TOYOTA TP-7644-3 驱动器

1.产 品 资 料 介 绍:

英文资料:

Analysis of TOYOTA TP-7644-3 Driver Characteristics

Core functions

The TOYOTA TP-7644-3 driver is the core equipment for driving motors and controlling mechanical actions in the field of industrial automation. It can provide power to motors and accurately regulate the operation of mechanical systems. With high-speed response, precise control, and reliable protection, it plays a key role in robot systems, production line automation, and mechanical processing equipment, helping to achieve efficient and precise motion control.

Performance advantages

High precision motion control: It can accurately control the position, speed, and torque. Through detailed parameter adjustment, it ensures accurate positioning, stable speed, and appropriate torque of mechanical equipment or robots during the motion process, meeting the requirements of high-precision operations.

Fast response without lag: It can complete the acquisition and processing of control signals in milliseconds. When facing multi axis synchronization and complex action control, it can quickly adjust the output to ensure the coordinated and consistent actions of various components, and improve overall operational efficiency.

Strong multi axis adaptability: It can drive single axis motors and also adapt to multi axis motor systems, supporting multi axis coordinated motion, easily meeting the linkage requirements of various axes in complex industrial processes, and enhancing the multifunctionality of equipment.

Reliable and durable performance: Made with industrial grade components, it has the characteristics of high temperature resistance, dust prevention, and vibration resistance. At the same time, it has excellent resistance to electromagnetic interference and can operate stably for a long time in harsh industrial environments, reducing downtime due to faults.

Comprehensive safety protection: Built in overcurrent, overvoltage, short circuit, and overheating protection functions. When abnormal situations are detected, the output can be cut off or protective measures can be taken in a timely manner, effectively protecting the safety of the driver itself and connected devices, and reducing the risk of damage.

Easy installation and expansion: Adopting a plug-in design, it is convenient for daily maintenance and system expansion, and can be seamlessly integrated with TOYOTA series controllers and I/O modules, simplifying the system construction process and improving integration efficiency.

Applicable scenarios

In industrial robots, joint motors can be driven to achieve precise action execution; Used for automated production lines, it can control the movement of conveying equipment, assembly machinery, etc., ensuring stable production rhythm; Applied to mechanical processing equipment, it can regulate the movement of cutting tools or workbenches to improve machining accuracy; In the logistics handling system, it can drive conveyor rollers, robotic arms, etc. to ensure efficient and orderly material handling. Its high precision, responsiveness, and reliability make it a key motion control component in TOYOTA automation systems, suitable for various industrial automation scenarios.

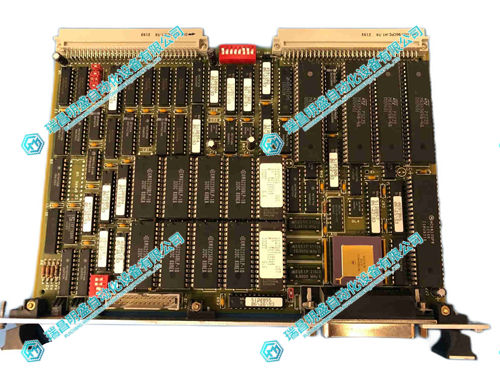

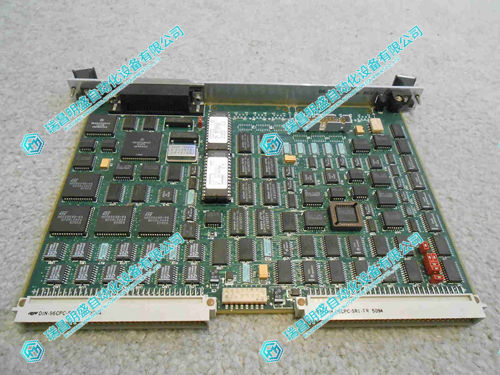

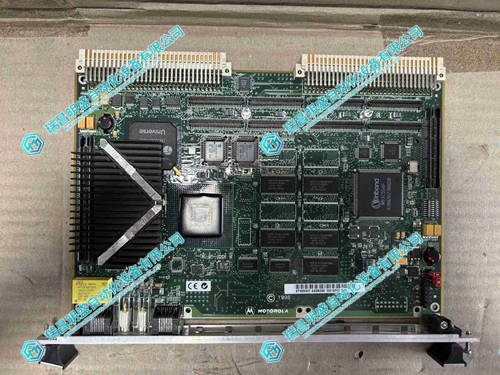

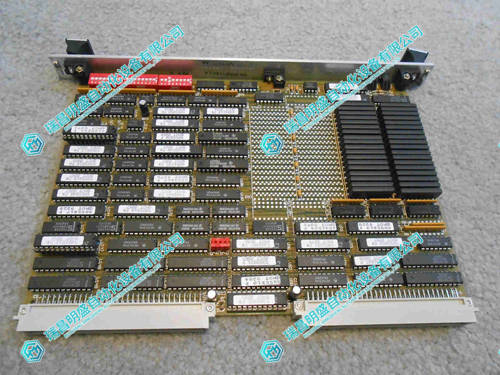

2.产 品 展 示

3.其他产品

4.其他英文产品

RadiSys 61-0475-12 Axis Control Module

RADISYS 97-9536-20 Ethernet Port Module

Kollmorgen 6SM37M-6000 servo motor

| K32HRHJ-LSS-NS-02 | AMAT 0100-90977 | IMFEC12 |

| K32HRFJ-LEK-M2-00 | AMAT 0100-00496 | BRC300 |

| K32HLLL-LNK-NS-00 | AMAT 0100-00071 | INNIS21 |

| K32HLLK-LNK-NS-01 | S6001 | INNPM12 |

| K32HLFM-LNK-NS-00 | SJC4A41-81 | 6ES5-431-8MC11 |

Contact: +86 15270269218