AMAT Applied Materials AS01391-21-1印刷电路板

1.产 品 资 料 介 绍:

核心规格

功能特点

应用领域

更换与注意事项

AMAT Applied Materials AS01391-21-1印刷电路板 英文资料:

AMAT AS01391-21-1 is a customized printed circuit board specifically designed for semiconductor equipment by Applied Materials Company. It is used for control and signal transmission on platforms such as Centura, Endura, P5000, ensuring stable operation of equipment and accurate data transmission.

Core specifications

Project specifications/parameter notes

Type: Multi layer rigid PCB (6-8 layers), high-speed signal and complex wiring

Stable dielectric properties of substrates with high TG FR-4 or Rogers high-frequency materials

Size 200 × 150 mm (± 0.1 mm) standard chassis adapter

Minimum line width/line spacing 0.10 mm/0.10 mm high-density wiring

The minimum aperture of 0.20 mm (PTH) meets the requirements of BGA and other components

Surface treatment ENIG (chemical nickel/immersion gold) for high reliability and weldability

Solder mask color green (optional blue/black) standard process

Copper foil thickness: 1 oz for inner layer and 2 oz for outer layer, balancing signal and power

Working temperature -20~+60 ℃ Industrial environment

Certification of CE, UL, RoHS international safety standards

Features

High speed signal transmission: differential pair and impedance control (50/90 Ω) are used to ensure low distortion of clock and data signals.

High reliability design: multi-layer grounding and power plane to reduce noise interference.

High precision manufacturing: hole position accuracy ± 0.05 mm, meeting the requirements for high-density device mounting such as BGA and QFP.

Easy to maintain: Surface treated with ENIG for oxidation resistance, corrosion resistance, and extended service life.

Application field

Control and interface module for semiconductor thin film deposition, etching, and ion implantation equipment.

Subsystem circuits for vacuum system, gas flow control, temperature monitoring, etc.

Replacement and precautions

Confirm version: Verify the material code AS01391-21-1 with the version number to ensure electrical compatibility.

Anti static: Wear an anti-static wristband and and operate on the anti-static mat.

Installation positioning: Install according to the chassis positioning hole and connector direction to avoid misalignment.

Welding requirements: The peak temperature for reflow soldering is 245-255 ℃, and the peak temperature for wave soldering is 250-260 ℃ to prevent delamination of the sheet metal.

Testing: Conduct power, signal integrity, and functional testing after installation to ensure no short circuits or signal abnormalities.

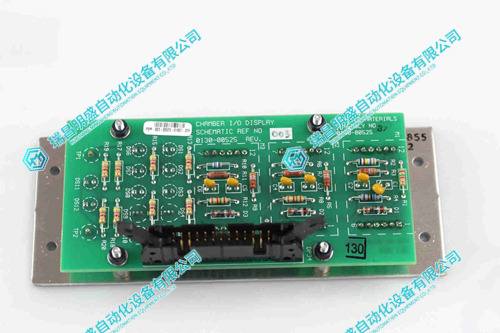

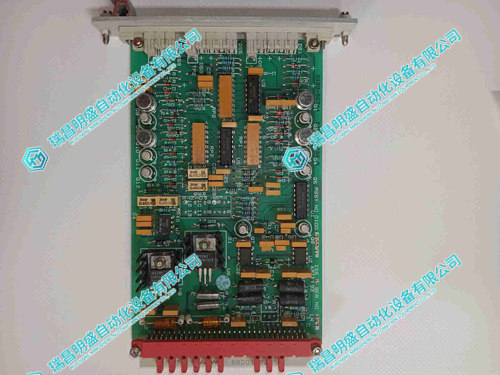

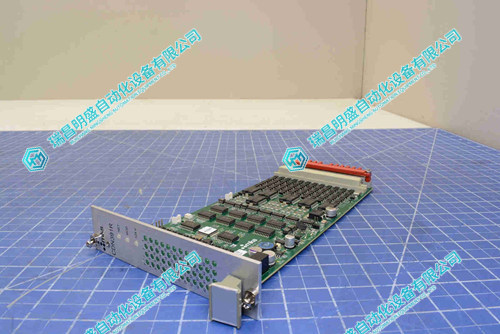

AMAT Applied Materials AS01391-21-1印刷电路板 产品展示

产品视频

3.其他产品

SYN5202a-Z,V221 3BHB006715R0221控制系统模块

Honeywell FC-SCNT01控制器模块

DSPU131 3BSE000355R1 接口板

4.其他英文产品

ABB SDCS-DSL-4-SET digital signal processors

ABB SPA-ZC302 interface module

ABB SX554 3BSE004258R1 Distribution Unit

| CGC 400 | Gespac GESRAM-14C-9318 | PCS115PS-250 |

| CGC 200 | NTRLO2A | |

| CA950-IO | Gespac GESINP-2B 8720 | NTCF01 |

| BAF3644-5081-56BC | Gespac GESCIO-1 8915 | NMFC03 |

| BA3724-4489-56C | GESPAC GESDAC-1 GESDAC1 | NMFC04 |

| BA3648-4650-9-56BC | ADC-12A GESADC-12A 9310 GESPCB-334 | IMMFP03 |

| BA3644-4249-1-48C | GESPAC GESXT-11 GESXT11 | IMMPI01 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218