GIDINGS&LEWIS 502-02748-05阀门驱动器

1.产 品 资 料 介 绍:

产品概述

产品应用领域

英文资料:

Product Overview

GIDINGS&LEWIS 502-02748-05 valve actuator is the "precision control core" of industrial fluid control. It receives instructions from the central control board, performs high-precision control of the opening and closing of electric/pneumatic valves, and has fast response characteristics. It can ensure stable operation of hydraulic, pneumatic, and fluid systems, avoid medium conveying deviations, and provide support for precise control in various industrial scenarios.

Product application areas

Numerical Control Machine Tool (CNC)

Control the hydraulic fixture valve to ensure that the workpiece is firmly clamped without displacement; Adjust the flow rate of the coolant valve to meet the requirements of high-speed cutting and precision machining (preventing tool overheating and ensuring machining accuracy); Control the lubrication system valves to provide timely lubrication for moving parts, reduce wear, and assist in automated hydraulic control of the machining process.

Industrial automation production line

Through pneumatic/hydraulic valve control, the material flow at the conveying station is uniformly controlled (to prevent accumulation), the sorting station is accurately classified (to prevent misclassification), and the assembly station is stably operated (to prevent assembly deviation), thereby improving the overall operational accuracy and stability of the production line and reducing downtime adjustment time.

robot system

Drive the pneumatic/hydraulic valves of the end effector/gripper, accurately adjust the clamping force (to prevent damage or detachment of the workpiece), control the speed and position of the handling action, ensure that the robot moves accurately when grabbing and transferring workpieces, and adapt to the requirements of assembly, handling and other scenarios.

Packaging and Printing Machinery

Control the feeding valve to ensure uniform conveying of packaging materials/printing paper (preventing deviation and waste); Adjust process valves (such as ink and glue valves) to ensure firm packaging sealing and uniform printing color, achieve synchronous and stable packaging/printing, and improve product consistency in mass production.

Fluid control and experimental platform

In scientific research experiments, precise adjustment of gas/liquid flow rate and pressure is used to simulate specific operating conditions; In the testing bench or production process, stable control of medium parameters ensures accurate experimental data and compliance with production processes, meeting the needs of scientific research and industrial fluid control.

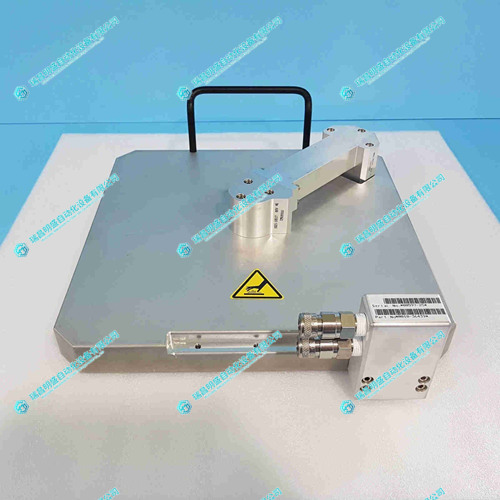

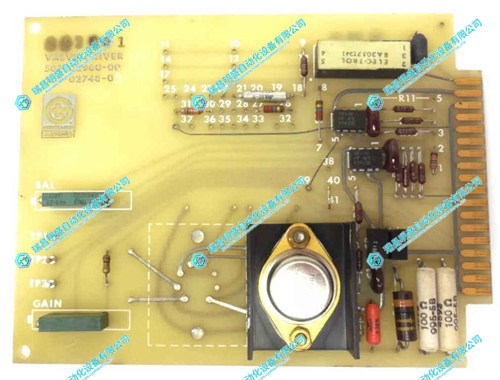

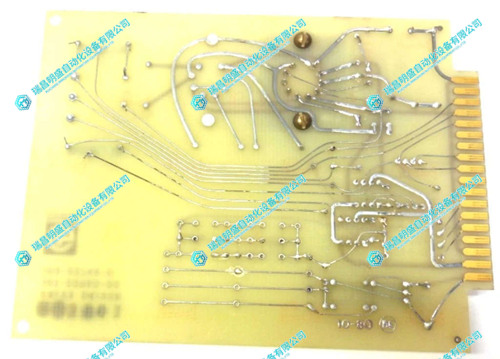

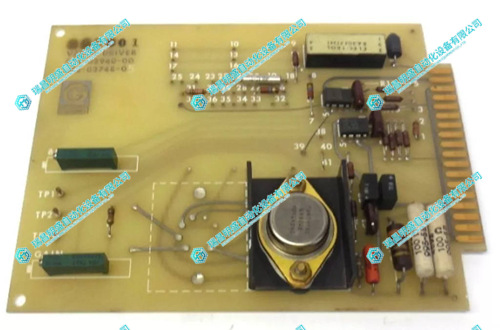

2.产 品 展 示

3.其他产品

4.其他英文产品

BERGER LAHR TLC411F Stepper Motor Contro

Gasonics 90-1079 Fault Detection Module

GE DS3800HMPK1K1K Controller Module

| 6ES5240-1AA21 | CACR-UP6AAA | TRICONEX 3721 |

| 6ES5188-3UH41 | CACR-TM333Z1SPY8 | PPE091A101 |

| 6ES5188-3UA12 | CACR-SR02BE12G-E | UAD206A101 |

| 6ES5187-5UA11 | 6SC6101-4B-Z | 6ES5375-0LB11 |

| 6ES5185-3UA33 | CACR-SR10SZ1SS | XDD501A101 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218