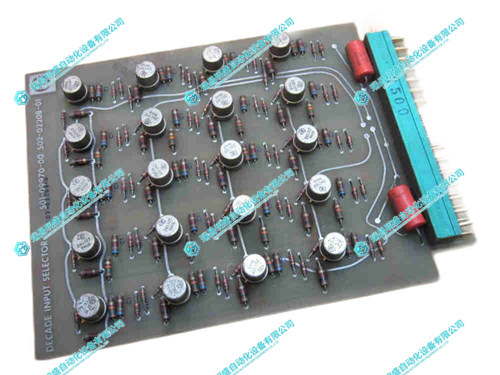

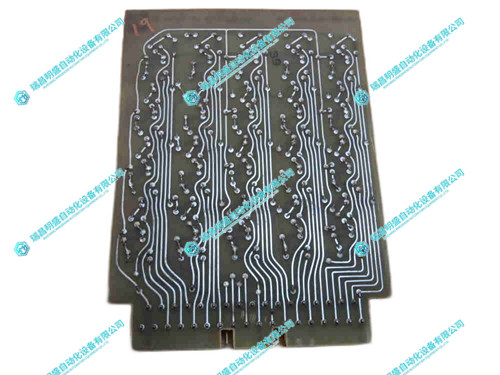

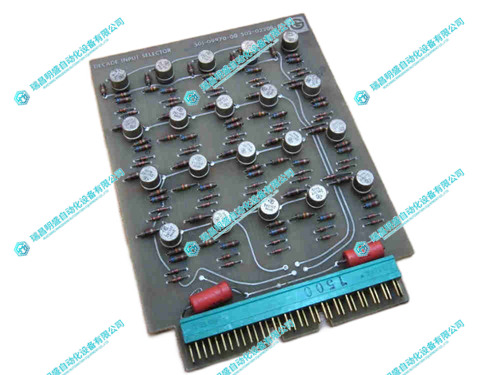

GIDINGS&LEWIS 502-02208-01输入模块

1.产 品 资 料 介 绍:

Giddings & Lewis 502-02208-01 输入选择模块(推测)产品特点

1. 输入信号选择功能:精准筛选关键控制信号

2. 模块化设计:灵活适配多场景系统搭建

3. 高可靠性:稳定应对复杂工业环境

英文资料:

Giddings&Lewis 502-02208-01 Input Selection Module (Speculative) Product Features

1. Input signal selection function: precise screening of key control signals

As the core function of the input selection module, this module can accurately switch and select between multiple input signal sources (such as sensors, detection devices, external controllers), ensuring that the control system can obtain the correct input signals according to production needs. In complex industrial scenarios, equipment often needs to receive multiple signals and prioritize responding to key signals - for example, in CNC machining, the system is simultaneously connected to multiple signals such as tool position sensors, workpiece temperature sensors, spindle speed sensors, etc. When the workpiece temperature rises abnormally during the machining process, the module can quickly switch to the temperature sensor signal, prioritize the transmission of temperature data to the controller, trigger the cooling system to start or pause processing, and avoid the workpiece being scrapped due to high temperature; For example, in the material detection process of an automated production line, the module can select the current required signal based on the production process from multiple signals such as "photoelectric sensor detects material arrival" and "weight sensor detects material qualification" to ensure the efficient operation of the production line in sequence. This signal selection capability allows the control system to focus on key information and improve response accuracy.

2. Modular design: flexible adaptation to multi scenario system construction

Adopting a standardized modular structure, it can be seamlessly combined with CPU modules, driver modules, output modules, and other components within the Giddings&Lewis product system, supporting flexible system configuration according to different industrial scenarios. In practical applications, enterprises can build differentiated control systems as needed - for example, when building a small automated assembly line, only one input selection module, along with one CPU module and one output module, is needed to achieve basic signal selection and control; When the production scale expands and the number of signal acquisition channels needs to be increased, there is no need to replace the module body. Only the same type of input selection module needs to be added and spliced with the original system through standard interfaces to expand the signal selection channels and meet the signal management needs of more devices. This design not only reduces the initial setup cost of the system, but also makes later upgrades more convenient, avoiding long downtime caused by system refactoring, and adapting to diverse needs from simple equipment control to complex production line management.

3. High reliability: Stable response to complex industrial environments

As the core component of the Giddings&Lewis control system, it is speculated that this module has undergone rigorous quality control and environmental testing, including high temperature (-40 ℃ to 70 ℃), high vibration (10-500Hz random vibration), electromagnetic compatibility (EMC) testing, etc., to ensure stable operation in complex industrial environments. In harsh scenarios such as metallurgy and chemical engineering, high temperatures, dust, and strong electromagnetic interference in the workshop can easily cause signal distortion or hardware failures in ordinary input modules - for example, in the steel rolling production line of a steel plant, the strong electromagnetic radiation generated by high-power motors during operation may interfere with the signal transmission of ordinary modules,

2.产 品 展 示

3.其他产品

4.其他英文产品

RADISYS 061-05927-0031 adapter module

KOLLMORGEN S70602-NANANA servo/driver

| PMB33F-00100-01 | NICL01 | P21NRXC-LSS-NS-06 |

| PMB33F-00100-00 | IMDSO04 | M22NRXA-JNN-NS-00 |

| PMB33E-20216-03 | 07EA80 | N31HLLL-LNK-NS-01 |

| PMB33E-20216-02 | IMAMM03 | M21NSXA-LNF-NS-02 |

| PMB33E-20216-01 | AMAT 0100-90941 | P22NRXB-LDF-NS-00 |

| PMB33E-20216-00 | 07BE62R1 | 5730030-UR DSAO 130 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218