GIDDINGS & LEWIS 502-03B53-02遥控 I/O 驱动模块

1.产 品 资 料 介 绍:

GIDDINGS & LEWIS 502-03B53-02 遥控 I/O 驱动模块应用领域及价值解析

一、核心应用领域

1. 远程数控机床控制领域

2. 分布式自动化生产线领域

3. 工业机器人系统领域

4. 包装与印刷设备领域

英文资料:

Application Fields and Value Analysis of GIDINGS&LEWIS 502-03B53-02 Remote Control I/O Driver Module

1、 Core application areas

1. Remote CNC machine tool control field

This module communicates in real-time with the machine tool controller through an industrial bus interface (such as EtherCAT or Profinet) to achieve remote and precise control of spindle speed, feed axis displacement, and tool magazine tool changing actions. In the aerospace parts processing scenario, the spindle motor can be driven by remote commands to achieve high-speed cutting at 12000rpm, while synchronously controlling the feed axis to complete complex surface milling with an accuracy of ± 0.005mm. Combined with sensor feedback, the module can monitor the tool wear status in real time and trigger the automatic tool change process, with a tool change time of ≤ 1.5 seconds, significantly improving machining continuity and efficiency.

2. Distributed automation production line field

In the distributed control system of the automobile assembly workshop, the module synchronously controls the mechanical arm grasping, bolt tightening machine torque adjustment, and conveyor line start stop of 30+workstations through multi-channel digital output. Its millisecond level response capability (typical value ≤ 10ms) ensures that the time difference between each workstation action is ≤ 0.3 seconds, and the production line cycle efficiency is increased by 25%. Modular design supports flexible expansion, allowing for easy addition of detection stations or adjustment of process paths, reducing system downtime and modification time.

3. In the field of industrial robot systems

As the core interface for joint control of collaborative robots, the module drives servo motors through analog output to achieve a repeat positioning accuracy of ± 0.02mm. In the assembly scenario of 3C products, with real-time feedback from the visual system, the module can dynamically adjust the posture of the end effector to complete chip mounting with a gap of 0.1mm. Its distributed architecture supports multi robot collaborative operations. For example, in a lithium battery module assembly line, three robots synchronize the entire process of grasping, welding, and inspection through modules, resulting in a 40% increase in operational efficiency compared to a single machine.

4. Packaging and printing equipment field

In the high-speed food packaging machine, the module precisely controls the speed of the film feeding motor and the phase matching of the cutting blade through pulse signals, ensuring that the packaging size error is ≤ 0.8mm at a production rate of 400 packages per minute. Its analog output can dynamically adjust the heat sealing temperature, combined with temperature sensor feedback to form a closed-loop control, and the sealing qualification rate is increased from 95% to 99.7%. The remote monitoring function supports engineers to adjust parameters in real-time through the upper system, reducing on-site debugging time by more than 50%.

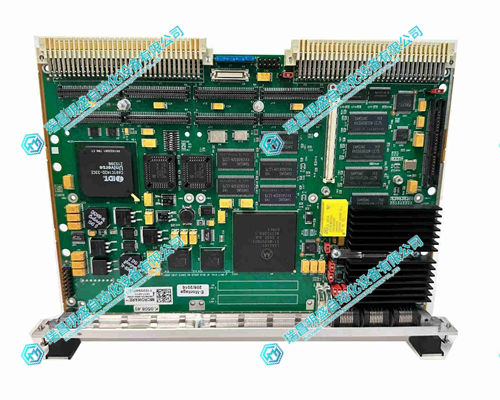

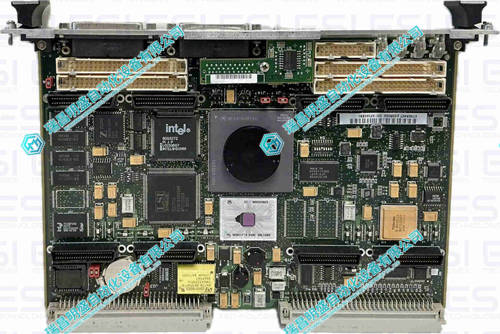

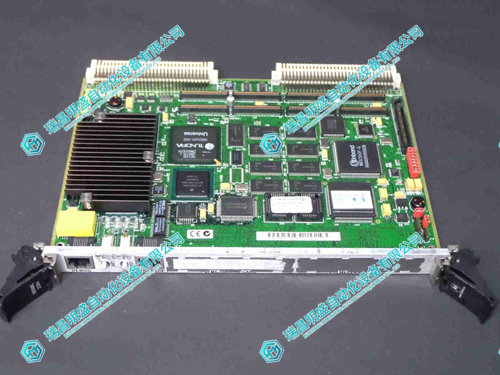

2.产 品 展 示

3.其他产品

4.其他英文产品

ABB CHBX01R 2VAA008575R1 redundant modul

Schneider 140CP43412A Controller Module

Schneider 140CPS11100 Analog Input Modul

| PC842-001-T | Gespac CI0-1B | PHARPSCH100000 |

| PC842-001-N | Gespac SI0-1E | HESG332181R0001 70BL02D-S |

| PC842-001-F | Gespac GESVIG-4VME | NTCL01 |

| PC842-001-A | 6SC6190-0FB00 | NTRO04 |

| PC834-XYZ-T | AMAT 0100-00070 | 57390001-7 D5001 SB5032 ABB |

Contact: +86 15270269218