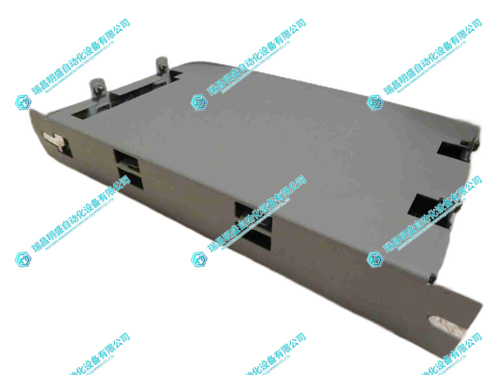

GIDINGS&LEWIS M10173888R4以太网模块

1.产 品 资 料 介 绍:

一、产品概述

二、产品特点

英文资料:

1、 Product Overview

In the PiC900 series control system ecosystem built by Giddings&Lewis, the M.1017.388R4 Ethernet module occupies a key hub position for data transmission and network interconnection. It is designed specifically for industrial automation systems, aiming to break down data barriers between devices and achieve high-speed and stable data flow. With the help of standard Ethernet interfaces, M.1017.388R4 can build a real-time communication bridge between controllers, I/O modules, servo drives, and other intelligent devices, allowing different devices to "talk" and support distributed control modes, enabling remote monitoring and breaking through geographical limitations in industrial production management and control, moving towards intelligence and efficiency.

2、 Product Features

High speed network communication, enjoy low latency data flow: Deeply supports industrial Ethernet standards, which means it can transmit data at extraordinary speeds and control latency at extremely low levels. On automated production lines, a large amount of equipment operation data needs to be uploaded in real-time to the central control system for analysis and decision-making. M.1017.388R4 can easily handle this, quickly transmitting equipment operation status and product quality inspection data collected by sensors, ensuring timely issuance of control instructions and reception of equipment feedback data, ensuring smooth operation of the production line, and greatly improving production efficiency.

Multi device interconnection to build a distributed control network: With powerful multi device connectivity, it can work together with multiple controllers and modules simultaneously. In large industrial parks, production equipment in different areas is managed by their own controllers. M.1017.388R4 can connect these dispersed controllers and related modules to achieve data sharing. Equipment in various regions can collaborate based on shared data, for example, in automotive manufacturing factories, stamping workshops, welding workshops, and painting workshops, equipment can be interconnected through this module to jointly complete the production and assembly of automotive parts, achieving efficient and coordinated operation of distributed control systems.

Real time data processing to ensure synchronized and stable actions: proficient in real-time collection and transmission of industrial control data. In the scenario of robot collaboration, multiple robots need to work closely together to complete complex tasks. M.1017.388R4 collects real-time data on the position, posture, and other aspects of each robot, and quickly sends this data to other related robots and control systems to ensure precise synchronization of robot actions, avoid collisions, maintain stable system operation, and provide solid support for high-precision and highly collaborative industrial operations.

Industrial grade reliability, capable of handling harsh working conditions with ease: carefully designed for the complexity of industrial environments, it has excellent anti electromagnetic interference performance and can effectively shield strong electromagnetic interference generated by frequency converters, large motors, etc. in the workshop, ensuring the accuracy and stability of data transmission; Excellent anti vibration ability enables it to work stably in continuous vibration environments such as machine tool processing and production line operation, without fear of the impact of vibration on internal circuits and data transmission. It is suitable for long-term uninterrupted operation and ensures the reliable operation of industrial automation systems.

2.产 品 展 示

3.其他产品

4.其他英文产品

UFC760BE143 inverter high-voltage board

ABB 70EB01b-E digital input module

| 6DD1607-0EA2 | 6SC9811-2BE50 | 6DD1681-0CB2 |

| 6DD1607-0EA1 | CACR-05-TF2ES-AF | 6DD1681-0CA8 |

| 6DD1607-0EA0 | CACR-HR10AABY8 | 6DD1681-0CA2 |

| 6DD1607-0CA1 | 6SC6113-0HA00 | ICS TRIPLEX TC -505-02-4M5 |

| 6DD1607-0CA0 | CACR-SR03SZ1SSY226 | ICS TRIPLEX TC 501-02 _4M5 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218