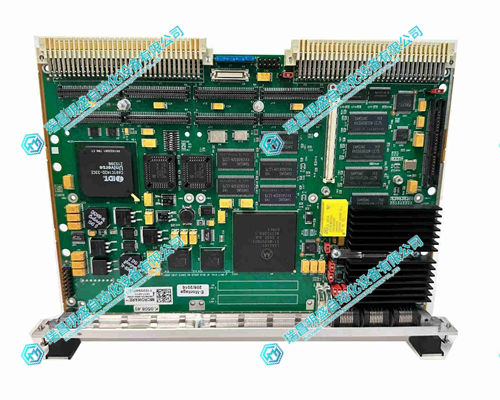

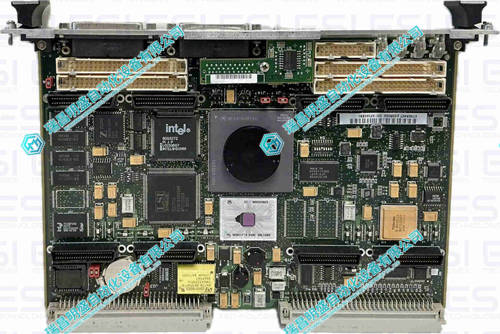

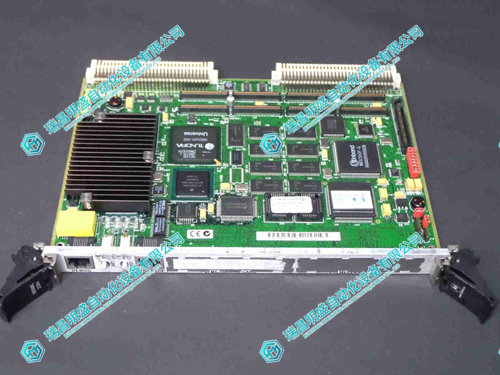

GIDDINGS & LEWIS 502-03876-02控制器模块

1.产 品 资 料 介 绍:

GIDDINGS & LEWIS 401-34438-00 无刷伺服电机详解

一、核心功能:高精度运动的 “动力执行单元”

二、技术特点:支撑高效运动的关键性能

英文资料:

GIDINGS&LEWIS 401-34438-00 Brushless Servo Motor Detailed Explanation

1、 Core function: "Power execution unit" for high-precision motion

GIDINGS&LEWIS 401-34438-00 brushless servo motor, as an industrial grade high-performance execution component, has become the "power core" of CNC machine tools and automation equipment with its brushless structural design and precise control capabilities. It converts the electrical signal of the servo drive into mechanical motion, corrects the action error in real-time through closed-loop feedback, maintains micrometer level positioning accuracy during high-speed operation, and relies on brushless technology to reduce wear and ensure long-term stable operation. It is a key execution unit that connects control instructions with actual actions.

2、 Technical features: Key performance supporting efficient movement

Advantages of brushless structure: using electronic commutation instead of traditional electric brushes, completely eliminating mechanical wear and spark interference, and extending the service life to more than 20000 hours (5 times that of brushed motors). In a continuously running automated production line, it can reduce 90% of motor maintenance times and minimize downtime losses.

Medium power precise output: The rated power covers medium power levels (typical 1.5kW-15kW), which can stably drive multi axis machine tool feed systems or robot joints. The output torque fluctuation is ≤ 2%, ensuring the uniformity of cutting, assembly and other actions.

Wide voltage adaptation: Compatible with industrial standard voltages such as 220V/380V AC, adapts to ± 10% voltage fluctuations through internal voltage regulation circuits, and can maintain stable speed (fluctuation ≤ 0.5%) in workshop environments with unstable power.

High speed response: The rated speed design supports high-speed operation (typical 3000rpm to 6000rpm), and with the help of servo drives, it can achieve acceleration time of 0-6000rpm ≤ 0.5s, meeting the dynamic requirements of high-speed cutting, fast sorting and other scenarios.

Multi mode closed-loop control:

Position control: Achieve ± 0.001mm positioning accuracy through encoder feedback, suitable for hole position control of precision drilling machines;

Speed control: Speed control accuracy ± 0.1%, suitable for constant speed paper feeding of printing machines;

Torque control: Output torque error ≤ 3%, can be used for constant tension winding of textile machinery.

High resolution feedback: Built in incremental encoder (typical 2048 line) or parser, feedback signal frequency up to 1MHz, real-time transmission of position and velocity information to the driver, providing high-frequency data support for closed-loop control.

Flexible cooling design: The air-cooled version is equipped with a low-noise fan (noise ≤ 65dB), while the natural cooling version uses high-efficiency heat dissipation fins, which can operate continuously at full load at an ambient temperature of 40 ℃, with temperature rise controlled within 70K.

Standardized mechanical interface: using standard flanges (such as ISO 9409-1) and shaft design, compatible with mainstream couplings and load connection methods, installation and replacement do not require modification of equipment mechanical structure, with strong adaptability.

2.产 品 展 示

3.其他产品

4.其他英文产品

Asea 2668-184-280 12 slot control board

HAAS 93-32-3550J Intelligent Driver

ABB CHBX01R 2VAA008575R1 redundant modul

| PC844-001-A | MC-GAIH83 | |

| PC843-XYZ-T | MC-GAIH22 | |

| PC843-XYZ-N | 6SC6500-0UC01 | MC-PDOX02 |

| PC843-XYZ-F | 6SC6100-0GA00 | NTDI01 |

| PC843-XYZ-A | 6SC6120-0FE00 | NKTT01-3 |

| PC843-001-T | HESG447433R0001 70BV05A-ES | |

| PC843-001-N | 6SC6100-0GA11 | HESG446933R0002 70AB02B-E |

Contact: +86 15270269218