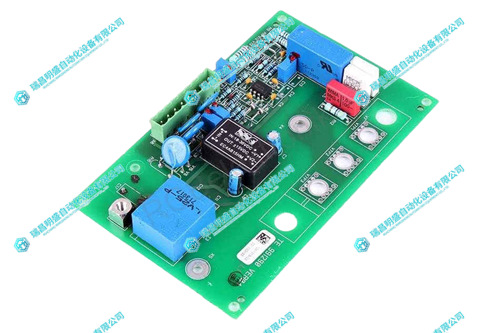

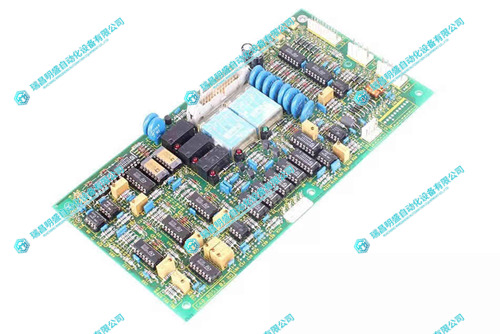

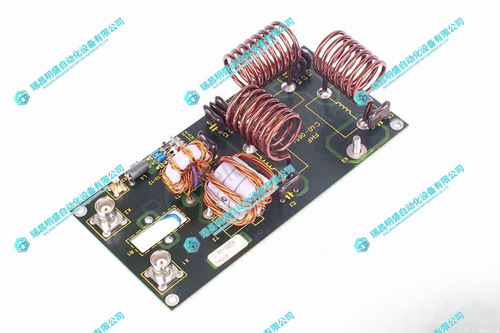

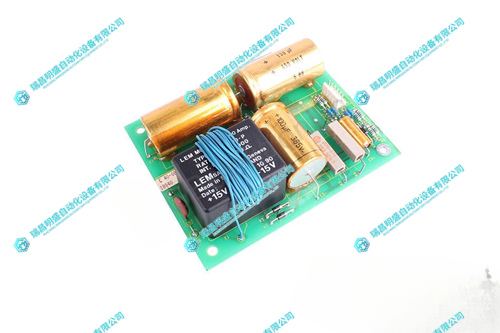

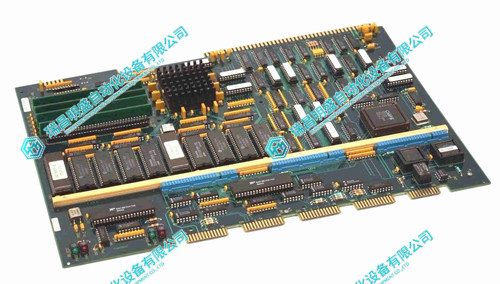

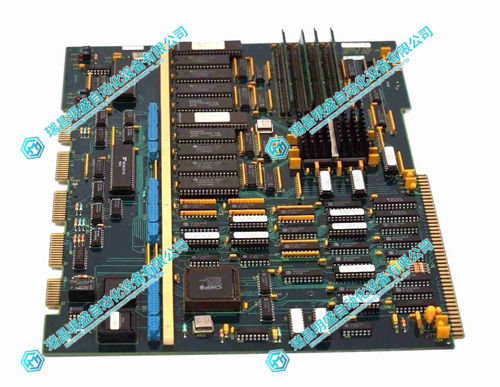

GIDDINGS & LEWIS 503-19515-20执行控制板

1.产 品 资 料 介 绍:

GIDDINGS & LEWIS 503-19515-20 执行控制板详解

一、核心功能:动作执行的 “精准指挥官”

二、技术特点:支撑精准控制的关键性能

英文资料:

GIDINGS&LEWIS 503-19515-20 Execution Control Board Detailed Explanation

1、 Core Function: Precise Commander for Action Execution

As the core control module of industrial automation and CNC machine tools, the GIDINGS&LEWIS 503-19515-20 execution control board undertakes the core responsibilities of "instruction decoding" and "action scheduling". It receives abstract instructions from the upper controller (such as position, speed, and action timing), converts them into specific control signals, and accurately drives servo drivers, stepper motors, hydraulic/pneumatic actuators, etc. It coordinates the action logic of various components of the equipment, ensuring that every step of the operation from simple start stop to complex multi axis linkage is precise and controllable. It is the "nerve center" that ensures the high-speed and high-precision operation of the equipment.

2、 Technical features: Key performance supporting precise control

Multi control capability: supports pulse output (controlling the displacement of stepper/servo motors), direction control (adjusting the motion direction of the actuator), and logic execution (coordinating the action timing of multiple devices), and can be adapted to different types of execution devices. For example, controlling the millimeter level displacement of the feed axis through pulse signals, switching the forward and reverse rotation of the spindle through directional signals, and synchronizing the tool changing action between the tool magazine and the spindle through logical signals.

Flexible interface adaptation: The input interface can seamlessly interface with the instruction signals of the main controller or logic module, and the output interface can drive multiple execution devices. It can directly connect servo drivers, stepper drivers, or expand the control range through relays, meeting the complex scenarios of single device to multi unit linkage.

Industrial grade signal compatibility: Compatible with industrial standard levels such as 24VDC, ensuring signal matching with upstream and downstream devices such as sensors and actuators, avoiding signal distortion caused by incompatible levels, and ensuring the accuracy of instruction transmission.

High speed response and synchronization: Equipped with high-speed pulse output capability (pulse frequency meets high dynamic requirements), response delay controlled in milliseconds, supporting multi axis synchronization control. In multi axis linkage machining of CNC machine tools, it can ensure that the time difference of each axis action is less than 0.1ms, achieving high-precision linear or circular interpolation.

Comprehensive protection mechanism: Integrated overload protection (preventing the actuator from exceeding the load limit), short circuit protection (cutting off abnormal circuits), overvoltage protection (resisting power fluctuations), and signal abnormality protection (identifying invalid instructions and giving alarms), multiple protections reduce equipment failures and minimize downtime losses.

Advantages of modular design: Adopting a plug-in card structure, it can be directly embedded into control cabinets or racks, and installation and replacement do not require dismantling the entire system. When expanding the production line or maintaining equipment, it is only necessary to plug and unplug modules to complete the operation, greatly reducing downtime.

Intuitive status monitoring: Real time display of the working status of each channel (running, faulty, standby, etc.) through LED indicator lights, allowing debugging personnel to quickly determine whether signal transmission is normal, and improving fault diagnosis efficiency by more than 50%.

2.产 品 展 示

3.其他产品

4.其他英文产品

IC3600SPRB1 Gas Turbine Contro

| PMA42Q-01100-00 | AMAT 0100-90221 | PFTL201CE |

| PMA42P-11100-00 | AMAT 0100-77034 | PFTL201DE |

| PMA42P-10100-00 | AMAT 0100-00042 | PFTL101BE-2.0KN 3BSE004214R1 2.0KN |

| PMA42P-01100-00 | AMAT 0100-00005 | PFTL101AER-1.0KN 3BSE023011R1 1.0KN |

| PMA42P-00100-00 | AMAT 0100-02706 | PFEA112-IP65 3BSE050091R65 |

| PMA42N-10100-00 | AMAT 0100-09153 | PFTL 101A-0.5 |

Contact: +86 15270269218