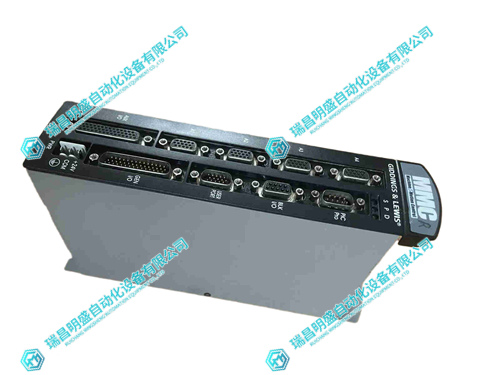

GIDDINGS & LEWIS 503-26606-40分析装置

1.产 品 资 料 介 绍:

GIDDINGS & LEWIS 503-26606-40 分析装置概述

英文资料:

Overview of GIDINGS&LEWIS 503-26606-40 Analysis Device

The GIDINGS&LEWIS 503-26606-40 analysis device is a monitoring and diagnostic module designed specifically for industrial automation systems, with the core function of collecting and analyzing equipment operation data. It can process various signals in machine tools, production lines, or experimental equipment in real time, provide equipment operating status, performance indicators, and fault diagnosis information, assist control systems in optimizing process flow, improve production efficiency, and play a key role in automated factories, testing laboratories, and high-precision processing environments.

In terms of technical characteristics, the device has strong signal acquisition capabilities, supports multiple digital and analog inputs, and can capture various status data of the equipment in real time, providing comprehensive basis for subsequent analysis. In terms of data processing, the built-in high-speed processor can perform real-time analysis and calculation on the collected data, quickly obtaining valuable information. The communication interface supports industrial Ethernet and fieldbus protocols, enabling smooth data exchange with the control system or upper computer, ensuring timely and efficient information transmission.

The alarm and indication function is practical, which can automatically trigger alarms based on preset thresholds and indicate the status through LED or interface signals, making it convenient for staff to timely grasp equipment abnormalities. Outstanding industrial adaptability, with anti-interference, high temperature resistance, and vibration resistance design, it can work stably in complex industrial environments without being affected by harsh conditions. Modular design makes it easy to integrate into existing control architectures, while supporting expansion and system upgrades, and can flexibly adapt to industrial systems of different scales and requirements.

In the field of CNC machine tool monitoring, it can analyze the operating status of the spindle, tool magazine, and feed system in real time, detect potential problems in a timely manner, and ensure machining accuracy and equipment safety; During the monitoring of automated production lines, production equipment data can be collected to achieve fault diagnosis and maintenance warning, reduce production line downtime, and improve production continuity; In industrial robot systems, analyzing motion accuracy, joint loads, and actuator states provides data support for optimizing motion control and improving robot performance; In terms of experimental and testing equipment, real-time collection and analysis of operating parameters of experimental devices or test benches are carried out to ensure the accuracy and reliability of experimental data; In the factory information system, the collected data is uploaded to MES or control center to provide data support for production management and process optimization, promoting intelligent operation of the factory.

2.产 品 展 示

3.其他产品

jetter JM-204-480-JC310-S1伺服驱动器

4.其他英文产品

IC3600EPSS1B power supply boar

| PMB33F-20200-02 | Gespac ADC-12A GESADC-12A | 3500/42M |

| PMB33F-20200-00 | MDI32BIS | 6DD2920-0AR3 |

| PMB33F-20116-03 | DSCA190V 57310001-PK | PM253V01 |

| PMB33F-20116-01 | HONEYWELL 05701-A-0511 | 6DD2920-0AN1 |

| PMB33F-20116-00 | 6SC6500-0UC00 | CI615 3BHT300024R1 |

| PMB33F-20101-03 | DSSS170 48970001-A | 6DD2920-0AP0 |

Contact: +86 15270269218