GIDINGS&LEWIS 502-03673-00逻辑控制器

1.产 品 资 料 介 绍:

Giddings & Lewis 502-03673-00 逻辑控制器介绍

一、产品概述

二、产品应用领域

(一)数控机床

英文资料:

Introduction to Giddings&Lewis 502-03673-00 Logic Controller

1、 Product Overview

The Giddings&Lewis 502-03673-00 logic controller is a key module in the PiC series control system that undertakes the core tasks of "logical operations" and "sequential control", and can be regarded as the "intelligent decision-making center" of industrial automation systems. Its core functions revolve around digital logic processing and signal management: on the one hand, it can receive digital signals from sensors and input modules, execute complex digital logic operations such as AND, OR, NOT, XOR through built-in logic operation units, and generate accurate control decisions; On the other hand, according to the preset control program, manage the flow of input and output signals, control the sequential actions of equipment (such as process start and stop, action switching), and monitor the equipment status in real time to ensure the orderly and stable operation of the entire control system.

In the context of industrial automation, whether it is the coordination of machining actions of CNC machine tools, the collaboration of multiple devices in automated production lines, or the safety logic judgment of process control systems, this logic controller can provide reliable control support and is the core control unit to ensure the efficient and safe operation of industrial equipment.

2、 Product application areas

(1) CNC machine tool

In the field of CNC machine tools, this logic controller is the core for achieving precise coordination of machining actions and equipment safety control, directly determining the machining accuracy and operational stability of the machine tool.

Core Motion Logic Control: Focusing on the key moving components of CNC machine tools, executing logical operations for feed axis, spindle, and tool control. For example, in milling, according to the machining program instructions, the motion trajectory logic of the feed axis is calculated (such as path judgment for linear interpolation and arc interpolation) to ensure that the tool moves accurately according to the preset trajectory; Control the start stop and speed switching logic of the spindle, dynamically adjust the spindle speed according to the workpiece material and cutting process, and avoid machining errors or tool damage caused by mismatched speeds; At the same time, manage the logic of tool replacement, determine the location of the tool library and the matching degree of tool models, ensure the safety and efficiency of tool replacement actions, and avoid tool collision accidents.

Sequential management of auxiliary devices: responsible for controlling the sequential actions of machine tool fixtures, hydraulic or pneumatic devices, and building a complete closed-loop machining process. For example, before processing, according to the logical sequence of "fixture detection → workpiece clamping → pressure confirmation", control the action of the fixture solenoid valve to ensure that the workpiece is firmly clamped; During the machining process, according to the cutting progress, the hydraulic device is triggered to achieve the lifting and rotation of the worktable, and the feed axis is used to complete multi-faceted machining; After the processing is completed, control the reset of each auxiliary device in the order of "coolant off → spindle stop → fixture release" to ensure the safety of machine operation and the standardization of the process.

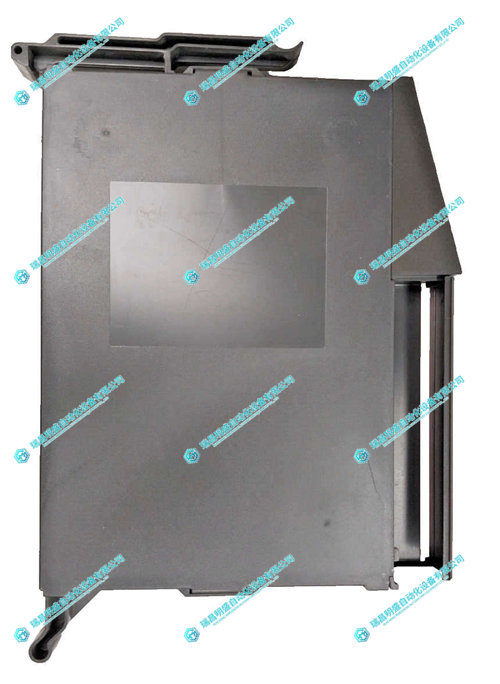

2.产 品 展 示

3.其他产品

4.其他英文产品

ASEA DSPC150 Robot Control Board

| SC722B-001 | SC723B00101 | SCE904AN-001-01 |

| SC722A-001-PM72036 | SC453-002-15 | SCE905-001-01 A |

| SC722A-001-PM72012 | SC722A001 | SCE904AN-002-01 |

| SC722A-001-PM72005 | OS63D12 fuse switch | SCE952NN-504-01 |

| SC722A-001-PM72004 | SC453-004-05 | SCE952NN-501-01 |

| SC722A-001 | SC452-011-15 | SCE902AN-001-01 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218