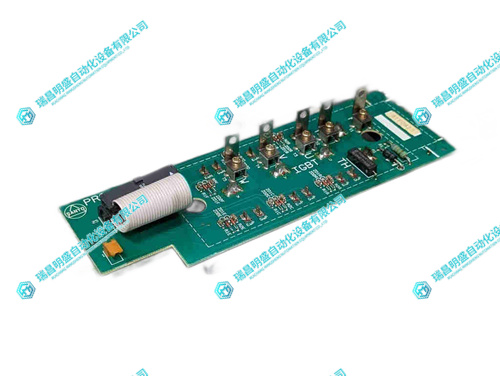

TOYOTA PRS-3014C定位控制器板

1.产 品 资 料 介 绍:

英文资料:

Characteristic Analysis of TOYOTA PRS-3014C Positioning Controller Board

Core functions

The TOYOTA PRS-3014C positioning controller board is a core unit dedicated to precision motion control and position management in industrial automation systems. It can capture input signals in real time, accurately calculate motion instructions, and drive the execution mechanism to operate efficiently, thereby achieving high-precision position control and multi axis synchronous operation, providing stable and reliable positioning support for robot systems, automated production lines, and mechanical processing equipment.

Performance Highlights

Accurate positioning without deviation: Supports closed-loop control of the position, speed, and torque of servo motors, ensuring accurate and precise motion trajectories of robotic arms and handling equipment through real-time feedback and adjustment, meeting the stringent requirements of high-precision work scenarios.

High speed response is more timely: the signal processing and action response speed can reach millisecond level, which can quickly respond to the high-speed production rhythm and multi axis synchronous control requirements, ensuring that the equipment still maintains the coordination and accuracy of actions in high-frequency operation.

Multi axis collaboration is more flexible: it can support single axis or multi axis motion control, whether it is simple single axis positioning or complex multi axis linkage, it can be easily controlled, achieve synchronous action of complex mechanical equipment, and improve the overall operating efficiency of the system.

Rich interfaces and wide adaptability: equipped with digital, analog, and communication interfaces, it can smoothly connect with various devices, especially seamlessly integrate with TOYOTA series I/O modules and servo drives, simplifying the system integration process.

Stable, reliable and anti-interference: Designed with industrial grade components, it has excellent electromagnetic interference resistance and can operate stably for a long time in harsh industrial environments such as high temperature and vibration, reducing failures caused by environmental factors.

Comprehensive safety protection: Built in overcurrent, overvoltage, short circuit, and overheating protection mechanisms, which can quickly activate protective measures when the system encounters abnormalities, effectively ensuring the safety of the controller and the entire system, and reducing the risk of equipment damage.

Application Fields

In industrial robots, precise control of the motion positioning of each axis enables the robot to perform fine operations; Used for automated assembly lines and production lines, it can achieve precise action control of equipment and ensure accurate docking in the production process; Responsible for motion management in mechanical processing and handling equipment, improving the accuracy and efficiency of processing and handling; Suitable for high-precision positioning of testing and inspection equipment, ensuring the accuracy of test data; In logistics and warehousing automation systems, equipment actions can be coordinated to optimize logistics operation processes. With high precision, reliability, and multi interface compatibility, it has become the core motion and positioning control unit in TOYOTA automation systems and industrial equipment.

2.产 品 展 示

3.其他产品

4.其他英文产品

Kollmorgen 6SM37M-6000 servo motor

Radisys ATCA-PP81 controller module

AMAT 0190-24282 encoder module

| K32HCHL-LNK-NS-01 | SPAE-1215-104 | IEPDS01 |

| K32HCHL-LNK-NS-00 | S6100-NA | BRC-300 |

| K32HCHL-LEK-M2-01 | SERVOSTAR-606 | IIMCP02 |

| K32HCHL-LEK-M2-00 | Gespac GESTIM-1A TIM-1AC/24 | IMAOM01 |

| K32HCHK-LNK-NS-01 | GESPAC GESDAC-2A | IEMMU21 |

| K32HCHK-LNK-NS-00 | GESPAC GESMEM-3A | IMDSI14 |

| K32HCHK-LEK-M2-01 | SR06200-000000 | IMHSS03 |

Contact: +86 15270269218