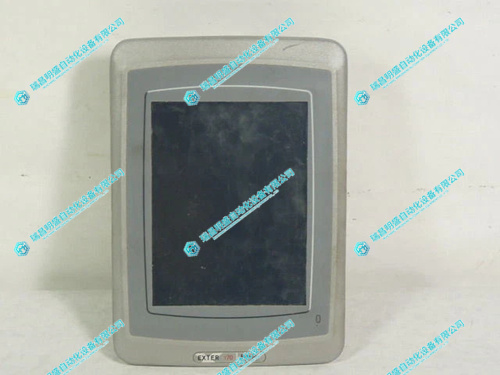

GIDINGS&LEWIS M.1302.8206 触摸屏

1.产 品 资 料 介 绍:

Giddings & Lewis M.1302.8206 工业触摸屏介绍

一、产品概述

二、产品应用领域

(一)数控机床操作

(二)自动化生产线监控

(三)过程控制与工业设备管理

英文资料:

Introduction to Giddings&Lewis M.1302.8206 Industrial Touchscreen

1、 Product Overview

Giddings&Lewis M.1302.8206 Industrial Touch Screen is an interactive device designed specifically for PiC series control systems. It plays a key role as a "human-machine dialogue bridge" in industrial automation control processes. It has an intuitive human-machine interface (HMI) as its core, providing operators with a comprehensive platform that integrates operation, monitoring, and parameter settings. Through this touch screen, operators can obtain real-time device operating status, accurately adjust control parameters, clearly monitor machine action details, and timely grasp alarm information, effectively reducing the complexity of industrial equipment operation and improving control efficiency and accuracy. It is an important component of PiC series control systems to achieve efficient human-machine interaction.

2、 Product application areas

(1) CNC machine tool operation

In the field of CNC machine tools, this industrial touch screen is widely compatible with various equipment such as lathes, milling machines, grinders, and machining centers, providing strong support for the precise operation of CNC machine tools. In terms of interface display, it visually presents the real-time position of the machine tool (such as tool coordinates, workpiece coordinates), motion status (such as spindle speed, feed rate), and machining progress (such as machining time and remaining machining amount) in a graphical manner, allowing operators to have a clear understanding of the machine tool operation. In terms of operational functions, operators can directly adjust parameters (such as cutting parameters and compensation parameters), select programs (choose corresponding solutions from stored machining programs), and execute control instructions such as start and stop through the touch screen, without the need for complex physical buttons, simplifying the operation process of CNC machine tools and improving machining efficiency.

(2) Automated production line monitoring

The efficient operation of automated production lines relies on real-time monitoring and flexible intervention, and this touch screen plays an important role in this scenario. It can centrally display the operating status of each workstation on the production line (such as normal operation, standby, faults), fault alarm information (such as equipment abnormal parts, fault types), and production data (such as output, pass rate, production pace). When there are abnormalities in the production line or when it is necessary to adjust the production pace, operators can intervene in real time through the touch screen, such as adjusting the sequence of equipment actions (such as optimizing the action process of sorting machinery), modifying the operating speed (such as adjusting the transmission speed of conveyor belts), to ensure that the production line always maintains an efficient and stable operating state, reducing production delays caused by faults or improper parameters.

(3) Process Control and Industrial Equipment Management

In industries such as metallurgy, chemical engineering, and energy that require extremely high production process parameters, this industrial touch screen has become a core tool for process control and equipment management. It can real-time collect and display key parameters in the production process, such as furnace temperature in the metallurgical industry, reactor pressure in the chemical industry, pipeline flow in the energy industry, etc. At the same time, when the parameters exceed the preset safety range, the touch screen will immediately pop up an alarm message to remind the operator to handle it in a timely manner, avoiding safety accidents or product quality issues.

2.产 品 展 示

3.其他产品

4.其他英文产品

Foxboro FBM230 Communication Module

Fanuc A06B-6114-H205 servo amplifier

GE 151X1235DB15SA01 power converter

| UR6CH | CACR-SRA5AB | 859-8379-001B |

| UR6AV | CACR-UP60AAB | PRE-913425 |

| UR1800 | CACR-SR10B21SSY367 | EXP-MX |

| UNS0881a-P,V1 3BHB006338R0001 | CACR-SR05BC1ES-Y278 | 97-9525-20 |

| TRICONEX 3805H | CACR-02-SU3CY1 | EPC5A-CFB001 |

| TRICONEX 3625A | CACR-SR07BE12M | 851-8554-003E |

| TRICONEX 4351B | CACR-IR10SFB | EPC-9 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218