GIDINGS&LEWIS 501-04454-00机器控制模块

1.产 品 资 料 介 绍:

GIDDINGS & LEWIS 501-04454-00 机器控制模块产品特点解析

一、高精度控制:筑牢精密制造核心基础

二、多功能接口:打通多设备协同通信链路

英文资料:

GIDINGS&LEWIS 501-04454-00 Machine Control Module Product Features Analysis

GIDDINGS&LEWIS 501-04454-00 machine control module is a core component in the field of industrial automation and machine tool control. With seven core product features, it accurately adapts to the control needs of complex industrial scenarios, providing strong support for stable operation and efficient production of equipment. The specific characteristics are analyzed as follows:

1、 High precision control: Building a solid foundation for precision manufacturing core

This module has excellent high-precision control capabilities and is a key guarantee for precision machining scenarios. In CNC machine tools and precision machining equipment, micrometer level precision control can be achieved for equipment axis motion (such as feed displacement of X/Y/Z axes and angle adjustment of rotation axes), for example, controlling the tool feed error of milling machine tools to be less than 0.001mm, ensuring the dimensional accuracy of part machining; At the same time, it can accurately locate the tool position (such as precise calculation of tool radius compensation and length compensation) and workpiece operation (such as workpiece clamping force control and rotation positioning), avoiding machining scrap caused by control deviation. In addition, relying on optimized control algorithms, the module can achieve high-speed and highly repetitive action response - in automated assembly lines, the deviation of the action of controlling the robotic arm to repeatedly grasp parts can be controlled within 0.1mm, meeting the dual requirements of "high-speed operation" and "precise operation" for precision manufacturing such as automotive parts and aerospace parts.

2、 Multi functional interface: Connect the collaborative communication links of multiple devices

The module is equipped with rich multifunctional interfaces, providing convenience for the connection and integration of multiple devices in industrial systems. On the one hand, it provides multi-channel digital/analog input/output interfaces, which can directly interface with servo motors (driving equipment movement, such as machine tool spindles, conveyor belt motors), various sensors (such as temperature sensors, pressure sensors, position sensors, real-time collection of on-site data), and actuators (such as cylinders, solenoid valves, regulating valves, executing control instructions), without the need for additional signal conversion modules, simplifying equipment wiring and reducing system complexity; On the other hand, it supports standard industrial communication protocols such as Profibus, Modbus, Ethernet, etc., and can seamlessly communicate with CNC controllers (such as the core control unit of CNC machine tools), PLCs (programmable logic controllers), and upper computer systems (such as industrial monitoring computers and production management platforms). It can receive processing programs and production scheduling instructions issued by the upper system, as well as upload equipment operating parameters and fault alarm information, achieving full link data interoperability of "sensor controller actuator upper system" and adapting to multi device collaborative automation production lines and complex machine tool control systems.

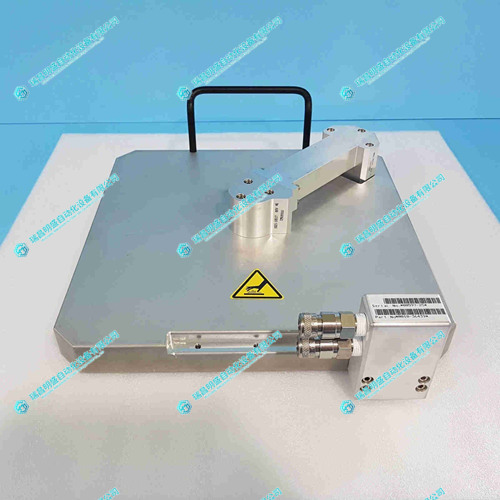

2.产 品 展 示

3.其他产品

KOLLMORGEN CP310250 PRD-P310250Z-55 伺服驱动器

4.其他英文产品

HONEYWELL 05704-A-0146 Digital

1TGE120011R1111 Controller Module

PROSOFT MVI46-MCM communicatio

| IC3600LFAA1 | 531X140CCHANM2 | IC3600AOAA2B |

| IC3600LDEG1B | 531X140CCHAMM2 | IC3600AOAA2 |

| IC3600LDEG1 | 531X139APMAYG2 | IC3600AOAA1D |

| IC3600LDDB1 | 531X139APMAXG2 | IC3600AOAA1A |

| IC3600LDDA1 | 531X139APMATG2 | IC3600AOAA1 |

| IC3600LDCA1 | 531X139APMASM7 | IC3600AOA |

| IC3600LCDA1B | 531X139APMASG2 | IC3600AMLG1A |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218