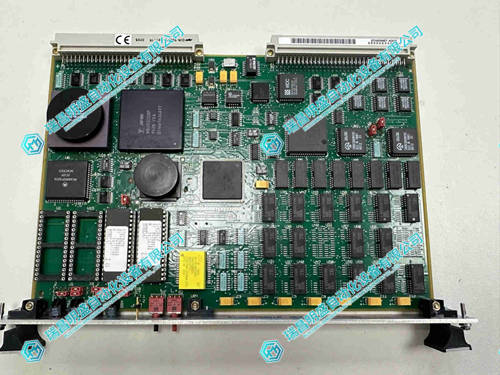

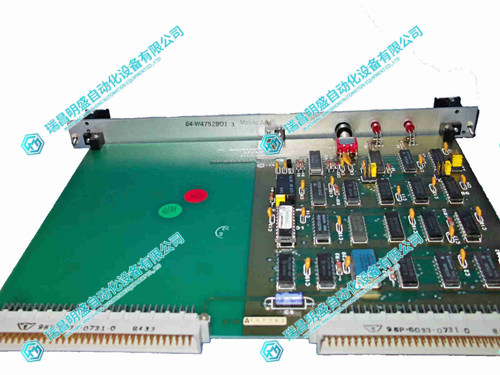

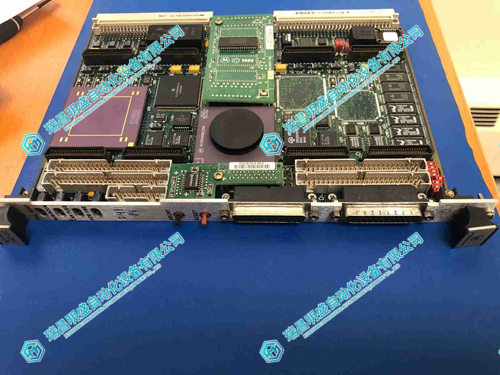

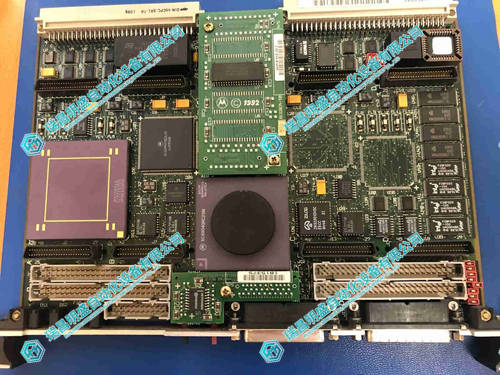

Motorola MVME162-02 工控控制卡件

1.产 品 资 料 介 绍:

Motorola MVME162-02 VMEbus 工业控制卡件深度解析

一、核心技术特性:适配工业场景的硬实力

1. 处理器与运算能力:平衡性能与稳定性

2. 存储配置:兼顾容量与数据安全

Motorola MVME162-02 工控控制卡件 英文资料:

Deep Analysis of Motorola MVME162-02 VMEbus Industrial Control Card

The Motorola MVME162-02 is an early classic model of the MVME162 series, a VMEbus industrial control card based on the MC68030/MC68040 processor architecture, essentially a highly integrated embedded single board computer (SBC). Its core value lies in "compact integration+industrial grade reliability+flexible expansion" - by integrating processors, memory, multiple types of I/O, and VME bus control functions, it can operate as an independent control unit or integrate into distributed systems to undertake core computing. It is an "old but critical" embedded control component in industrial automation, power, transportation and other fields, and still plays a role in a large number of legacy systems (legacy systems) today.

1、 Core technical feature: Hard power adapted to industrial scenarios

1. Processor and computing power: Balancing performance and stability

Flexible configuration of core chips:

The basic version is equipped with MC68030 CPU (25 MHz), 32-bit address/data bus, integrated 256B instruction cache+256B data cache, supports virtual memory management (MMU), and can meet basic tasks such as industrial logic control and data acquisition;

The high-end version can be upgraded to MC68LC040/MC68040 (33 MHz), with a cache capacity increased to 4KB (instructions+data). The computational efficiency is 1.5-2 times higher than 68030, and an optional MC68882 floating-point coprocessor is available to enhance the processing speed of floating-point intensive tasks such as power parameter calculation and radar signal preprocessing, avoiding performance loss caused by software simulation of floating-point.

Real time guarantee:

Supports multitasking real-time operating systems (RTOS), with interrupt response latency as low as microseconds (<10 μ s), and can prioritize handling high emergency events (such as device failure alarms and sensor overload protection), meeting the core requirements of industrial control's "millisecond level response".

2. Storage configuration: Balancing capacity and data security

DRAM memory: standard 4MB, expandable up to 16MB, supports parity check (some versions), ensures the accuracy of temporary data read and write during multitasking, and avoids control logic exceptions caused by memory errors (such as production line misoperation and power dispatch instruction errors);

Fixed storage: 256KB-2MB EPROM/Flash is used to store boot programs (such as Bootloader), operating system kernels, and basic drivers. Programs are not lost after power failure, and the system supports automatic startup when powered on, reducing manual intervention;

NVRAM and RTC: NVRAM with battery backup (typical capacity 8KB-32KB) can permanently store system parameters (such as control thresholds, device addresses), and is paired with a real-time clock (RTC) to record event timestamps for easy fault tracing (such as substation trip time, production line abnormal time).

Motorola MVME162-02 工控控制卡件 产 品 展 示

产品视频

3.其他产品

Rexroth RD52.1-7N-022-L-V1-FW伺服驱动器

WOODWARD 8200-1310逻辑控制器模块

AO2020 CALDOS25气体分析器

4.其他英文产品

07KR31 FPR36000227R1202-S Control module

3BSE030220R1 CI854AK01 Communication module

ABB AV94a HESG440940R11 Ladder logic module

| 6415-001-N-N-K | 6DD1681-0AJ2 | TRICONEX 3701 |

| 6415-001-N-H-K | 6DD1681-0AJ1 | TRICONEX 3703E |

| 6415-001-G-N-K | 6DD1681-0AJ0 | TRICONEX 3604E |

| 6415-001-C-N-N | 6DD1681-0AH2 | TRICONEX 3636R |

| 6415-001-C-N-K | 6DD1681-0AH1 | TRICONEX 3501E |

| 6415-001-C-M-K | 6DD1681-0AG2 | TRICONEX 3601E |

| 6415-001-C-H-K | 6DD1681-0AF4 | TRICONEX 3805H |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218