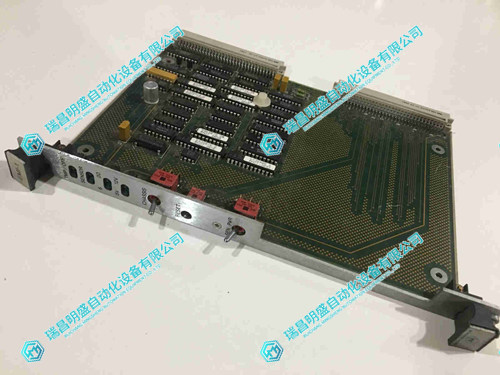

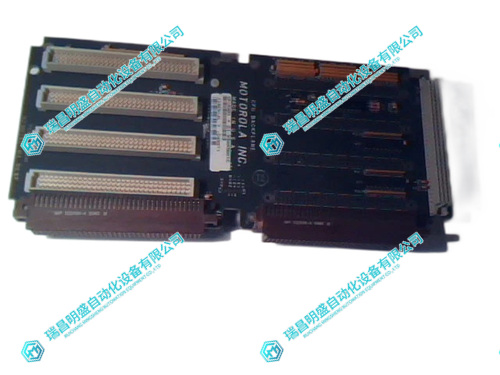

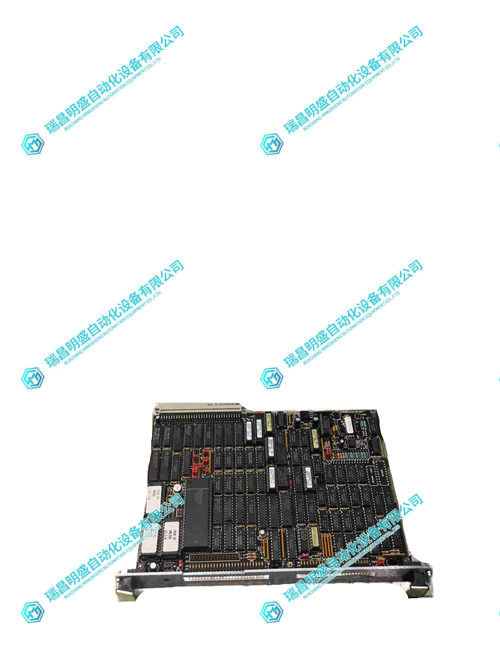

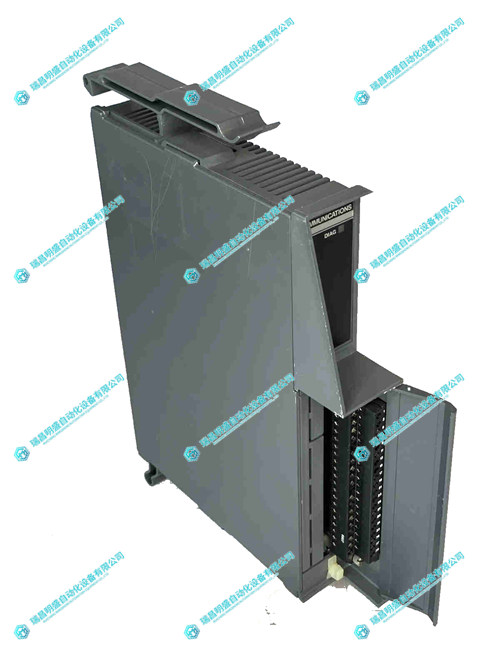

GIDINGS&LEWIS 502-03676-03可编程式逻辑控制器

1.产 品 资 料 介 绍:

一、产品概述

二、技术特性

英文资料:

1、 Product Overview

GIDINGS&LEWIS 502-03676-03, as the programmable logic controller (PLC) of the PiC900 series, plays a crucial role in central coordination in industrial automation systems. It is like the "smart brain" of industrial automation, mainly responsible for centralized management of logic control, sequence control, and collaborative operation between devices. In actual operation, the PLC can sensitively receive various signals from input modules, accurately control output modules according to pre-set programs, and drive various devices to complete automated operation processes in an orderly manner, laying a solid foundation for efficient and stable operation of industrial production.

2、 Technical characteristics

Programmable control, flexible customization of logic: 502-03676-03 supports users to write logic programs according to the needs of different industrial scenarios. Both complex sequential control processes and precise motion control tasks can be achieved through user-defined programs. For example, in the production line of automotive parts processing, specific programs can be written based on the processing technology of the parts to accurately control the sequence of each processing step, as well as parameters such as equipment start stop and operating speed, greatly improving the flexibility and pertinence of production.

Real time processing and efficient signal response: This PLC has excellent ability to quickly respond to input signals, and can react to changes in the status of on-site equipment in a very short time, achieving high-precision and high reliability control effects. In the automated warehousing system, when the cargo detection sensor detects that the cargo has arrived at the designated location, 502-03676-03 can quickly capture this signal and control the conveyor equipment to stop or start in a timely manner, ensuring accurate loading and unloading of the cargo and effectively improving the system's operational efficiency and stability.

Modular structure, convenient system construction: Adopting a modular design concept, it can be easily plugged into the PiC900 system rack. In the initial stage of system construction, engineers can flexibly select and combine modules such as CPU, I/O, servo drives, encoders, etc. according to actual production needs, to build a suitable industrial automation control system. During the operation of the system, if functions need to be expanded or modules need to be maintained, only the corresponding modules need to be plugged and unplugged, without the need for large-scale disassembly and re debugging of the system, which reduces maintenance costs and improves the scalability and maintainability of the system.

Interface compatibility and seamless system integration: 502-03676-03 has excellent compatibility with G&L series devices and can seamlessly connect with CPUs, I/O modules, servo drives, encoders, and other components within the series. In practical applications, compatibility between different devices is often a difficult problem in system integration. With good interface compatibility, this PLC enables close cooperation among devices, ensuring smooth signal transmission and accurate data exchange, providing convenience for system integration and optimization, and ensuring stable operation of industrial automation systems.

2.产 品 展 示

3.其他产品

4.其他英文产品

ABB UN0803B-P Printed Circuit Board

| 6ES5581-5LA11 | CACR-CSL15AAAY30 | Asyst 3200-1071-02 6018-1002-10B |

| 6ES5581-1EE15 | CACR-SR30SF1BSB-Y1 | ASYST 3000-1086-04A |

| 6ES5581-0RA12 | CACR-SR-30TZ9SMY01A | Asyst 3200-1044-02 |

| 6ES5581-0EE15 | CACR-HR-02BAB12Y5 | Asyst 3200-1223-02 |

| 6ES5581-0EB12 | CACR-CSL3600DAAB | Asyst 3200-4346-02 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218