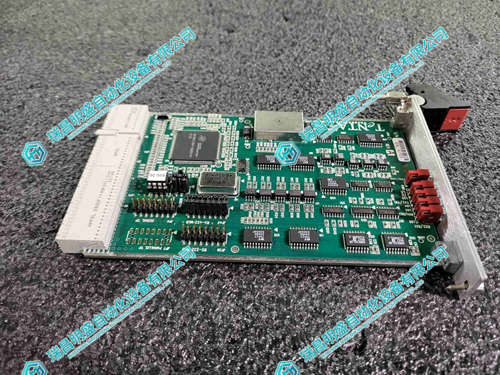

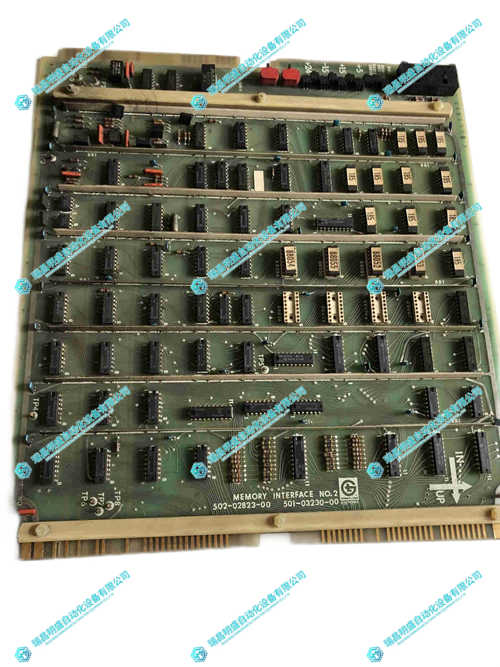

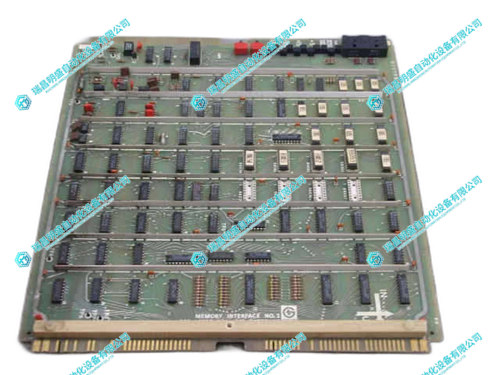

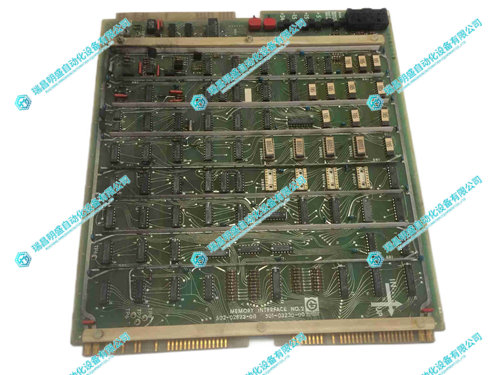

GIDINGS&LEWIS 502-02823-00存储板

1.产 品 资 料 介 绍:

产品概述

产品应用领域

英文资料:

Product Overview

The GIDINGS&LEWIS 502-02823-00 storage board is the "data safe" for industrial control systems, designed specifically for storing critical programs, parameters, and system data. It can work in conjunction with the central control board and I/O modules, ensuring reliable storage and high-speed read-write capabilities to prevent data loss and call delays, providing core data support for the stable operation and repetitive operation of CNC machine tools and automation systems.

Product application areas

Numerical Control Machine Tool (CNC)

Store machining programs (such as cutting path programs for complex parts), tool parameters (such as tool compensation values), and system configuration data, supporting unified management of programs for multiple machine tools. Even if the machine tool is powered off or restarted, the data can be fully preserved, avoiding reprogramming, ensuring machining continuity, and reducing downtime.

Industrial automation system

Save control parameters of the production line (such as conveyor belt speed, assembly accuracy threshold), process flow (such as process sequence, inspection standards), and equipment status information. When the system fails or upgrades, data can be quickly read to restore production without the need for re debugging, improving automation management efficiency.

Robot control system

Store the action program of the robot (such as assembly steps), motion path (such as welding trajectory), and process parameters (such as grasping force). With stable storage capacity, it ensures that the robot can accurately reproduce the preset actions every time it performs a task, avoiding job errors caused by data deviations.

Packaging and Printing Machinery

Save packaging programs (such as sealing temperature, packaging size parameters), printing parameters (such as ink concentration, overlay accuracy data), and process settings. During mass production, there is no need to repeatedly adjust parameters, and stored data can be directly called to achieve efficient and unified production standards, thereby improving batch production efficiency.

Experimental and testing platform

Store test programs (such as motor performance testing procedures) and experimental data (such as speed and torque records). Researchers can access historical data for comparative analysis at any time, or repeatedly call testing programs to conduct the same experiment, ensuring the repeatability of the experiment and the accuracy of data analysis.

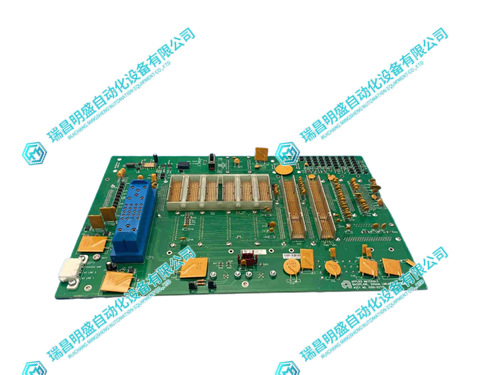

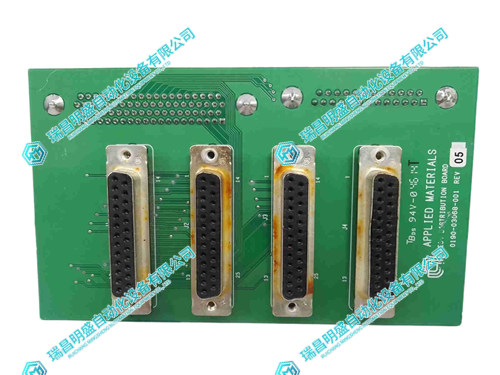

2.产 品 展 示

3.其他产品

4.其他英文产品

Magnetek 46S03345-0400 Control Armature

Gasonics 90-1061 Printed Circuit Board

BERGER LAHR TLC411F Stepper Motor Contro

| 6ES5252-4BA11-2EA1 | 6SC9811-4BC10 | TOSHIBA UTLH21 |

| 6ES5247-5AA31 | CACR-SR44BB1AMY114 | TRICONEX 3806E |

| 6ES5247-4UA31 | 6SC6140-0FE01 | 10106/2/1 |

| 6ES5246-5AA31 | CACR-IR-020202F | TRICONEX 3603B |

| 6ES5246-4UA41 | 6SC6110-6AA00 | TRICONEX 3623T |

| 6ES5244-5AA31 | CACR-HR02BAB12 | IC660BBD101 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218