GIDINGS&LEWIS M.1302.1162 伺服电机

1.产 品 资 料 介 绍:

GIDDINGS & LEWIS M.1302.1162 伺服电机解析

一、产品概述

二、技术参数(典型特性)

英文资料:

GIDINGS&LEWIS M.1302.1162 servo motor analysis

1、 Product Overview

GIDINGS&LEWIS M.1302.1162 servo motor is a high-performance execution component designed specifically for CNC machine tools, automation equipment, and industrial robot systems, responsible for the core function of "instruction reception precision drive". It can accurately receive control signals issued by servo drives, and achieve high-speed and high-precision control of motor position, speed, and torque parameters through internally optimized electromagnetic structure and closed-loop control logic, ensuring the precise execution of tasks such as machining, cutting, and automated assembly. This motor is designed to meet the needs of industrial scenarios, with high reliability (reducing downtime due to faults), low maintainability (avoiding frequent maintenance), and strong environmental adaptability (resisting harsh working conditions). It has become a key bridge connecting the "control center" and "mechanical action" in industrial automation systems, providing core power support for stable and efficient operation of equipment.

2、 Technical parameters (typical characteristics)

Product model: M.1302.1162

Motor type: Industrial grade servo motor, suitable for high-precision and high dynamic response motion control scenarios

Control mode: Supports triple closed-loop control modes - closed-loop position control (with positioning accuracy up to micrometer level, meeting precision positioning requirements, such as machine tool feed axis positioning), closed-loop speed control (with small speed fluctuations, strong resistance to load disturbances, and suitable for stable spindle rotation), closed-loop torque control (with stable torque output, suitable for constant load scenarios, such as clamping devices). The three modes can be flexibly switched according to working conditions, covering various industrial control needs

Feedback device: Integrated high-precision absolute value encoder (or incremental encoder, depending on the configuration), high resolution (usually ≥ 17 bits), capable of real-time acquisition of motor rotor position and speed data, feedback to servo drive to form closed-loop regulation, effectively offsetting control errors caused by mechanical clearance and load fluctuations, ensuring driving accuracy

Rated power: The power specifications can be flexibly adapted according to the system configuration, covering the range of medium to high power (such as 0.75kW-15kW), which can meet the driving needs of small and medium-sized loads such as CNC machine tool feed axes and robot joints, as well as adapt to the power output of some equipment spindles, with strong compatibility

Dynamic performance: Adopting a low inertia rotor design and optimized winding structure, the motor has fast response speed for starting, accelerating, and braking (response time ≤ 5ms), can quickly follow changes in control signals, adapt to high-frequency start stop, fast positioning and other scenarios (such as high-speed sorting actions in automated production lines), and maintain low noise (≤ 70dB) and low heating characteristics even during high-speed operation (rated speed can reach 3000r/min or above)

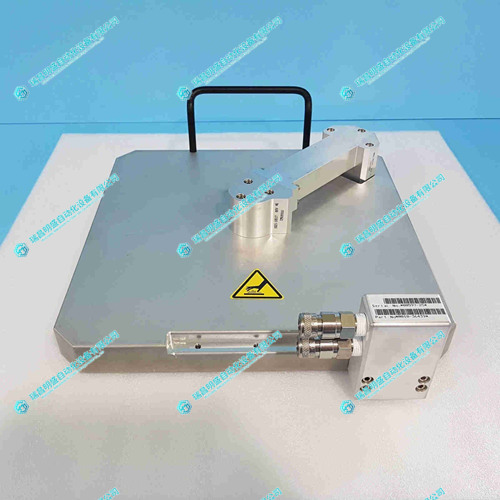

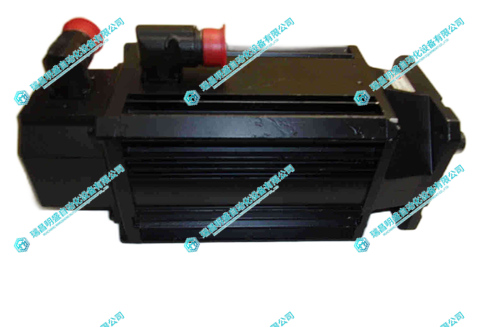

2.产 品 展 示

3.其他产品

4.其他英文产品

IS400JPDHG1ABB IS410JPDHG1A Feedback Sen

ASEA DSQC100 connector backplane

| 850-EP5NNS5HNNAANGAPCCSENNBN | AMAT 0100-90243 | PFEA 112, IP 20 |

| 850-EP5NNS5HNNAANGAPCB2ESNBN | AMAT 0100-76290 | 21660559-H DSRA110 ABB |

| 850-EP5NNS5HNNAAFGAPFB3ECNAN | AMAT 0100-11025 | PFCL201CD/CE |

| 850-EP5NNS1HNNAAAGMSFB1ECNBN | CACR-SR1B-E | 57360001-DC DSMC120 ABB |

| 850-EP5NNG5HNNANNGSSFBSEWNBN | CACR-SR03BE12M-E | 5735099-BA DSIH71 ABB |

| 850-EP5NNG5HNNANNGSSFBSENNBN | SERVOSTAR-601 | 48980002-A DSSB120 ABB |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218