GIDDINGS & LEWIS HSM620无刷伺服电机

1.产 品 资 料 介 绍:

GIDDINGS & LEWIS HSM620 无刷伺服电机

核心特点

应用场景

英文资料:

GIDINGS&LEWIS HSM620 brushless servo motor

Core Features

High precision control: Built in high-resolution photoelectric encoder or parser, combined with closed-loop control, can achieve micrometer level positioning accuracy, ensuring accurate tracking of instruction trajectories during high-speed operation of the equipment.

High dynamic response: using rare earth permanent magnet materials and optimized electromagnetic design, the rotor inertia is low, the response speed is fast, and the start stop and speed change can be completed in milliseconds, suitable for industrial robots and other scenarios that require fast action.

Wide power coverage: Provides medium to high power levels, suitable for high inertia loads, high power density, smaller volume under the same power, and can meet different needs from precision operation to heavy-duty machining.

Flexible control mode: supports switching between position, speed, and torque modes, which can be adjusted according to different process requirements, such as precise positioning in automated production lines and maintaining constant speed in printing equipment.

High reliability: With a protection level of IP65, it can resist dust and water splashes and adapt to harsh industrial environments; Equipped with overcurrent, overheating, undervoltage and other protection functions, it can quickly trigger safety braking and extend equipment life.

Brushless advantages: adopting electronic commutation, no mechanical wear, with a lifespan of over 20000 hours, low maintenance costs, and reduced electromagnetic interference, suitable for environmentally sensitive scenarios.

Strong compatibility: The interface is standardized and can be directly adapted to G&L series servo drives, achieving fast integration and ensuring synchronous motor actions in multi axis linkage systems.

Wide voltage adaptation: Supports 230V/400V industrial power supply, can adapt to ± 10% voltage fluctuations, and can still operate stably in unstable power environments.

Low noise operation: By optimizing mechanical design, low noise during operation helps create a quiet production environment.

Application scenarios

Widely used in CNC machine tools (driving spindles or feed axes to meet high-speed cutting and heavy load processing), automated production lines (ensuring synchronization and efficiency in assembly, conveying, and other processes), industrial robots (as joint drivers, supporting complex trajectories and high-precision positioning), packaging and printing equipment (achieving high-speed paper feeding, cutting, and positioning), textile machinery (providing stable driving in winding, feeding, and other processes), as well as testing platforms and experimental equipment (meeting high-precision and high dynamic motion control requirements).

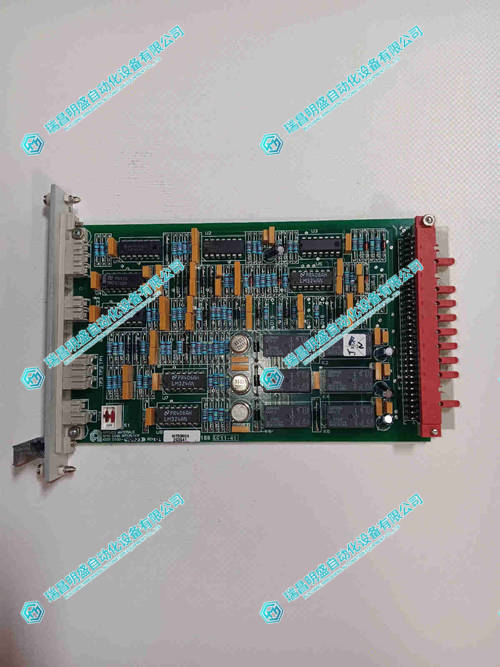

2.产 品 展 示

3.其他产品

4.其他英文产品

Asea EB0524B01 driver input power board

ABB UN1024c-P Remote Terminal Module

ABB 70BK03c-E Control I/O Module

| PMB31B-10214-02 | NRI002 | 57160001-DL DSDI 302 |

| PMB31B-10214-01 | AMAT 0100-03267 | 57160001-BN DSTD 151 |

| PMB31B-10214-00 | NTAI05 | M22NRXC-LDN-M1-00 |

| PMB31B-10201-03 | AMAT 0100-76085 | PFVL141R |

| PMB31B-10201-02 | INIIT02 | 57120001-NY DSTA 121 |

| PMB31B-10201-01 | FPR3315101R1032 | 57160001-NB DSTD 115 |

Contact: +86 15270269218