GIDDINGS & LEWIS SMP400控制器模块

1.产 品 资 料 介 绍:

GIDDINGS & LEWIS SMP400 控制器模块详解

一、核心功能:自动化系统的 “中央大脑”

二、技术特点:支撑复杂控制的关键性能

英文资料:

GIDINGS&LEWIS SMP400 Controller Module Detailed Explanation

1、 Core Function: The 'Central Brain' of Automation Systems

The GIDINGS&LEWIS SMP400 controller module, as the core processing unit of high-performance CNC systems, is the "nerve center" of machine tools and automation equipment. It receives real-time signals from input modules, sensors, and operation terminals, processes them at high speed to generate precise control instructions, coordinates the actions of external devices such as servo drives and actuators, and achieves automatic execution of multi axis linkage, process logic, and complex processes. Its core value lies in converting dispersed device signals into collaborative action instructions, which is the core hub to ensure high-speed and high-precision operation of the system.

2、 Technical features: Key performance supporting complex control

Powerful processing capability: Equipped with a high-speed digital signal processor (DSP), it can simultaneously handle multi axis motion control algorithms (such as interpolation and trajectory planning) and logical control tasks. In a five axis CNC machine tool, the tool path of the spatial surface can be calculated in real time to ensure that the motion error of each axis is controlled at the micrometer level.

Multi communication compatibility: Supports industrial standard buses (such as PROFINET, EtherCAT) and G&L dedicated control interfaces, which can be used with servo drives PLC、 Seamless integration of human-machine interface and other devices. In an automated production line, the actions of dozens of workstations can be synchronized through a bus, with a communication delay of ≤ 1ms.

Rich I/O management: It can manage the input and output of multiple digital signals (such as switch signals, limit signals) and analog signals (such as temperature and pressure signals), and adapt to various peripherals such as sensors and solenoid valves. For example, in a packaging machine, 16 material detection signals can be collected simultaneously and 8 actuator control signals can be output.

Large capacity program storage: Built in high-speed flash memory and RAM, capable of storing tens of thousands of lines of processing programs, process parameters, and logic instructions. In mass production, it supports calling processing programs for different products with a switching time of ≤ 0.5 seconds, meeting the requirements of flexible manufacturing.

Flexible scalability: Through modular interfaces and collaborative work with external devices such as servo drives, execution control boards, input analysis modules, etc., it can be extended from a single machine tool to the entire line automation system. For example, in the automotive welding production line, it is possible to expand and control 20 welding robots and 10 conveyor lines.

High real-time response: The instruction processing cycle can reach milliseconds, and the feed rate can be adjusted in real-time in high-speed machining scenarios (such as when the spindle is running at 10000rpm) to avoid vibration and error accumulation. In robot trajectory tracking, the motion command can be corrected every 1ms to ensure a repeat positioning accuracy of ± 0.02mm.

Comprehensive protection mechanism: Integrated overload, short circuit, overvoltage, and signal abnormality protection logic. When equipment faults are detected (such as motor overcurrent or sensor disconnection), emergency stop commands can be triggered within 10ms and fault codes can be recorded for quick troubleshooting.

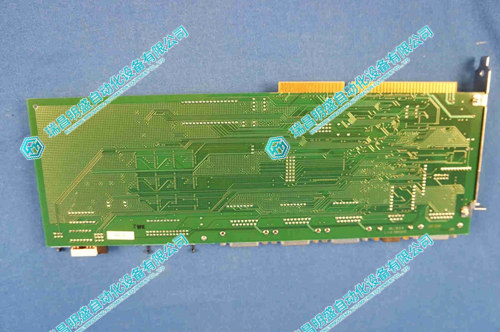

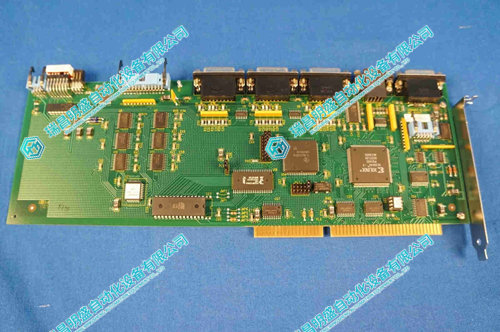

2.产 品 展 示

3.其他产品

4.其他英文产品

ABB UN0807C-P Programmable Controller

HE700GEN200 Network Interface Module

| PMA22B-10100-00 | AMAT 0100-14003 | PFTL101A-0.5 3BSE004160R1 0.5 |

| PMA22B-01100-22 | AMAT 0100-35279 | PFTL101A-1.0KN 3BSE004166R1 |

| PMA22B-01100-00 | AMAT 0100-77043 | PFTL 101AER-1.0KN |

| PMA22B-00100-00 | AMAT 0100-00060 | PFTL-101A 3BSE008508R1 |

| PMA21B-10100-00 | AMAT 0100-00059 | PFEA112-65 |

Contact: +86 15270269218