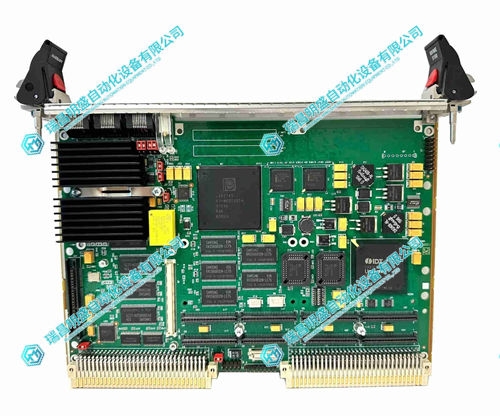

GIDINGS&LEWIS 502-03638-11 CPU处理器模块

1.产 品 资 料 介 绍:

Giddings & Lewis 502-03638-11 CPU 处理器模块介绍

一、产品概述

二、产品特点

(一)高性能处理能力

(二)模块化设计

英文资料:

Introduction to Giddings&Lewis 502-03638-11 CPU Processor Module

1、 Product Overview

The Giddings&Lewis 502-03638-11 CPU processor module is the core processing unit of the PiC900 control system and can be called the "brain" of the entire control system. It shoulders three core missions: firstly, to run user written control programs and convert preset control logic into actual device action instructions; The second is to process various logical instructions and motion control instructions, accurately coordinate the movement rhythm and sequence of each component of the equipment; The third is to comprehensively manage the input/output (I/O) modules and communication functions of the system, ensuring efficient flow of data within the system and between external devices. Its performance directly determines the processing capability, response speed, and operational efficiency of the PiC900 control system, and is a key core component for ensuring the stable and efficient operation of industrial automation equipment.

2、 Product Features

(1) High performance processing capability

Powerful hardware support: The module integrates an industrial grade CPU, which has been specially optimized and has excellent computing performance. It can perform logic control tasks at high speed (such as device start stop logic judgment, fault interlock protection), complex arithmetic operations (such as motion trajectory coordinate calculation, process variable data processing), and high-precision motion control tasks (such as multi axis synchronous motion instruction generation). Even in the face of dense instruction streams, it can respond quickly and process efficiently, avoiding device control errors caused by computational delays.

Multi task parallel processing: Supports multi task parallel processing technology, which can schedule multiple independent control tasks simultaneously. For example, in an automated production line, it can not only process the speed control task of the conveyor belt in real time, but also synchronously execute the position positioning task of the sorting machinery, and balance equipment status monitoring and data acquisition tasks. This multitasking parallel capability greatly improves the overall response speed of the system, ensuring smooth connection of device actions and avoiding the decrease in production efficiency caused by task queuing and waiting.

(2) Modular design

Convenient installation and adaptation: Adopting a plug-in structure design, staff do not need complex wiring operations. They only need to align the module with the corresponding slot of the PiC900 series rack and gently insert it to complete the installation. This design not only simplifies the installation process and reduces installation difficulty, but also ensures stable and reliable electrical connections between modules and racks, reducing contact failures caused by improper installation.

Flexible combination expansion: With excellent compatibility, it can be flexibly combined with PiC900 series input modules (such as digital input modules, analog input modules), output modules (such as DC output boards, AC output boards), encoder modules (such as incremental encoder input modules), and communication modules (such as fieldbus communication modules). Users can freely match modules according to their actual control scale (such as small single machine control, medium-sized production line control, large complex system control) and functional requirements, avoiding functional redundancy or insufficiency, and achieving personalized customization of the control system.

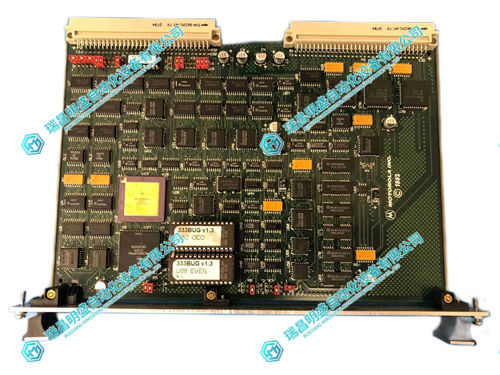

2.产 品 展 示

3.其他产品

4.其他英文产品

ADLINK CPS-H325/24 power module

ASEA YM316001-NL Double Plate Component

Foxboro FBM230 Communication Module

| UR8NH | CACR-03-DS3BUHY5/DAI | RB945G |

| UR8LH | CACR-IR20SEB | ATCA-FM40 |

| UR8HH | CACR-SR05SZ1SSY85 | 115970-010 |

| UR8GH | CACR-SR20BE12G-E, | 44063909 |

| UR8FV | CACR-CSL20DL16AAA, | EPC-8A |

| UR8FH | CACR-SR10BZ1SF | 60-0504-03 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218