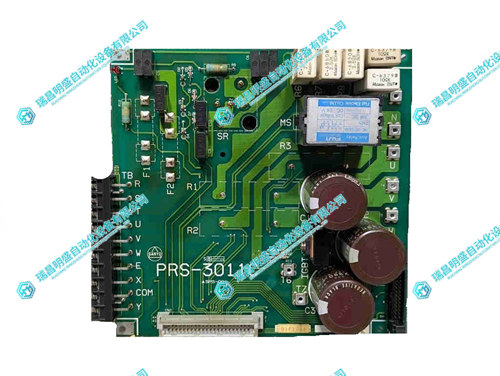

TOYOTA PRS-3011C定位配电板

1.产 品 资 料 介 绍:

Characteristic Analysis of TOYOTA PRS-3011C Positioning Distribution Board

Core functions

TOYOTA PRS-3011C positioning distribution board is the "energy supply and signal scheduling core" in industrial automation positioning control systems, mainly providing stable power support for positioning controllers, drivers, and related execution units, while also undertaking the distribution of control signals. It is like the "logistics center" of a positioning system, ensuring high-precision and high reliability operation of the entire positioning system through stable power supply and orderly signal distribution, laying a solid foundation for various industrial automation positioning scenarios.

Performance Highlights

The power supply is as stable as a rock: it delivers stable and continuous current to the positioning controller and drive module, like a precise "power regulator", which can effectively reduce the interference of power supply fluctuations on high-precision positioning, keeping the positioning equipment in a stable state in power supply and providing solid guarantee for precise operation.

Signal distribution is well-organized: The multi-channel signals output by the positioning controller are centrally managed and distributed to ensure that the signals can be accurately and timely transmitted to various executing components, especially when supporting multi axis synchronous actions, which can make the motion coordination of each axis more coordinated and greatly improve the motion coordination of the system.

Strong adaptability to industrial environments: adopting professional designs that are resistant to high temperatures, dust, and vibration, with excellent resistance to electromagnetic interference. Even in complex and changing industrial environments, it can maintain stable working performance without being overly affected by external environmental factors.

Comprehensive and reliable safety protection: Built in overcurrent, overvoltage, and short-circuit protection mechanisms can quickly activate protective measures when abnormal situations occur in the power system, like a sturdy "safety barrier", ensuring the safe operation of controllers and execution modules and reducing the risk of equipment damage.

Modular design is flexible and convenient: equipped with plug-in interfaces, making installation, maintenance, and system upgrades simple and efficient. At the same time, it can be flexibly expanded according to actual needs, easily adapting to different system configurations, enhancing the scalability and applicability of the system.

Application scenarios

In the robot positioning system, it provides stable power and signal support for the precise positioning of the robot, ensuring that the robot can accurately reach the designated position; Suitable for multi axis mechanical motion control, coordinating the power supply and signal transmission of each axis to ensure synchronization and accuracy of multi axis motion; Provide basic support for various positioning devices in automated production lines to improve the positioning accuracy and operational efficiency of the production line; Can be used for handling systems to ensure the stability and reliability of handling equipment during the positioning process; In precision machining equipment, ensuring the precise positioning of machined parts. With reliable power supply, centralized signal management, and safety protection features, it provides stable and efficient basic support for TOYOTA positioning control system, and is a key module for achieving high-precision automation control.

2.产 品 展 示

3.其他产品

4.其他英文产品

ASEA 2668 184-447 Communication Module

RADISYS EXM-HDEXM-MX Memory Module

VMIVME-2540 Intelligent Counter Controll

| IS220PPROH1A IS220PPROS1B | SI-255 | IMMFP12 |

| IS220PPRFH1A IS220PPRFH1B | SV3405-10000 | IMDS014 |

| IS220PPRAS1B | PS-3306I-E | BRC400 |

| IS220PPRAS1A IS220PPRAS1B | SSA-400720 | BRC-200 |

| IS220PPRAH1A IS220PPRAS18 | P8101Z22210020 | IMAS011 |

| IS220PHIRAH1A IS220PHRAH1B | SR10200-000000 | BRC300 |

Contact: +86 15270269218