TOYOTA TP-1874-4 控制板

1.产 品 资 料 介 绍:

- 设备控制:对车身装配机器人、焊接设备及喷涂机械进行控制,确保各设备精准运行。

- 协同高效:实现多工位协作与动作同步,提高生产线自动化水平和效率。

- 信号管理:管理传送带、分拣机及传感器信号,为生产流程提供数据支撑。

- 监控优化:支持生产流程监控与状态反馈,助力故障检测和生产优化。

- 设备操控:控制堆垛机、搬运机器人及输送设备,保障物流设备有序作业。

- 提升效能:实现物料搬运自动化和精准调度,提升仓储效率和作业安全。

- 系统集成:与 PLC、输入输出模块及其他控制单元集成,构建完整自动化系统。

- 信号处理与监控:支持模拟量、数字量信号处理,用于设备状态采集、报警和远程监控。

- 数据处理:采集和处理传感器、检测仪器数据,为测试提供准确信息。

- 流程自动化:实现自动化测试流程,提高测试精度与可靠性。

英文资料:

Automotive production automation

Equipment control: Control the body assembly robot, welding equipment, and spraying machinery to ensure precise operation of each device.

Collaborative efficiency: achieve multi station collaboration and action synchronization, improve the automation level and efficiency of the production line.

Assembly line equipment management

Signal management: Manage conveyor belts, sorting machines, and sensor signals to provide data support for the production process.

Monitoring optimization: Support production process monitoring and status feedback, assist in fault detection and production optimization.

Intelligent logistics system

Equipment control: Control stacker cranes, handling robots, and conveying equipment to ensure orderly operation of logistics equipment.

Enhance efficiency: Achieve automation and precise scheduling of material handling, improve warehousing efficiency and operational safety.

Industrial automation control

System integration: Integrate with PLC, input/output modules, and other control units to build a complete automation system.

Signal processing and monitoring: Supports analog and digital signal processing for equipment status acquisition, alarm, and remote monitoring.

Testing and Inspection Equipment

Data processing: Collecting and processing sensor and detection instrument data to provide accurate information for testing.

Process automation: Implement automated testing processes to improve testing accuracy and reliability.

In summary, the TOYOTA TP-1874-4 control board is suitable for industrial environments that require high production efficiency, automation level, and equipment coordination, and is the core control unit in automation systems.

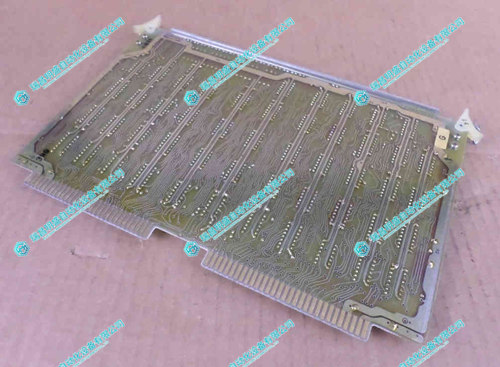

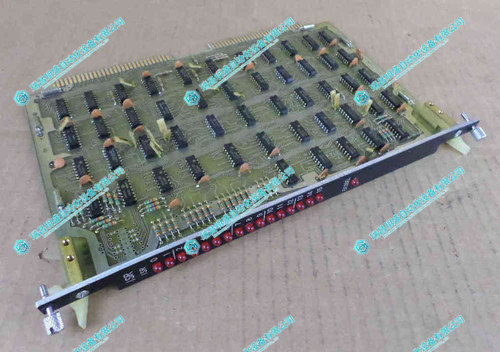

2.产 品 展 示

3.其他产品

4.其他英文产品

ASEA 2668 184-447 Communication Module

RadiSys 61-0475-12 Axis Control Module

RADISYS 97-9536-20 Ethernet Port Module

| PMB33F-20116-00 | 6SC6500-0UC00 | CI615 3BHT300024R1 |

| PMB33F-20101-03 | DSSS170 48970001-A | 6DD2920-0AP0 |

| PMB33F-20101-00 | Gespac GESMFI-1 9119 | TC520 3BSE001449R1 |

| PMB33F-20100-03 | HONEYWELL CC-TDOB01 | 086348-001 |

| PMB33F-20100-02 | DSTA180 57120001-ET | DSQC406 |

| PMB33F-20100-01 | DSQC663 3HAC029818-001/14 | UA C326 AE01 HIEE401481R0001 |

Contact: +86 15270269218