GIDINGS&LEWIS H-4075-R-H00AA 伺服电机

1.产 品 资 料 介 绍:

Giddings & Lewis H-4075-R-H00AA 伺服电机产品特点

1. 高功率输出:从容应对高负载工业场景

2. 高速性能:满足精准高效的高速控制需求

3. 低惯性设计:显著提升动态响应灵敏度

英文资料:

Giddings&Lewis H-4075-R-H00AA servo motor product features

1. High power output: calmly cope with high load industrial scenarios

This servo motor has a rated power of 3.5 horsepower (approximately 2.6 kilowatts), with strong and stable power output capabilities, making it an ideal choice for high load industrial applications. In actual production, many heavy equipment need to operate under continuous high load conditions - for example, the spindle drive of heavy-duty CNC machine tools needs to drive large metal workpieces weighing hundreds of kilograms for cutting processing. The load torque is large and the processing cycle is long. The high-power output of the motor can ensure that the spindle always maintains a stable speed, avoiding a decrease in cutting efficiency, deviation in workpiece surface accuracy, or even scrap due to insufficient power; For example, in the field of port logistics, heavy-duty conveyor belt systems need to carry tens of kilograms of goods per box for continuous transportation. The motor can provide sufficient power to the conveyor belt, ensuring uninterrupted transportation and effectively improving logistics turnover efficiency. This high-power characteristic makes it widely adaptable to scenarios with strict power requirements, such as heavy machinery manufacturing, large-scale logistics transportation, and metallurgical equipment drive.

2. High speed performance: meets the precise and efficient high-speed control requirements

The maximum speed of the motor can reach 3000 revolutions per minute, and it can quickly respond to commands issued by the control system, perfectly adapting to high-speed positioning and dynamic control scenarios. In the field of automated production, high-speed operation and precise positioning are often the key to improving production efficiency. For example, in the electronics industry, high-speed surface mount machines need to accurately mount small-sized electronic components (such as chips and resistors) to designated positions on circuit boards in a short period of time. The high-speed performance of the motor can drive the mounting head to move at millisecond speed, and with the high-precision positioning system, it can achieve 3-5 mounting actions per second, greatly improving the production efficiency of circuit boards; For example, in the manufacturing of automotive parts, high-speed sorting equipment requires a high-speed conveyor belt to quickly sort different specifications of parts (such as bolts and washers) to the corresponding workstations. The high speed of the motor ensures that the conveyor belt maintains stable high-speed operation, avoiding sorting errors caused by speed fluctuations and improving sorting accuracy and overall production rhythm.

3. Low inertia design: significantly improves dynamic response sensitivity

Adopting a low inertia structure design significantly reduces the rotational inertia of the motor itself, thereby significantly improving the response speed of acceleration and deceleration, especially suitable for fast dynamic control scenarios that require frequent start stop and rapid speed changes. In the operation of industrial equipment, excessive inertia can easily lead to action delay or position overshoot, affecting control accuracy - for example, in the joint drive of automated robotic arms, the robotic arm needs to frequently switch action states during the process of grasping, moving, and placing workpieces. Low inertia motors can accelerate or decelerate the joints within 0.1 seconds, avoiding workpiece position deviation caused by inertia and ensuring the accuracy of grasping and placing; For example, the worktable drive of precision detection equipment requires the worktable to quickly move to the designated detection position and stop immediately. The low inertia design can ensure that the worktable starts and stops quickly, reduce detection waiting time, and improve detection efficiency,

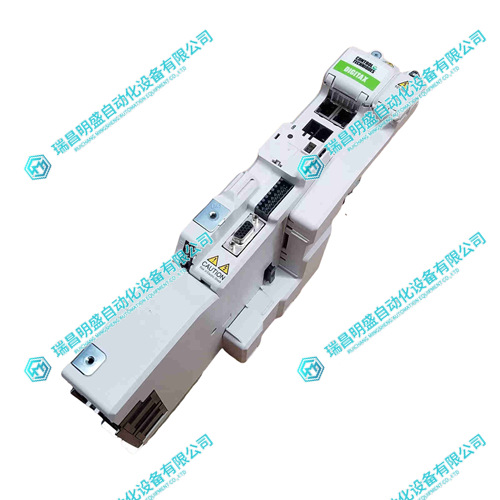

2.产 品 展 示

3.其他产品

4.其他英文产品

ABB SB822 3BSE018172R1 rechargeable

ABB UN0803B-P Printed Circuit Board

| PMB33F-00216-03 | CT 370a | R43HMAA-R2-NS-VS-00 |

| PMB33F-00216-02 | 70AA01a-E | R45GCNA-TS-NS-NV-00 |

| PMB33F-00216-01 | 70AA02B-E | P21NRXA-LNF-NS-00 |

| PMB33F-00216-00 | 70FV01B-E | P22NRXA-LSF-NS-02 |

| PMB33F-00214-03 | 70BK02B-E | M21NRXB-LDN-NS-00 |

| PMB33F-00214-02 | 70 WB 01a | P21NRXD-LNN-NS-00 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218