GIDINGS&LEWIS DSA-007-230伺服处理器

1.产 品 资 料 介 绍:

GIDDINGS & LEWIS DSA-007-230 伺服处理器解析

一、产品概述

二、技术参数(典型特性)

英文资料:

GIDINGS&LEWIS DSA-007-230 servo processor analysis

1、 Product Overview

GIDINGS&LEWIS DSA-007-230 servo processor is a high-performance core control unit designed specifically for servo drive systems, responsible for the full chain function of "instruction reception feedback processing precision drive". It can accurately receive position, speed, and torque commands issued by the upper level motion control system (such as CNC controller, PLC), and analyze the commands in real time through the built-in high-speed processing unit; Simultaneously collect motor operation data (such as rotor position and actual speed) from feedback devices such as encoders, perform deviation calculation and control logic operations, and finally output precise control signals to servo motors to achieve closed-loop control of motion parameters. This processor is widely applicable to industrial equipment that requires precise motion control, such as CNC machine tools and automated production lines. With stable computing power and accurate control performance, it has become a key link in the servo system connecting the "control center" and the "execution motor", ensuring that industrial equipment achieves high-precision and high stability motion operations.

2、 Technical parameters (typical characteristics)

Product Model: DSA-007-230

Equipment type: Industrial grade servo processor, focusing on the core control and motion adjustment of servo drive system

Control mode: Supports triple closed-loop control mode, covering multi scenario motion requirements - closed-loop position control (positioning accuracy up to micrometer level, suitable for precision positioning scenarios such as machine tool feed axis positioning), closed-loop speed control (speed fluctuation ≤ 0.5%, strong resistance to load disturbance, suitable for stable spindle rotation), closed-loop torque control (torque output accuracy ≤ 1%, suitable for constant load scenarios such as material clamping and tension control). The three modes can be flexibly switched through software and can be adapted to different working conditions without hardware modification

Interface configuration: Equipped with rich interface resources, supporting digital/analog input/output (digital I/O is used for device start stop and fault alarm signal interaction, analog I/O is used for continuous speed/torque command input), and compatible with encoder feedback interface (adapted to incremental/absolute encoders, real-time collection of motor position and speed data, forming a closed-loop regulation loop). The interface specifications are standardized, and it can be connected to most industrial sensors and actuators without additional conversion modules

Dynamic performance: Equipped with high-speed signal processing chips and optimized control algorithms, the instruction response speed is fast (with a delay of ≤ 2ms from receiving instructions to outputting control signals), supporting high-frequency motion correction (hundreds of deviation calculations and instruction adjustments can be completed per second), and can achieve precise motion control (such as trajectory tracking error ≤ 0.01mm when multiple axes are linked), suitable for high-speed and high-precision motion scenes

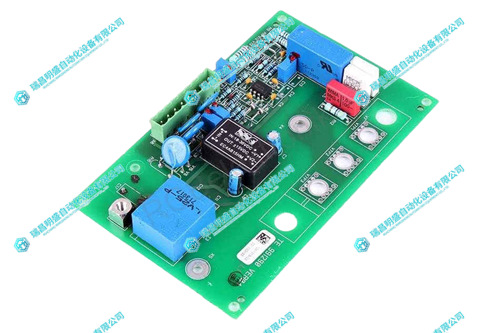

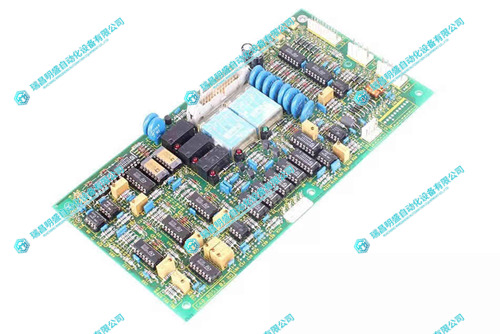

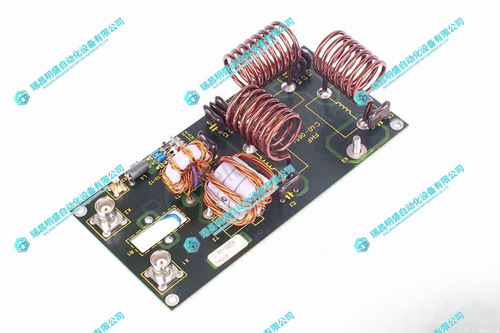

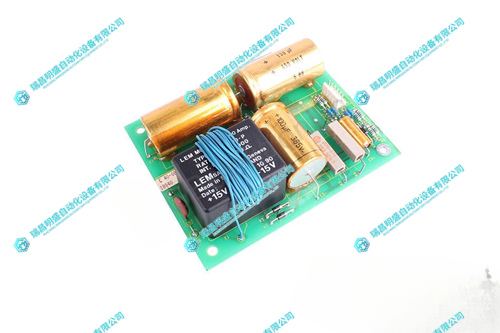

2.产 品 展 示

3.其他产品

INDRAMAT TDM1.3-050-300-W1-000 驱动模块

4.其他英文产品

IC3600EPSS1B power supply boar

| 8030-PS-10 | 6SC6500-0BC01 | X-DI 32 0 |

| 8030-LRK-100 | 531X301DCCAM1 | X-AI 32 01 |

| 8030-LOM112 | 531X301DCCALM1 | X-DO 12 5 |

| 8030-LOM-111 | 531X301DCCAKM1 | X-DO 12 01 |

| 8030-LIM-112 | 8030-CRM-211 | X-AO 16 5 |

| 8030-LIM-111 | 8030-CRM-210 | X-AI 16 51 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218