GIDINGS&LEWIS 503-25209-01伺服控制板

1.产 品 资 料 介 绍:

闭环运动控制,精准把控运行轨迹

智能反馈处理,保障动作稳定流畅

多模式运行,灵活适配多样需求

可扩展性强,满足多元控制规模

工业级耐用性,从容应对恶劣工况

英文资料:

Closed loop motion control, precise control of operating trajectory

The 503-25209-01 servo control board uses advanced closed-loop control algorithms to accurately monitor and adjust the position, speed, and acceleration of the servo motor in all directions and in real time. In the field of precision machining, such as the grinding of high-end optical lenses, the surface accuracy of the lenses is required to reach the nanometer level. The control board continuously feeds back the actual operating data of the motor and fine tunes the motor output to ensure that the motion accuracy of the grinding equipment is maintained at a very high level, so that the processed lenses meet strict optical performance indicators, achieve high-precision motion control, and meet the ultimate pursuit of precision in industrial production.

Intelligent feedback processing ensures stable and smooth movements

Built in cutting-edge encoder signal processing function, capable of real-time and efficient collection of motor feedback signals. In the handling process of automated production lines, the robotic arm needs to be frequently started, stopped, and accurately positioned. The control board quickly analyzes the feedback data from the encoder, adjusts the motor operation status in a timely manner, and effectively avoids the shaking or positioning deviation of the robotic arm caused by inertia, load changes, and other factors, ensuring that each handling action is stable and smooth, greatly improving the stability and reliability of the production line operation.

Multi mode operation, flexible adaptation to diverse needs

Supports multiple operating modes such as position control, speed control, and torque control. In CNC machine tools, when processing parts of different materials and shapes, the mode can be flexibly switched according to process requirements: in the rough machining stage, switch to torque control mode, the motor outputs a large torque, and excess materials are quickly removed; During precision machining, switch to position control mode to precisely control the tool movement and ensure the dimensional accuracy of the parts; During the rapid movement and positioning of the tool, the speed control mode allows the motor to respond quickly and improve machining efficiency. This multi-mode operation feature enables the device to easily cope with various complex industrial scenarios.

Strong scalability to meet diverse control scales

It has excellent scalability and can work in parallel with multiple servo drives and control modules. In large-scale automated logistics and warehousing systems, it is necessary to simultaneously control multiple stacker cranes, shuttle cars, and other equipment. The 503-25209-01 servo control board can be connected to multiple drives to control the motors of different devices, achieving large-scale precision control of multiple axes and channels. It is easy to build complex automation control systems to adapt to the constantly expanding production scale and diversified control needs.

Industrial grade durability, capable of handling harsh working conditions with ease

Specially designed for industrial environments, capable of withstanding strong vibrations (such as high-frequency vibrations generated during machine tool processing), significant temperature fluctuations (such as high-temperature environments in metallurgical workshops), and complex electromagnetic interference (such as strong electromagnetic areas near power equipment). In mining equipment, the equipment is exposed to harsh working environments for a long time. With its sturdy hardware design and good electromagnetic shielding performance, the control board always maintains stable operation, ensuring precise control of the equipment motor, guaranteeing the continuity of mining operations, ensuring long-term reliable operation, and reducing equipment downtime due to malfunctions.

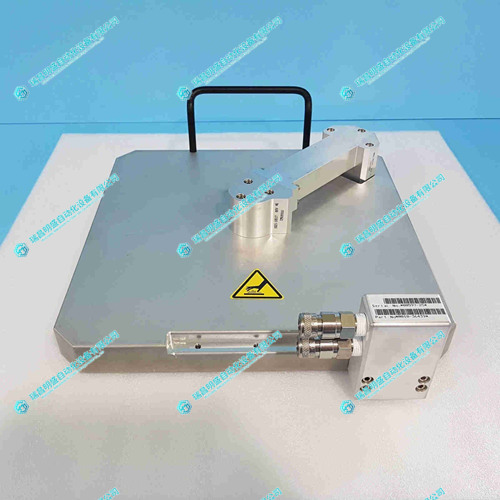

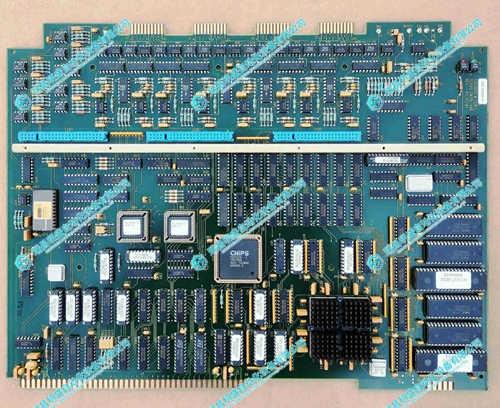

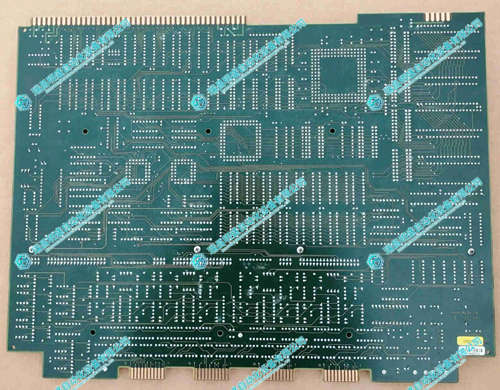

2.产 品 展 示

3.其他产品

4.其他英文产品

Asea EB0524B01 driver input power board

ABB UN1024c-P Remote Terminal Module

ABB 70BK03c-E Control I/O Module

| 6DD2920-0AS0 | CACR-A5-SU23GC | PPC902CE101 |

| 6DD1660-0AE0 | CACR-SR10BB1AF | 6ES5497-8MA11 |

| 6DD1660-0AD0 | 6SC9311-3FK15 | PFTL101B 2.0KN |

| 6DD1645-0AF2 | CACR-IR050505FD | 6ES5497-4UD11 |

| 6DD1645-0AE1 | CACR-HR01BAB11Y11 | UFC718AE101 |

| 6DD1645-0AE0 | CACR-SR20BE13FY8 | 6ES5135-3KA13 |

| 6DD1642-0BC0 | CACR-IR44SC1 | 6ES5431-8MD11 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218