GIDDINGS & LEWIS 573-26404-20输入输出模块

1.产 品 资 料 介 绍:

GIDDINGS & LEWIS 573-26404-20 输入输出模块详解

一、产品概况

二、关键技术参数(典型特性)

三、核心应用场景

英文资料:

GIDINGS&LEWIS 573-26404-20 Input/Output Module Detailed Explanation

1、 Product Overview

GIDINGS&LEWIS 573-26404-20 input/output module is a key signal interface component in the field of industrial automation and numerical control systems. Its core responsibility is to collect, summarize, distribute, and transmit various internal and external signals of the system. This module relies on multiple input/output channels to build a bridge for data exchange and control signal transmission between devices. Whether it is the precise operation of machine tool control systems or the efficient collaboration of automated production lines, it plays an indispensable role and is one of the core components to ensure the stable operation of industrial equipment.

2、 Key technical parameters (typical characteristics)

Module model: 573-26404-20

Functional positioning: Focused on input/output interface modules for signal interaction, adapted to the signal processing needs of industrial automation and CNC systems

Input port configuration: Supports synchronous acquisition of multiple digital and analog signals, and can flexibly respond to signal access from different types of sensors and detection devices

Output port performance: able to stably output driving signals, providing reliable signal support for relays, actuators, and other peripheral control devices, ensuring precise action of executing components

Interface compatibility design: Perfectly compatible with GIDINGS&LEWIS control system dedicated buses, ensuring efficient data transmission between modules and system bodies, and avoiding interface adaptation issues

Signal transmission guarantee: adopting professional anti-interference design, effectively resisting electromagnetic interference in industrial sites through shielding, filtering and other technical means, ensuring the stability and accuracy of signal transmission

Electrical safety protection: Built in short-circuit protection, overcurrent protection, and overvoltage protection mechanisms, quickly cutting off risks in case of circuit abnormalities, protecting modules and associated equipment from damage

Installation form: Adopting a cabinet plug-in installation structure, there is no need for complex disassembly process, which is convenient for module replacement, maintenance and system expansion in the later stage

3、 Core application scenarios

CNC machine tool control system: responsible for inputting and collecting tool status monitoring signals, servo drive feedback signals, workpiece fixture clamping/releasing signals, etc. during the operation of CNC machine tools, and outputting control instructions to achieve precise control of key components of the machine tool, ensuring machining accuracy and smooth processes

Automated production line: As the "signal hub" of the production line, it connects sensors (such as position sensors and temperature sensors) with the central control unit, collects real-time status signals during the production process, and distributes control instructions from the central unit to executing agencies (such as cylinders and motors) to achieve automated collaborative operation of the production line

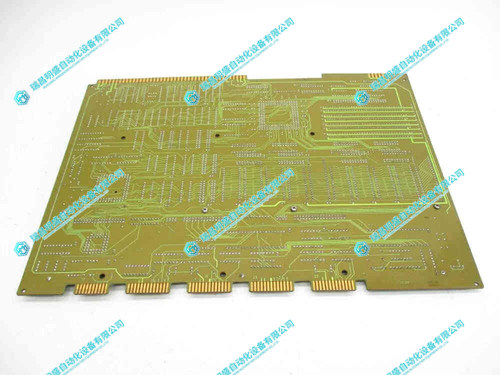

2.产 品 展 示

3.其他产品

4.其他英文产品

CI871AK01 3BSE092693R1 interface module

VE5010 Logic Controller Module

KJ3222X1-BA1 Analog Input Module

| IC3600SFUA1C | 6DD1682-0BC3 | IC3600SSVD1 |

| IC3600SFUA1 | 6DD1682-0BC0 | IC3600SSVB1B |

| IC3600SFPB1B1C | 6DD1683-0CC0 | IC3600SSVB1 |

| IC3600SFPB1B | 6DD1683-0BE5 | IC3600SSVA1F1C |

| IC3600SFPB1 | 6SC6504-0AF01 | IC3600SSVA1 |

| IC3600SFKK1 | 531X300CCHALM3 | IC3600SSLD1H1D |

| IC3600SFKD1C | IC3600SSLD1F1B | |

| IC3600SFKD1 | 531X300CCHAJM2 | IC3600SSLD1E |

Contact: +86 15270269218