GIDDINGS & LEWIS M.1302.8416 伺服驱动器

1.产 品 资 料 介 绍:

GIDDINGS & LEWIS M.1302.8416 伺服驱动器详解

一、核心功能:单轴精密驱动的 “动力中枢”

二、技术特点:支撑高效驱动的关键性能

英文资料:

GIDINGS&LEWIS M.1302.8416 servo drive detailed explanation

1、 Core function: The "power center" of single axis precision drive

GIDINGS&LEWIS M.1302.8416 servo drive, as a high-performance single axis servo drive module, is the "power core" of CNC machine tools and industrial automation systems. It precisely adjusts the output current and voltage by receiving instructions from the upper control system, drives AC or brushless DC servo motors to complete preset actions, and relies on a closed-loop control mechanism to correct position, speed, and torque deviations in real time based on feedback signals, ensuring that the actuator maintains high accuracy during high-speed operation. It is a key hub connecting control instructions with actual actions.

2、 Technical features: Key performance supporting efficient driving

Single axis focused control: designed specifically for single axis drive, with highly focused control logic to avoid multi axis interference issues. In precision machining scenarios, the fluctuation of motor speed can be controlled within ± 0.05% to ensure the stability of cutting, drilling and other actions.

Wide voltage adaptability: Supports three-phase AC 220V/380V/460V industrial power supply, can adapt to ± 15% voltage fluctuations, and can operate stably in complex power grid environments without the need for additional voltage stabilizing equipment, reducing system integration costs.

Medium to high power output: Suitable for medium to high power servo motors (typical power range 3kW-20kW), with an output current stability of 0.3%, it can meet diverse needs from CNC machine tool spindle drive to industrial robot joint power output.

Multi mode flexible switching:

Position control: Achieve positioning accuracy of ± 0.0005mm level through pulse commands, suitable for cavity forming in precision mold processing;

Speed control: Supports wide speed range adjustment from 0-4000rpm, with a speed accuracy of ± 0.01%, suitable for constant speed paper feeding control of printing machines;

Torque control: Output torque error ≤ 1.5%, can be used for constant tension winding process of textile machinery.

High compatibility feedback: compatible with incremental encoders (such as 2048 lines), high-resolution parsers and other feedback devices, with a feedback signal sampling frequency of up to 2MHz, real-time capture of motor operating status, providing high-frequency data support for closed-loop control.

High speed communication interaction: High speed communication protocol (such as Profinet) is used with the G&L controller and upper system, with a data transmission delay of ≤ 0.5ms, to meet real-time command response in high dynamic scenarios, such as dynamic tension adjustment of high-speed packaging machines.

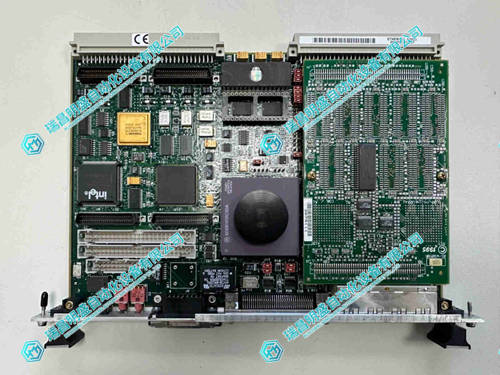

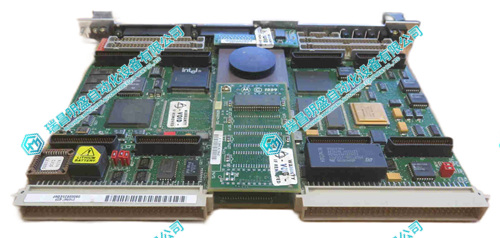

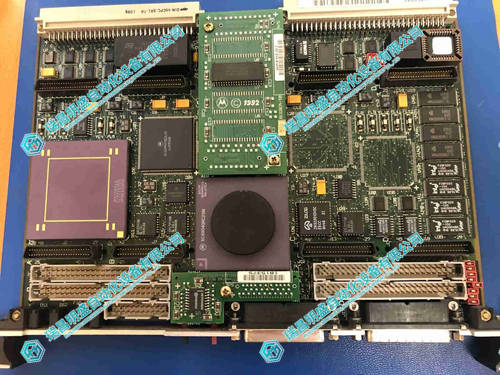

2.产 品 展 示

3.其他产品

4.其他英文产品

IC3600SPRB1 Gas Turbine Contro

ABB UN0807C-P Programmable Controller

| PMA24D-10100-00 | AMAT 0100-09081 | PFTL 101AER-2.0KN |

| PMA24D-00100-00 | AMAT 0100-20091 | PFTL 301E-0.2 |

| PMA24C-11100-00 | AMAT 0100-20321 | PFTL 101AE-1.0KN |

| PMA24C-10100-00 | AMAT 0100-20054 | PFTC 101X |

| PMA24C-00100-00 | AMAT 0100-20060 | PFEA113-65 3BSE050092R65 |

| PMA240-1150B-02 | AMAT 0100-00127 | PFTL101A-0.5KN 3BSE004166R1 |

| PMA23V-10100-00 | AMAT 0100-00177 | PFEA113 |

Contact: +86 15270269218