GIDINGS&LEWIS DSA030-230-S运动伺服控制器

1.产 品 资 料 介 绍:

GIDDINGS & LEWIS DSA030-230-S 运动伺服控制器解析

一、产品概述

二、技术参数(典型特性)

英文资料:

Analysis of GIDINGS&LEWIS DSA030-230-S Motion Servo Controller

1、 Product Overview

GIDINGS&LEWIS DSA030-230-S motion servo controller is a core equipment in the industrial field that focuses on precision motion control, undertaking the key functions of "instruction parsing motor drive accuracy guarantee". It can accurately control the three core parameters of servo motor speed, position, and torque, and ensure the accuracy and stability of motor motion through a built-in closed-loop feedback system (combined with encoder and other feedback devices to correct deviations in real time), avoiding control errors caused by load fluctuations and mechanical clearances. This controller is widely applicable to industrial equipment such as CNC machine tools and automated production lines that require high-precision and multi axis coordinated motion. With rich interface resources, it can easily integrate into existing control systems, becoming a key link between the "control center" and the "execution motor", providing reliable support for the precision motion needs of industrial scenes.

2、 Technical parameters (typical characteristics)

Product model: DSA030-230-S

Equipment type: Industrial grade motion servo controller, focusing on high-precision servo motor drive and motion control

Control mode: Supports triple closed-loop control - closed-loop position control (positioning accuracy up to micrometer level, suitable for precision positioning scenarios such as machine tool feed axis positioning), closed-loop speed control (speed fluctuation ≤ 0.5%, strong resistance to load disturbance, suitable for stable spindle rotation), closed-loop torque control (torque output accuracy ≤ 1%, suitable for constant load scenarios such as clamping devices and tension control). The three modes can be flexibly switched through software, covering multiple types of motion control needs

Interface type: Equipped with multi-channel digital/analog input/output interfaces (such as digital I/O for device start stop and fault alarm, analog I/O for speed/torque command input), while supporting encoder feedback interfaces (compatible with incremental/absolute encoders, real-time collection of motor position and speed data, forming closed-loop regulation), standardized interface specifications, and can be connected to most industrial equipment without additional conversion modules

Motor compatibility: It has a wide range of motor adaptation capabilities, compatible with various AC servo motors (such as permanent magnet synchronous AC servo motors) and DC servo motors, supporting motor models of different powers and rated voltages (such as AC 220V/380V, DC 24V/48V), and can adapt to the motor drive requirements of different devices without replacing the controller, reducing system integration complexity

Dynamic performance: Equipped with high-speed signal processing chips and optimized control algorithms, it has a fast response speed (instruction reception to motor action delay ≤ 2ms), supports high-frequency motion adjustment (such as hundreds of position corrections per second), and can achieve precise motion control (such as track tracking error ≤ 0.01mm when multiple axes are linked), suitable for high-speed and high-precision motion scenes

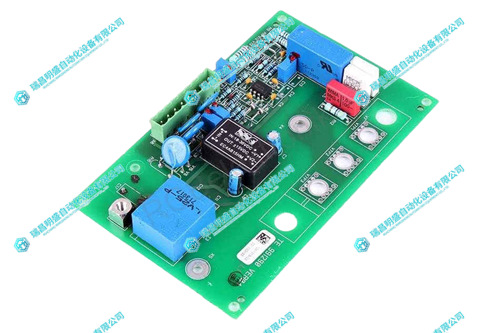

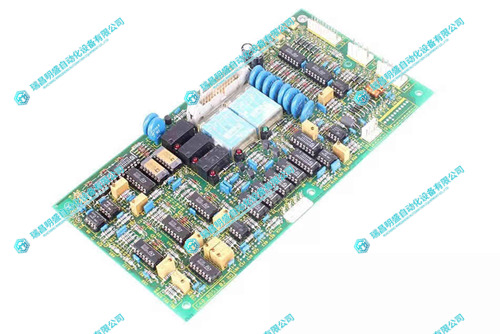

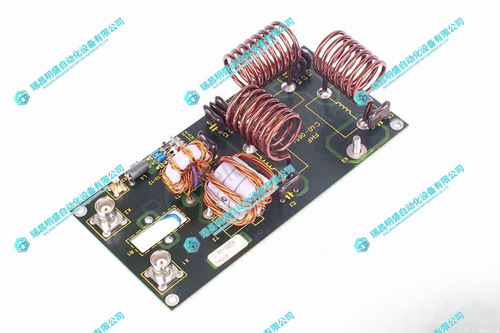

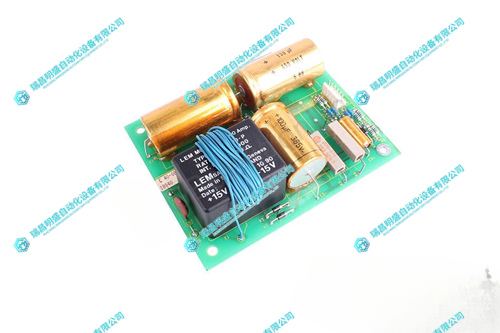

2.产 品 展 示

3.其他产品

INDRAMAT TDM1.3-050-300-W1-000 驱动模块

4.其他英文产品

Radisys ATCA-PP81 controller module

AMAT 0190-24282 encoder module

IC3600EPSS1B power supply boar

| 8030-RRK-100 | CACR-SR03BE13S | 8030-CRM-570 |

| 8030-ROM-871 | 531X301DCCAPM1 | 8030-CRM-565 |

| 8030-ROM-441 | 531X301DCCAPG1 | 8030-CRM-560 |

| 8030-ROM-271 | 531X301DCCAMM1 | 8030-CRM-540 |

| 8030-ROM-222 | 193X800DAG01 | 8030-CRM-512 |

| 8030-ROM-221 | 03-136531-00 | 8030-CRM-511 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218