TOYOTA TP-7612-2伺服驱动器

1.产 品 资 料 介 绍:

英文资料:

Characteristics Analysis of TOYOTA TP-7612-2 Servo Drive

Core positioning

TOYOTA TP-7612-2 servo drive is a key equipment responsible for motion control in the field of industrial automation, specifically used to drive and regulate servo motors. With advanced control algorithms and high-speed processing capabilities, it achieves high-precision control of position, speed, and torque. It is like an "engine" for motion control, providing precise power for industrial robots, automated production lines, and mechanical processing equipment, helping to achieve perfect multi axis synchronization and precision movements.

Performance Highlights

Precise control without deviation: supports closed-loop control of position, speed, and torque, and can monitor and adjust the operating status of servo motors at all times, ensuring that every action of mechanical equipment and robots is accurate and meets high-precision operation requirements.

Fast response without delay: completes signal acquisition and control command output at millisecond level speed, and can quickly respond to high-speed motion scenes and multi axis synchronous operations, ensuring the coherence and coordination of the motion process.

Multi axis collaboration is more flexible: it can support single axis or multi axis system drive, whether it is simple single axis motion or complex multi axis linkage, it can easily cope with, achieve coordinated control of complex mechanical motion, and enhance the multifunctionality of equipment.

Comprehensive safety protection: Built in overcurrent, overvoltage, short circuit, and overheating protection mechanisms, like installing a "safety shield" on the equipment. Once an abnormal situation occurs, protective measures can be immediately activated, greatly improving the reliability of the equipment and the entire system.

Ultra convenient installation and expansion: adopting a plug-in installation design, making daily maintenance and system expansion simple and efficient, while seamlessly integrating with TOYOTA series controllers and I/O modules, reducing docking troubles.

Strong anti-interference ability: designed according to industrial standards, it has excellent anti electromagnetic interference and anti vibration performance, and can always maintain stable operation in complex industrial environments, ensuring long-term work without "chain failure".

Applicable fields

In the multi axis motion control of industrial robots, it can accurately drive the operation of each axis, allowing the robot to flexibly complete various complex actions; Provide stable power for servo drives in automated assembly lines and production lines to ensure smooth and efficient production processes; Applied to CNC machine tools and processing equipment, it can achieve precise positioning of workpieces and improve machining accuracy; Being able to control the movement of logistics transportation and handling equipment, making their operation smoother and more orderly; In testing and inspection equipment, high-speed position and torque control can be achieved to ensure the accuracy of test results. With high precision, high response, and high reliability, it has become an indispensable key motion control unit in TOYOTA automation systems.

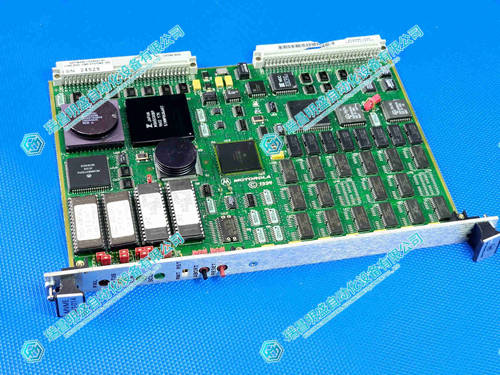

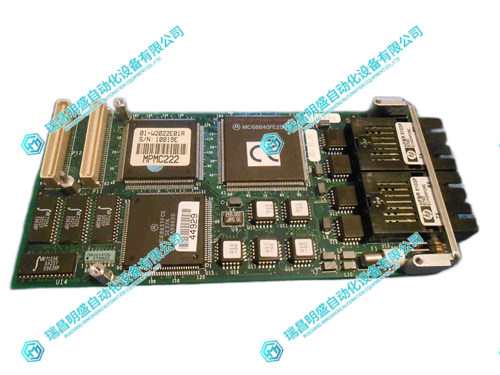

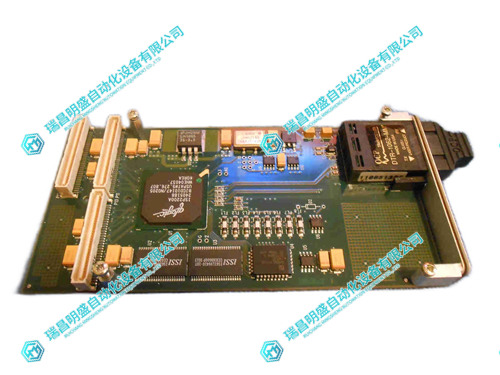

2.产 品 展 示

3.其他产品

4.其他英文产品

ASEA DSQC100 connector backplane

ASEA 2668 184-447 Communication Module

RadiSys 61-0475-12 Axis Control Module

| K42HCHM-LNK-NS-00 | AMAT 0100-91119 | INICT13A |

| K34HRHJ-LNK-NS-00 | AMAT 0100-00579 | IMSED01 |

| K33SRFJ-LSS-N2-02 | AMAT 0100-00379 | IMSET01 |

| K33HRFG-LNK-NS-00 | AMAT 0100-71275 | IMCPM02 |

| K33HLHM-LNK-NS-00 | AMAT 0100-40029 | INSEM01 |

| K33HLHJ-LNK-NS-01 | AMAT 0100-14006 | INICT12 |

Contact: +86 15270269218