It can send trigger signals or workpiece identification data to the detection equipment, and output the detection result data to the upper computer or central control system for real-time monitoring and management of product quality.

(4) Remote monitoring and data collection

Output real-time status information from the production site to the monitoring center, support remote device status feedback and control command transmission, facilitate management personnel to timely understand the production situation and conduct remote control.

In summary, the TOYOTA TP-1340-3 output communication module plays an important role in data exchange and signal transmission of Toyota's automated production equipment due to its diverse communication methods, stable transmission performance, and wide range of application scenarios, providing strong support for the efficient and stable operation of automated production.

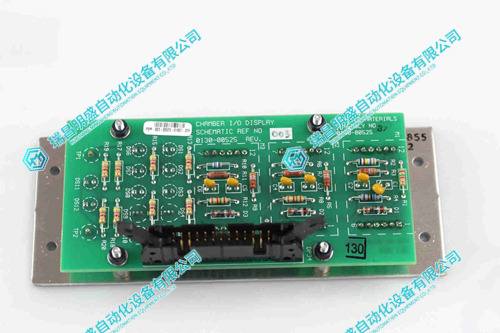

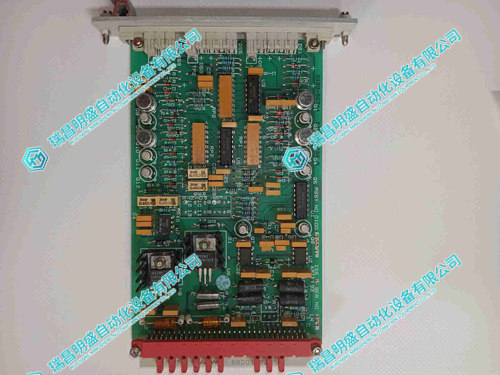

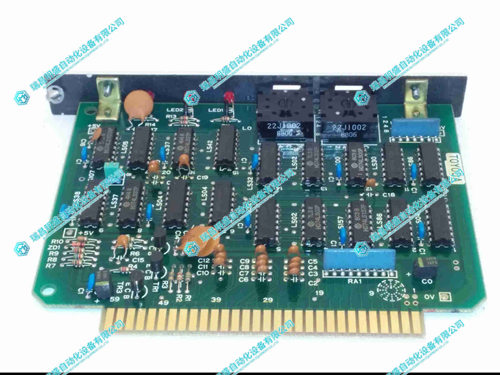

2.产 品 展 示

3.其他产品

INDRAMAT TDM1.3-050-300-W1-000 驱动模块

4.其他英文产品

Schneider 140CP43412A Controller Module

Schneider 140CPS11100 Analog Input Modul

ABB 3DDE300417 Input/Output Board

| VT-VSPA1-1-11B | 6DD1682-0AJ2 | ICS Triplex T3300 |

| VT-VPCD-1-16/V/0/1-P-1 | 6DD1681-0EA1 | Ics triplex t8220 |

| VT3002-1-2X/48F | 6DD1681-0EB3 | ICS TRIPLEX T8311 |

| VT11118-10 | 6DD1681-0GK0 | ICS TRIPLEX T843 |

| VT11023-16 | 6DD1682-0BB0 | ics triplex t7420a |

Contact: +86 15270269218