TOYOTA TAP3001-0输出板

1.产 品 资 料 介 绍:

英文资料:

Analysis of TOYOTA TAP3001-0 Output Board Characteristics

Core functions

The TOYOTA TAP3001-0 output board is a key output interface module that connects controllers and execution devices in industrial automation systems. With stable and reliable multi-channel output capabilities, it converts the instructions issued by the controller into specific action signals, drives various execution devices to operate, and achieves efficient linkage between the two, providing strong support for the smooth operation of industrial automation and robot systems.

Performance Highlights

Strong multi-channel output: With multiple output channels, it can drive multiple execution devices simultaneously, meeting the needs of collaborative work among multiple devices in industrial scenarios. The output is stable and reliable, ensuring accurate and error free actions of each device.

Quick and efficient response: The response speed to controller instructions is fast, and electrical signals can be quickly transmitted to executing devices. It supports high-frequency output operations and adapts to the rhythm of high-speed automated production.

Excellent compatibility performance: It can be connected to various types of execution devices, such as robotic arms, end effectors, conveying equipment, etc., and can also perfectly cooperate with TOYOTA series controllers, with strong compatibility and reducing the trouble of system integration.

Stable and reliable operation: adopting industrial grade design, selecting high-quality components, with good anti-interference, temperature resistance, and vibration resistance performance, it can work stably for a long time in complex industrial environments, ensuring the continuity and accuracy of output signals.

Safe operation: equipped with certain safety protection mechanisms, able to respond to unexpected situations during the output process, protect oneself and connected execution devices, and reduce the risk of failure.

Application scenario details

Industrial automation production line: used to control the action output of mechanical arms, conveyor belts, sorting machines and other equipment, accurately control the switches of each process in the production process, ensure the orderly connection of production links, and improve production efficiency.

Robot execution unit control: drives the end effector or auxiliary device of the robot, closely cooperates with the controller, realizes complex action logic and task execution, and enables the robot to accurately complete grasping, placement and other operations.

Packaging and assembly equipment: Control the output actions of packaging machinery, feeding devices, or assembly mechanisms, support high-frequency, multi-channel output operations, and meet the fast and precise action requirements during packaging and assembly processes.

Testing and Inspection System: Output control signals to drive testing fixtures, sensors, or electrical loads, ensuring efficient and accurate automated testing processes and providing support for the reliability of testing results.

Logistics and handling equipment: Control the electrical execution actions of conveyor lines, stackers, and sorting equipment to improve the accuracy and stability of logistics system operations, making material transportation, stacking, and sorting more efficient and orderly.

The TAP3001-0 output board, with its stable and reliable multi-channel output capability, has become a key output interface module in TOYOTA industrial automation and robot systems, effectively promoting efficient linkage between controllers and execution devices in automation systems.

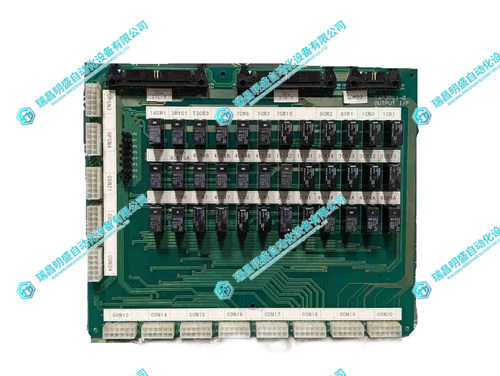

2.产 品 展 示

3.其他产品

4.其他英文产品

VMIVME-2540 Intelligent Counter Controll

Mitsubishi MELFA CR1-571 Large Contactor

| IS220PCAAH1A IS220PCAAH1B | SERVOSTAR-341 | IEPEP03 |

| IS220PAOCHIA IS220PAOCH1B | S5001 | BUS MONITOR |

| IS220PAICH2A IS220PAICH2B | 52010-00 | IMDSI02 |

| IS220PAICH1A IS220PAICH1B | SS2000PCI-2 | IMSET01 |

| IS215UCVGH1A | HA42A6-R233 | IMDS001 |

| IS215UCVFH2AB | SE06200-000000 | IMASI03 |

Contact: +86 15270269218