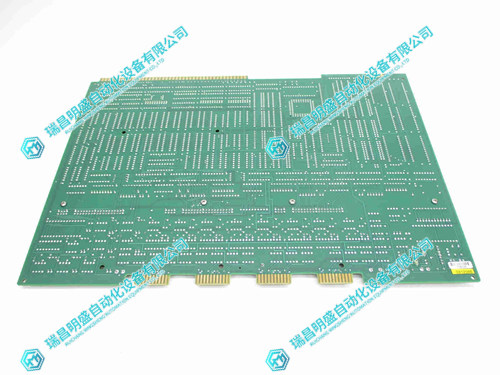

GIDDINGS & LEWIS 502-03417-03智能伺服控制

1.产 品 资 料 介 绍:

GIDDINGS & LEWIS 502-03417-03 智能伺服控制模块概述

英文资料:

GIDINGS&LEWIS 502-03417-03 Overview of Intelligent Servo Control Module

GIDINGS&LEWIS 502-03417-03 intelligent servo control module is a high-performance motion control unit in industrial automation systems, focusing on precise management of servo motors. It uses closed-loop control to achieve intelligent adjustment of speed, position, and torque. It can not only drive a single servo motor, but also support multi axis coordinated control. It is an indispensable core component in CNC machine tools, robots, and complex automated production lines.

In terms of technical features, the intelligent closed-loop control function of this module is outstanding, which can automatically adjust the output according to feedback signals, ensuring the accuracy and stability of motor action, and keeping the equipment in precise motion trajectory during operation. Strong multi axis coordination capability, capable of simultaneously controlling multiple servo motors, easily achieving synchronous action and complex trajectory control, meeting the multi-dimensional motion requirements in complex industrial scenarios.

Rich interface configuration, providing digital input/output interfaces and encoder feedback interfaces, can smoothly connect with controllers and I/O modules, and build a complete control chain. High speed response characteristics are significant, with low processing delay for control signals, ensuring fast and smooth motor action, and improving the dynamic performance of the equipment.

The protection mechanism is complete, with overcurrent, overvoltage, overtemperature, and short-circuit protection functions, which can take timely measures in various abnormal situations to ensure the safe operation of the system. Strong adaptability to industrial environments, resistant to vibration, high temperature, and electromagnetic interference, capable of stable operation in harsh industrial environments without being affected by environmental factors. Modular design makes it easy to install and replace, while supporting extended functional modules, making it convenient for system upgrades and adapting to constantly changing production needs.

In the application field, in terms of CNC machine tools, it can accurately control the spindle, tool magazine, and multi axis feed, assist in completing complex machining tasks, and ensure the machining accuracy of parts; In the automated assembly line, servo driven conveying, clamping, and sorting actions can be controlled to improve production efficiency and achieve efficient operation of the production line; In industrial robot systems, driving the joints of robotic arms and end effectors enables complex action sequences and multi task collaboration, enhancing the flexibility of robot operations; In packaging and printing equipment, precise control of feeding, cutting, and positioning mechanisms is achieved to achieve efficient synchronous operations and ensure product quality; In the experimental and testing system, precise control and status monitoring are carried out on the motion platform, testing bench, and precision equipment to ensure the accuracy of experimental data.

2.产 品 展 示

3.其他产品

4.其他英文产品

AMAT 0190-11415 Digital Input Module

ASEA 2668 184-447 Communication Module

| PMB33F-10216-02 | CP451-51 | 6DD2920-0AR1 |

| PMB33F-10216-01 | PRAXIS 98.6.049.800 | RF616 3BSE010997R1 |

| PMB33F-10216-00 | DLM02 | TU515 1SAP212200R0001 |

| PMB33F-10214-03 | BK698CPA15B0 | SDCS-CON-2B 3ADT309600R0012 |

| PMB33F-10214-02 | DAO01 | DSTX170 57160001-ADK |

| PMB33F-10214-01 | CI532V02 3BSC970012R1 | MC-TD0R22 51309150-175 |

Contact: +86 15270269218