GIDINGS&LEWIS 502-03642-00 伺服控制器

1.产 品 资 料 介 绍:

一、产品概述

二、产品特点

英文资料:

1、 Product Overview

In the PiC900 series control system layout constructed by Giddings&Lewis, the 502-03642-00 servo controller can be regarded as the core hub of precision motion control. It focuses on precisely controlling the operation of servo motors with excellent performance, and through closed-loop control technology, it provides comprehensive and real-time fine control of the motor's position, speed, and acceleration. Whether it is the multi axis collaborative operation of complex industrial machinery or the micro nano level positioning of high-precision machining equipment, this controller can handle it with ease and accurately achieve coordinated control of complex movements. Its compact and exquisite design enables seamless integration into various industrial control systems, helping to create micrometer level precision components in the field of high-precision machining; Ensure efficient and stable operation of production lines in the field of automation equipment; In robot systems, endowing the robotic arm with flexible and precise motion capabilities injects strong power into industrial automation processes.

2、 Product Features

Precise motion control creates excellent precision: a closed-loop control mode that deeply supports position, velocity, and acceleration. In high-end optical lens grinding equipment, the surface accuracy of the lens is extremely high. The 502-03642-00 servo controller continuously collects the actual operating data of the motor, compares it with the preset parameters, and continuously adjusts the motor output to maintain the motion accuracy of the grinding equipment at the nanometer level, ensuring that each grinding action is smooth and accurate, meeting the strict requirements of optical lenses for surface roughness and curvature accuracy, and providing a solid precision guarantee for the precision manufacturing industry.

Dynamic optimization function, extending device lifespan: Equipped with advanced motion curve optimization algorithms, it can intelligently plan the running trajectory of the motor. In the handling process of automated production lines, the mechanical arm frequently starts and stops, and traditional operation methods are prone to vibration and mechanical impact, accelerating equipment wear. And this controller can optimize the motion curves during the start-up, acceleration, uniform speed, and deceleration stages, making the robotic arm move more smoothly, effectively reducing vibration, reducing the impact between mechanical components, significantly extending the overall service life of the equipment, and reducing the maintenance cost of enterprise equipment.

Multi axis support for efficient collaborative operation: With strong multi axis collaboration capabilities, it can work seamlessly with multiple servo drives. In large gantry machining centers, complex parts require multi axis linkage such as X, Y, and Z. The 502-03642-00 servo controller can accurately coordinate the operation of each axis motor, ensuring precise cutting of the tool along complex spatial curve trajectories. The synchronization of each axis motion is extremely high, greatly improving machining efficiency and part accuracy, and easily coping with complex industrial control scenarios with multiple axes and tasks.

Real time instruction response enhances system agility: With high-speed processing capability, it can quickly respond to control signals from the CPU or control system. In the high-speed sorting system, when the sensor detects product information, the CPU immediately issues sorting instructions, and the 502-03642-00 servo controller responds quickly, instantly driving the motor action,

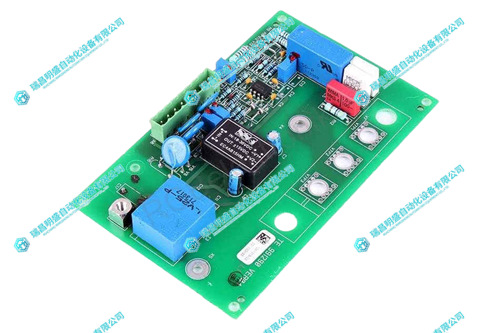

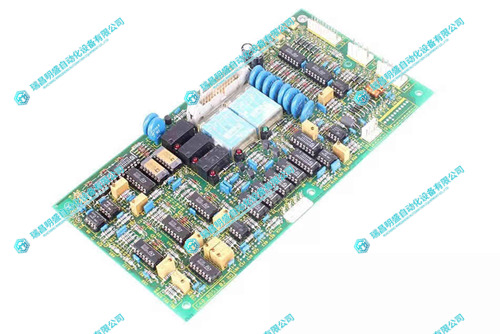

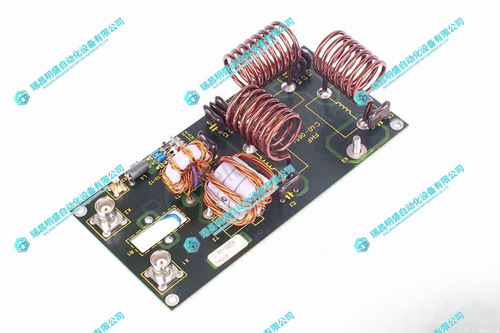

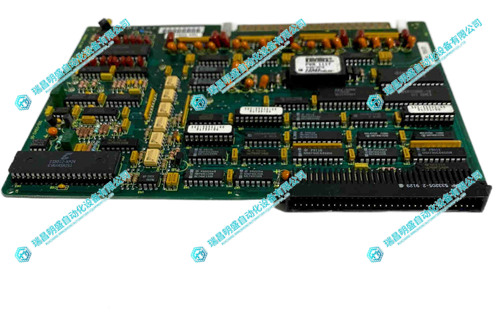

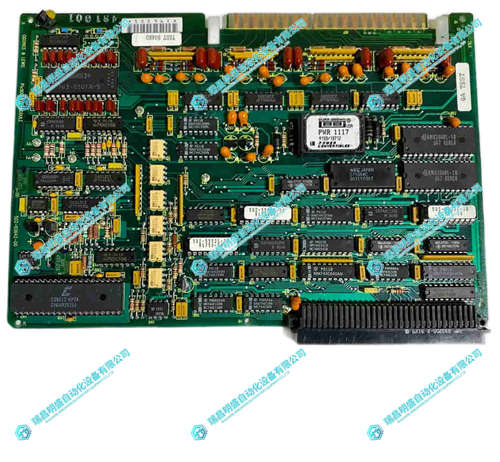

2.产 品 展 示

3.其他产品

4.其他英文产品

ABB 70EB01b-E digital input module

ABB 70BV05a-ES bus controller module

| 6DD1606-1AC0 | TRICONEX NCM4329G | ICS TRIPLEX T9802 |

| 6DD1606-0AD1 | DECS-100 | TRICONEX 7400206-100 |

| 6DD1606-0AD0 | SDCS-CON2B-2A | TRICONEX 9561-810 |

| 6DD1602-0AE0 | IS210MACCH1AFG | TRICONEX 9563-810 |

| 6DD1601-0AH0 | CACR-SR03BY1SG-E | TRICONEX 3481 |

| 6DD1601-0AE0 | CACR-SR10BC1KSY262 | TRICONEX 9662-610 |

| 6DD1600-0BA2 | CACRSR20TB5BM | TRICONEX D02401 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218