GIDDINGS & LEWIS M.1301.6598伺服驱动器

1.产 品 资 料 介 绍:

GIDDINGS & LEWIS M.1301.6598 伺服驱动器详解

一、核心功能:高精度运动的 “驱动中枢”

二、核心产品特点:支撑高要求场景的关键性能

精确闭环控制体系

高速动态响应能力

多模式灵活控制

英文资料:

GIDINGS&LEWIS M.1301.6598 servo drive detailed explanation

1、 Core function: The "driving center" for high-precision movement

GIDINGS&LEWIS M.1301.6598 servo drive, as a single axis drive module, is the "power regulation core" of high-precision industrial control and CNC machine tools. It receives instructions from the upper controller and combines real-time feedback signals to achieve closed-loop precise control of the position, speed, and torque of the servo motor, converting electrical signals into stable mechanical motion outputs. In complex scenarios such as high-speed cutting and multi axis linkage, its core value lies in balancing dynamic response speed and control accuracy, ensuring that the actuator maintains micrometer level stability in high-frequency actions, and is the key execution unit connecting instructions and actions in multi axis control systems.

2、 Core product features: Key performance to support high demand scenarios

Precise closed-loop control system

Equipped with a high-resolution feedback interface (compatible with encoders and parsers), the feedback signal sampling frequency reaches 1MHz, which can capture real-time changes in motor rotor position. By using advanced PID+feedforward control algorithms, the deviation between instructions and actual actions is dynamically corrected to ensure positioning accuracy of ≤± 0.001mm and repeated positioning accuracy of ≤± 0.0005mm. For example, in precision grinding, the roundness error of the workpiece can be controlled within 2 μ m, meeting the process requirements of high-precision parts.

High speed dynamic response capability

The current loop bandwidth is increased to 2.5kHz, the speed loop response time is ≤ 3ms, and the acceleration time of the motor from 0 to 4000rpm is ≤ 0.3s, with no overshoot during the deceleration process. In multi axis linkage equipment (such as five axis machining centers), complex trajectory instructions can be accurately followed to avoid contour errors caused by response lag, ensuring that the surface roughness Ra of surface machining is ≤ 0.8 μ m.

Multi mode flexible control

Position control: Absolute/relative position control is achieved through pulse commands or bus signals, suitable for scenarios such as drilling and boring that require precise positioning;

Speed control: supports analog quantity, pulse frequency or bus command to adjust the speed, with a speed control accuracy of ± 0.02%, suitable for constant speed cutting, conveying and other working conditions;

Torque control: Torque output regulation is achieved through current closed-loop, with a torque control accuracy of ≤ 2%. It can be used in scenarios such as tension control and pressure assembly.

The three modes can be seamlessly switched through parameters or instructions to meet diverse process requirements.

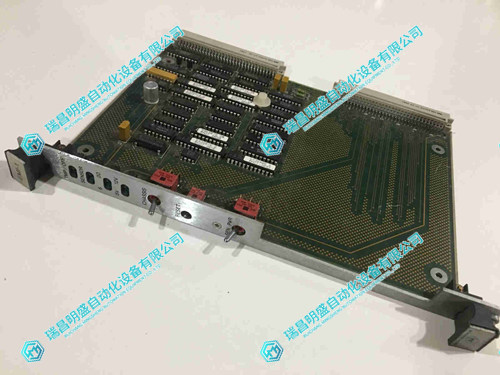

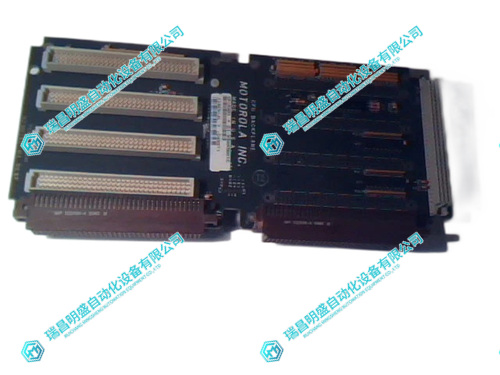

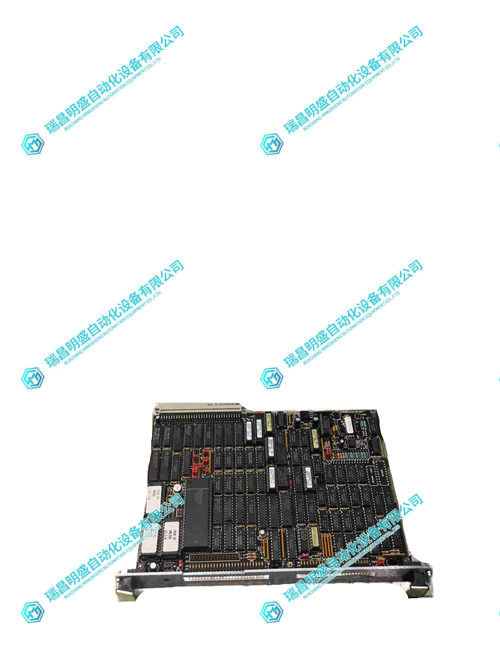

2.产 品 展 示

3.其他产品

REXROTH PPC-R22.1N-T-NN-P1-NN-FW 伺服控制器

4.其他英文产品

KOLLMORGEN 6SM37M-6000 servo motor

A-B 1794-IRT8XT Relay Output Module

| LB3-48E-Q-01 | AMAT 0100-90135 | 57120001-P DSAI130 |

| Lam Research 853-230312-008 | AMAT 0100-90971 | HESG447220R0004 70EB02C-ES |

| Lam Research 810-048219-019 | AMAT 0100-90967 | HESG223147R0001 70VA01B-E |

| Lam Research 605-230312-008 | AMAT 0100-09304 | NTMP01 |

| Lam Research 605-064676-005 | AMAT 0100-76030 | HESG332143R0001 70EB10A-E |

| K43HRLM-LNK-NS-01 | AMAT 0100-40037 | HESG447260R0002 70BA01C-S |

Contact: +86 15270269218