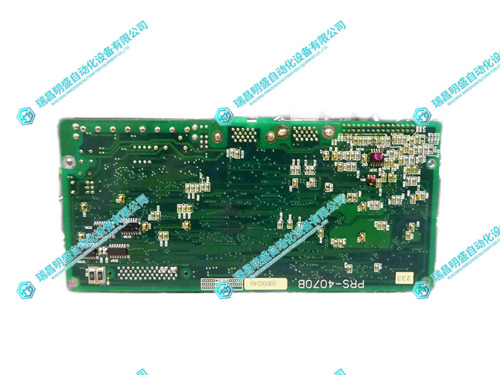

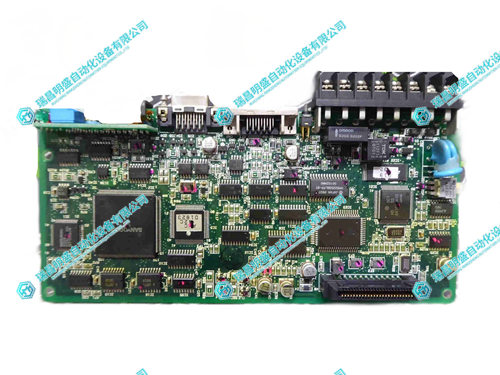

TOYOTA PRS-4070B轴控制板

1.产 品 资 料 介 绍:

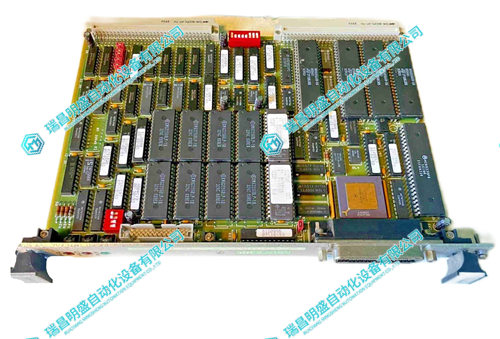

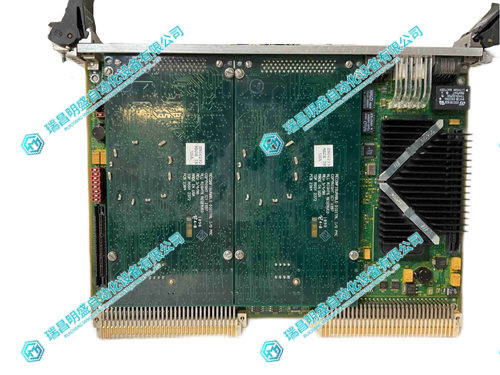

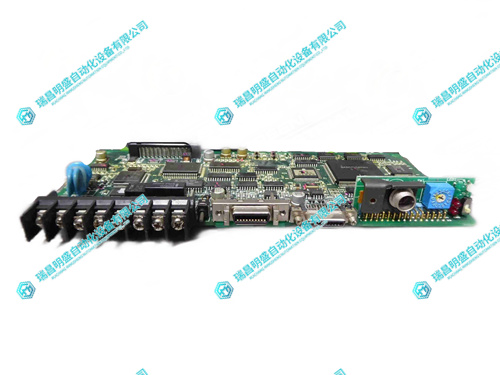

Characteristic analysis of TOYOTA PRS-4070B axis control board

Core functions

The TOYOTA PRS-4070B axis control board is a core component dedicated to multi axis motion control in the field of industrial automation, capable of precise independent control or synchronous coordination of multiple axes. It provides stable and reliable control support for industrial scenes that require precise motion and complex synchronous operations by receiving control instructions, processing motion parameters, and driving each axis to run according to preset trajectories and speeds. It is the key to multi axis motion control in the TOYOTA system.

Performance Highlights

High precision axis control capability: With excellent axis control accuracy, whether it is independent control of a single axis or synchronous coordination of multiple axes, it can ensure the accuracy of the motion trajectory and meet the requirements for high-precision actions in industrial production.

Multi axis collaborative efficiency: It can efficiently handle the collaborative relationships between multiple axes, allowing for seamless coordination of actions between different axes. In complex industrial processes such as multi axis linkage machining and synchronous handling, it can maintain efficient operation.

Quick and sensitive response: The response speed to control instructions is fast, and the motion status of each axis can be adjusted in a timely manner based on input signals, ensuring the timeliness and accuracy of axis actions in high-speed motion and complex operations.

Strong adaptability: It can be used in conjunction with various types of driving devices and sensors, and can flexibly adapt to different industrial automation equipment, such as robots, processing machines, assembly line equipment, etc.

Stable and reliable operation: Adopting industrial grade design standards, high-quality components are selected, with good anti-interference, high temperature resistance, and vibration resistance. It can work stably for a long time in harsh industrial environments, reducing the occurrence of faults.

Application field details

Multi axis robot system: responsible for independent or synchronous control of various joints and axes of industrial robots, supporting high-speed and precise movement of robotic arms and precise operation of end tools, enabling robots to flexibly complete various complex tasks.

Precision machining equipment: Control the main and auxiliary axes of CNC machine tools or machining centers to achieve multi axis coordinated machining such as cutting, milling, and drilling, improve machining accuracy and efficiency, and ensure the quality of machined parts.

Automated assembly line: drives the linear and rotational axes of assembly equipment, coordinates handling, positioning, and assembly actions, ensures smooth connection between various links, improves production efficiency, and meets the high-precision requirements of automated assembly.

Detection and testing system: Control the motion axis of experimental equipment or testing bench, achieve high-precision positioning and multi axis synchronous measurement, ensure the accuracy and reliability of detection data, and provide strong support for testing work.

Packaging and handling equipment: Manage the axis movements of conveying, sorting, and stacking machinery, improve the accuracy and stability of logistics equipment movements, and make the packaging and handling process more efficient and orderly.

With its high-precision axis control capability and multi axis coordination processing ability, the PRS-4070B axis control board is suitable for industrial automation scenarios that require precise motion and complex synchronous operations. It is a key core component of multi axis motion control in the TOYOTA system.

2.产 品 展 示

3.其他产品

4.其他英文产品

AMAT 0190-11415 Digital Input Module

ASEA 2668 184-447 Communication Module

| K31HRLG-LDK-NS-00 | 6SC6508-4AA02 | IMSED01 |

| K31HRHJ-LNK-NS-00 | 6SC6502-0AF01 | IEPDF02 |

| K31HMHJ-LNK-NS-00 | 6SC6190-0FB61 | IEPAS02 |

| K31HLLG-LNK-NS-01 | PSR45-220 | IMASI02 |

| K31HLHJ-LNK-NS-00 | SS2000MD4M-0 | INICT12 |

| K31HCHJ-LNK-NS-01 | PSR45A-212 | IMCPM02 |

Contact: +86 15270269218