TOYOTA TP-1875-5数字量控制板卡

1.产 品 资 料 介 绍:

- 精准驱动设备:控制电机、电磁阀等,提供稳定数字量信号,确保机械手臂等设备高精度作业。

- 协同生产流程:汇总工位传感器信号,协调多设备协作,减少等待,提升生产线效率。

- 调控物流设备:控制堆垛机、输送线、分拣设备等,保障货物高效流转,避免故障。

- 支持库存管理:采集仓位、出入库等信息,更新库存数据,助力智能盘点与补货。

- 监测设备状态:采集电力设备、能源仪表信号,反馈运行状况,保障能源供应稳定。

- 执行节能控制:向节能设备发送指令,实现照明、空调等系统的高效调控,降低能耗。

- 管理建筑设备:控制电梯、门禁、消防等设备,实现联动,提升楼宇安全性与智能化。

- 协同环境调控:连接传感器与空调等设备,自动调节室内环境,营造舒适空间。

- 自动化实验流程:向测试仪器发送控制信号,精确控制实验条件与流程。

- 辅助数据处理:采集实验数字量数据,为分析提供准确基础,提高测试可靠性。

英文资料:

Industrial automation production line

Precision driven equipment: Control motors, solenoid valves, etc., provide stable digital signals, and ensure high-precision operation of mechanical arms and other equipment.

Collaborative production process: Summarize workstation sensor signals, coordinate multi device collaboration, reduce waiting, and improve production line efficiency.

Intelligent warehousing and logistics system

Regulating logistics equipment: controlling stacker cranes, conveyor lines, sorting equipment, etc. to ensure efficient flow of goods and avoid malfunctions.

Support inventory management: Collect information on warehouse locations, inbound and outbound inventory, update inventory data, and assist in intelligent inventory and replenishment.

Energy Monitoring and Management System

Monitoring equipment status: Collect signals from power equipment and energy meters, provide feedback on operating conditions, and ensure stable energy supply.

Implement energy-saving control: Send instructions to energy-saving equipment to achieve efficient regulation of lighting, air conditioning, and other systems, reducing energy consumption.

Intelligent Building Control System

Manage building equipment: Control elevators, access control, fire protection and other equipment to achieve linkage, enhance building safety and intelligence.

Collaborative environmental regulation: Connect sensors and air conditioning equipment to automatically adjust indoor environments and create comfortable spaces.

Testing and experimental equipment control

Automated experimental process: Send control signals to testing instruments to precisely control experimental conditions and procedures.

Auxiliary data processing: Collect experimental numerical data to provide accurate basis for analysis and improve testing reliability.

In summary, the TOYOTA TP-1875-5 digital control board is suitable for scenarios that require high control accuracy, collaboration, and data exchange, and is a key component for building efficient intelligent automation systems.

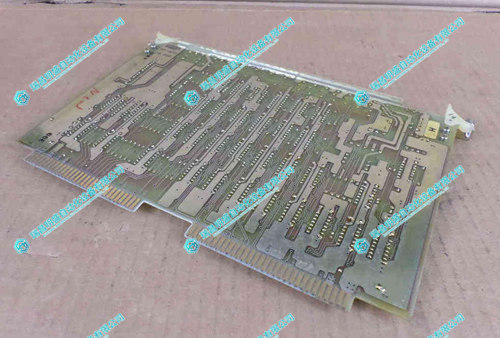

2.产 品 展 示

3.其他产品

INDRAMAT TDM1.3-050-300-W1-000 驱动模块

4.其他英文产品

RADISYS 97-9536-20 Ethernet Port Module

Kollmorgen 6SM37M-6000 servo motor

Radisys ATCA-PP81 controller module

| PMB33F-10214-03 | BK698CPA15B0 | SDCS-CON-2B 3ADT309600R0012 |

| PMB33F-10214-02 | DAO01 | DSTX170 57160001-ADK |

| PMB33F-10214-01 | CI532V02 3BSC970012R1 | MC-TD0R22 51309150-175 |

| PMB33F-10214-00 | DDO02 | 60-0034-01 |

| PMB33F-10201-03 | PP881 3BSE092978R1 | 454108-003 |

Contact: +86 15270269218