GIDINGS&LEWIS M.1301.0399以太网模块

1.产 品 资 料 介 绍:

GIDDINGS & LEWIS M.1301.0399 以太网模块产品应用领域

一、数控机床(CNC)系统

二、自动化生产线

三、工业监控与管理系统

英文资料:

GIDINGS&LEWIS M.1301.0399 Ethernet Module Product Application Fields

GIDINGS&LEWIS M.1301.0399 Ethernet module, as a key network communication unit in industrial automation systems, provides efficient network connection support for different industrial scenarios with stable Ethernet data transmission capabilities and multi device compatibility. Its specific application areas are as follows:

1、 Numerical Control Machine Tool (CNC) System

In the CNC system, this Ethernet module serves as the data exchange hub between the machine tool and the central control system. On the one hand, bidirectional data communication between CNC machine tools and workshop central control systems is achieved through Ethernet, supporting remote uploading and downloading of CNC machining programs - for example, engineers can write machining programs on the central control terminal and quickly transmit them to multiple CNC machine tools through modules, without the need for on-site debugging, greatly improving program deployment efficiency; On the other hand, real-time feedback of machine tool operating status data (such as spindle speed, tool wear, machining progress) is provided to the central control system, and remote monitoring function is also supported. Operation and maintenance personnel can view machine tool operating parameters in real-time in the central control room, detect abnormalities in a timely manner, and intervene. In addition, the module can integrate machine tool production data, provide data support for production scheduling optimization, significantly improve machine tool networking capabilities and overall production management efficiency, and adapt to precision parts batch processing scenarios.

2、 Automated production line

In automated production lines, modules are the bridge for data exchange and collaborative control among multiple devices. For key equipment such as industrial robotic arms, material conveying equipment (such as belt conveyors), and sorting systems in the production line, modules achieve high-speed data exchange between devices through Ethernet. For example, after the robotic arm completes part grasping, the module transmits a "grasping completion" signal in real time to the conveying equipment, triggering the start of the conveying equipment and accurately feeding to the next workstation; At the same time, it supports multi device collaborative logic to ensure the synchronization of the action timing of the robotic arm, conveying equipment, and sorting device, avoiding production delays caused by data transmission delays. In addition, the module can also upload the operational data of various equipment on the production line (such as production capacity and fault alarms) to the production line management system, helping management personnel to grasp the production progress in real time, improve the automation and informatization level of the production line, and adapt to batch production scenarios such as automotive parts and electronic components.

3、 Industrial Monitoring and Management System

In industrial monitoring and management systems, modules serve as the "industrial network interface core" responsible for collecting and transmitting equipment status data. It can interface with various sensors (such as temperature and pressure sensors) and equipment controllers in production lines, workshops, or factory areas, and collect real-time data on equipment operation status (such as motor current and equipment load rate)

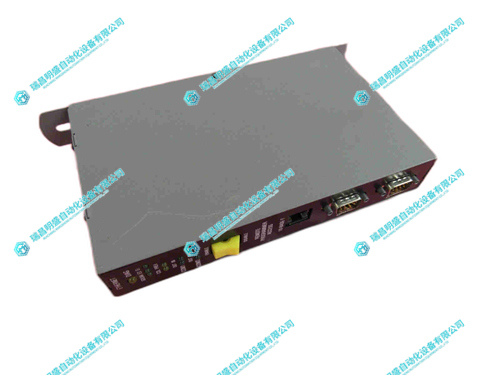

2.产 品 展 示

3.其他产品

4.其他英文产品

ASEA 2668 184-447 Communication Module

RadiSys 61-0475-12 Axis Control Module

RADISYS 97-9536-20 Ethernet Port Module

| 850-EP5NNG5HNNALAGASFCSENWBN2 | AMAT 0100-98072 | SN32HMYW-LNK-NS-00 |

| 850-EP5NNG5HNNALAGAPFBSENNBN | AMAT 0100-91087 | 48797303 |

| 850-EP5NNG5HNNAANMASFB1ECNAN | AMAT 0100-94078 | 135837-008 |

| 850-EP5NNG5HNNAANGMPHB3ACNBN | AMAT 0100-09110 | 48011401 |

| 850-EP5NNG5HNNAANGAPFCSENNBN | AMAT 0100-76029 | EPC-5-66 |

| 850-EP5NNG5HNNAANGAPFC2ASNBN | AMAT 0040-09098 | IC3600SVDA1A |

| 850-EP5NNG5HNNAANGAPFB2ESNBN | AMAT 0100-76258 | IC3600SVDA1 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218