GIDINGS&LEWIS 501-04304-00中央服务模块

1.产 品 资 料 介 绍:

GIDDINGS & LEWIS 501-04304-00 中央服务模块解析

一、产品概述

二、技术参数(典型特性)

英文资料:

GIDINGS&LEWIS 501-04304-00 Central Service Module Analysis

1、 Product Overview

The GIDINGS&LEWIS 501-04304-00 central service module is the "core coordination hub" for industrial automation systems and CNC machine tools, responsible for the key functions of global system control and module collaborative management. It is not only responsible for coordinating the running rhythm of various components such as CPU modules, I/O modules, and servo drive modules within the system, but also needs to handle central control logic (such as priority scheduling for multi module linkage), manage the communication links and data streams of the entire system (ensuring orderly and conflict free data transmission), and issue precise instructions to execution units (such as servo motors and actuators) to support. As the "central nervous system" of the system, this module ensures seamless coordination between control modules, input/output devices, and servo systems through efficient resource allocation and collaborative control, avoiding operational failures caused by asynchronous responses between modules. It is the core guarantee for stable and efficient operation of complex industrial control systems.

2、 Technical parameters (typical characteristics)

Product model: 501-04304-00

Functional positioning: Industrial grade Central Service Module, leading system module collaboration and global control management

Processing capability: Equipped with high-performance industrial processors, it has fast computing speed and strong multitasking capabilities. It can simultaneously support real-time control logic execution (such as multi axis linkage timing scheduling) and system management (such as module status monitoring and resource allocation), avoiding collaborative delays caused by insufficient computing power

Interface configuration: Equipped with multi-channel dedicated communication interfaces, it can directly establish stable connections with CPU modules (receiving operation instructions), I/O modules (interacting with on-site data), and servo drive modules (issuing motion control instructions). The interface protocol is compatible with GIDINGS&LEWIS modules of the same series, and data interoperability can be achieved without additional debugging

Data management capability: Supports real-time monitoring of the entire system status (such as module operating parameters, equipment load conditions), fault diagnosis (automatically identifying communication interruptions, module abnormalities, and recording logs), and parameter management (storing/calling system configuration parameters, process parameters), making it easy for operation and maintenance personnel to grasp the system status in real time and quickly locate faults

Protection function: Integrated with multiple electrical protection mechanisms, including overcurrent protection (preventing module to module current overload from burning communication interfaces), overvoltage protection (resisting internal circuit fluctuations), overheating protection (triggering derating or alarm when temperature is too high), and short circuit protection (quickly cutting off the circuit when the circuit is short circuited), to ensure the safety of the module itself and related components

Installation method: adopting modular slot design, compatible with industrial standard cabinet rails, can be installed side by side with other control modules, and the wiring is neat; The module is easy to plug and unplug, and can be quickly replaced in case of failure, greatly reducing system downtime and maintenance time

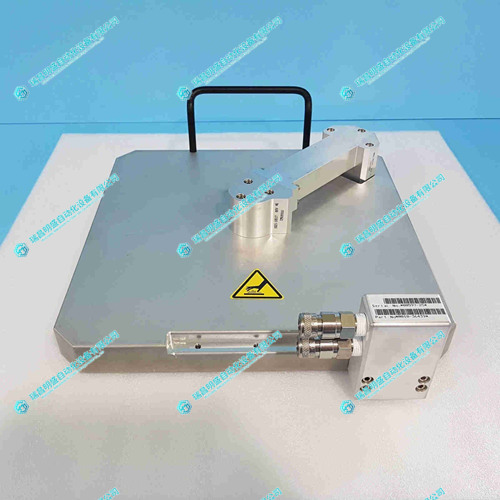

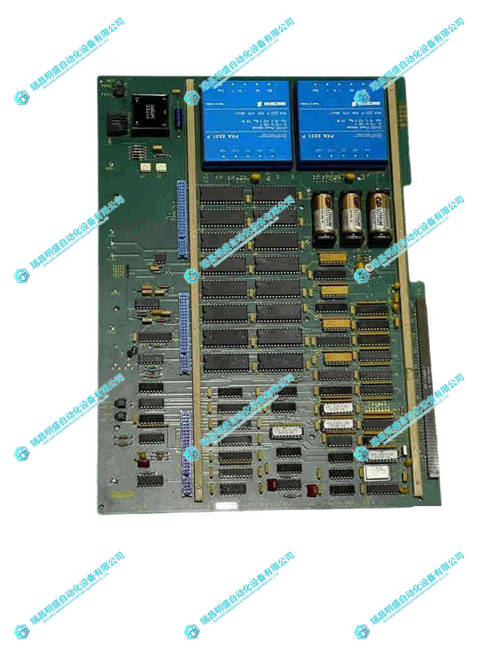

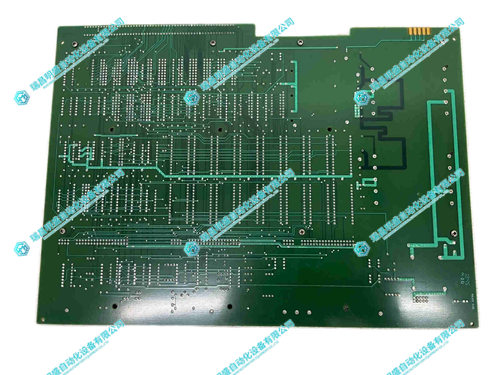

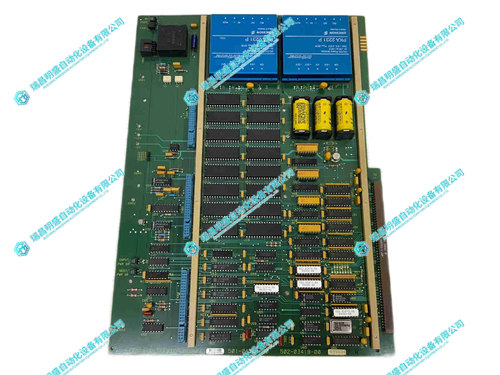

2.产 品 展 示

3.其他产品

4.其他英文产品

Emerson P144.R4 Intelligent I/O Board

ABB XVC768117 Field Input/Output Module

Eaton XV-440-10TVB-1-50 Touch Screen

| IC3600KVSA1B | 531X139APMALM7 | IC3600AIAD1C1D |

| IC3600KVSA1 | 531X139APMALG2 | IC3600AIAD1B |

| IC3600KRSV1B1B | 531X139APMAKM7 | IC3600AIAD1 |

| IC3600KRSV1A1A | 531X139APMAKG2 | IC3600AIAC1E |

| IC3600KRSU1A | 531X139APMAJG2 | IC3600AIAC1 |

| IC3600KRSU1 | 531X139APMAHG2 | IC3600AIAA1G1B |

| IC3600KRST1A | 531X139APMAGM1 | IC3600AFRB1B1B |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218