GIDINGS&LEWIS 503-26683-01 以太网模块

1.产 品 资 料 介 绍:

产品概述

产品应用领域

英文资料:

Product Overview

GIDINGS&LEWIS 503-26683-01 Industrial Ethernet module is the "high-speed data hub" for industrial systems. Through a standard Ethernet interface, it can achieve real-time data exchange between CNC machine tools, automation equipment, and upper control systems, efficiently transmitting key data of controllers, I/O modules, and servo systems. It not only supports remote monitoring (without on-site duty), data acquisition (providing basis for analysis), but also assists in industrial network integration (breaking down equipment information barriers), providing core communication support for industrial intelligent operation.

Product application areas

Numerical Control Machine Tool (CNC)

Connect the machine tool with the MES/ERP management system of the factory, and on the one hand, upload real-time data such as machining progress, tool wear, and product accuracy, making it convenient for management personnel to grasp production dynamics; On the other hand, it can remotely transmit machining programs, adjust process parameters, avoid delays in manual on-site operations, and provide feedback on abnormal machine operation (such as overload and faults), timely warning and maintenance, and improve machining efficiency and management convenience.

Industrial automation production line

Connect the controllers, sensors (such as material position sensors), and actuators (such as conveyor belt motors) of the production line in series to collect data from various links (such as material conveying speed and equipment temperature). Management personnel optimize production scheduling based on data (such as adjusting production pace according to material inventory), reduce downtime caused by information gaps, and improve the automation management level and overall operational stability of the production line.

robot system

Realize network communication between the robot controller and the upper system. The upper system can remotely issue task instructions (such as assembly steps and handling paths), while the robot provides real-time feedback on its operating status (such as joint load and grasping accuracy). When encountering task adjustments, remote scheduling can be achieved without on-site programming, and it can also support multi robot collaborative work (such as division of labor to assemble the same workpiece), enhancing the flexibility of robot applications.

Packaging and Printing Machinery

Real time uploading of equipment operating status (such as packaging speed, printing drum speed), production data (such as daily output, material loss), and fault information (such as paper jam, insufficient ink) to the monitoring system. Management personnel can remotely troubleshoot problems (such as determining the cause of faults through data), arrange maintenance in a timely manner, avoid batch production delays caused by equipment downtime, and ensure stable packaging and printing quality.

Experimental and testing platform

Provide real-time data transmission interfaces for experimental equipment (such as motor test benches) and testing systems, quickly transmitting key parameters (such as speed, torque, pressure) during the experimental process to the analysis terminal. Researchers can monitor data changes in real time (such as observing whether parameters meet expectations), adjust experimental conditions in a timely manner, and store data for subsequent review and analysis, ensuring the accuracy and traceability of experiments and tests.

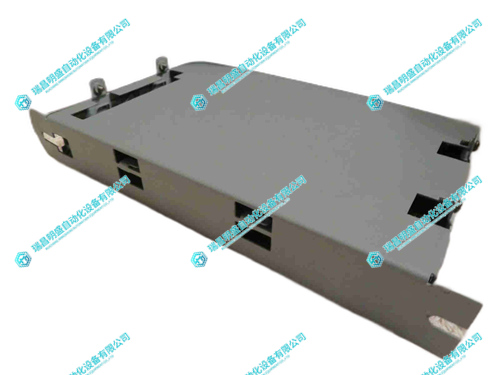

2.产 品 展 示

3.其他产品

4.其他英文产品

GE DS3800HMPK1K1K Controller Module

PXAA401 3BSE017233R1 Controller

Gasonics L-3510 486 Control Motherboard

| 6ES5095-8ME01 | 6SC9830-0HG20 | PCD244A101 |

| 6ES5095-8MC03 | CACR-IR20SB | PDD500A101 |

| 6ES5095-8MC02 | CACR-CSL2200DAAA, | TRICONEX Al2351 |

| 6ES5095-8MB01 | 6SC9111-2AE35 | PDD200A101 |

| 6ES5095-8MA05 | CACR-SR15SZ1SD-Y77 | 8101-HI-TX-02 |

| 6ES5095-8MA01 | 6SC9311-2GF25 | LDSYN-101 |

| 6ES5090-8MA01 | CACR-SR10SB1AF | 6ES5521-8MA22 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218