GIDINGS&LEWIS 502-02181-00输入输出模块

1.产 品 资 料 介 绍:

Giddings & Lewis 502-02181-00 输入输出模块:产品定位与核心功能

核心应用领域解析

1. 数控机床(CNC):保障精密加工与稳定运行

2. 自动化生产线:实现生产过程实时管控

英文资料:

Giddings&Lewis 502-02181-00 Input/Output Module: Product Positioning and Core Functions

As the exclusive relay driver board for the Giddings&Lewis PiC900 control system, the core value of the 502-02181-00 input-output module lies in signal interaction and control execution in industrial automation scenarios. On the one hand, it can accurately collect input signals from industrial equipment (such as sensor feedback position, temperature, pressure signals), and on the other hand, it can output control signals according to controller instructions to drive actuators (such as motors, solenoid valves, indicator lights) to act. It is a key bridge connecting the "perception layer" and the "execution layer". In practical applications, this module needs to work in conjunction with other components of the PiC900 system (such as CPU modules, driver modules, and other I/O expansion modules) - for example, through the control logic received by the CPU module, this module can collect signals from machine tool sensors, and then output signals to control the tool magazine motor to switch tools, ultimately building a complete and efficient automation control loop that adapts to diverse control requirements from standard equipment to customized systems.

Analysis of core application areas

1. Numerical Control Machine Tool (CNC): Ensuring Precision Machining and Stable Operation

In CNC machine tools such as milling machines, lathes, and grinders, the 502-02181-00 input/output module is the core component for achieving "precise perception precise control". During the machining process of machine tools, it is necessary to simultaneously process the signal interaction between multiple sensors and actuators: through the input channel, the module can collect real-time signals from tool position sensors (feedback on whether the tool is in place), workpiece clamping sensors (confirm whether the workpiece is firmly clamped), spindle temperature sensors (monitor spindle operating temperature), etc., to ensure that the controller timely grasps the equipment operating status; Through the output channel, the module can drive actuators such as the tool magazine motor (controlling tool switching), cooling system solenoid valve (adjusting coolant switch), spindle start stop relay (controlling spindle operation), etc. For example, in precision milling, when the module collects sensor signals indicating "excessive tool wear", it immediately transmits the signal to the PiC900 controller. After the controller issues an instruction, the module outputs a signal to drive the tool magazine motor to replace the spare tool. The entire process does not require manual intervention, ensuring machining accuracy (avoiding workpiece size deviation caused by tool wear) and maintaining continuous and stable operation of the machine tool, reducing machining interruption time.

2. Automated production line: achieving real-time control of the production process

In automated production lines such as automotive parts assembly and electronic component processing, this module achieves real-time monitoring and precise control of the entire production process through the process of "signal acquisition logic judgment execution control". In the production line, the input channel of the module can be connected to devices such as photoelectric sensors (to detect whether the material is in place), pressure sensors (to monitor whether the assembly pressure meets the standard), counters (to count the output), etc., to obtain real-time production data;

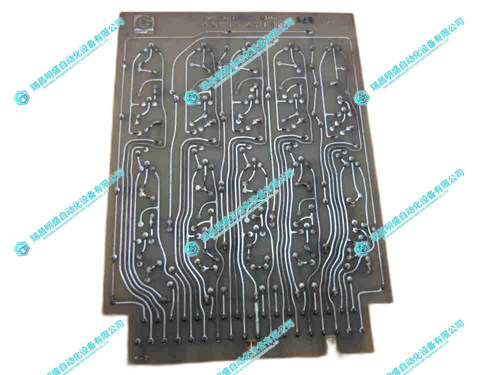

2.产 品 展 示

3.其他产品

4.其他英文产品

KOLLMORGEN S70602-NANANA servo/driver

ASEA ES1530b module card board

3BHE009681R0101 GVC750BE101 thyristor hi

| PMB33E-20201-01 | 70 BL 30a | 57120001-MZ DSTA 191 |

| PMB33E-20201-00 | NTAI02 | PFTL301E 0.5KN 3BSE019050R500 |

| PMB33E-20200-03 | 07PS63R3 | M21NRXC-JNN-NS-00 |

| PMB33E-20200-02 | 6240BP10411A | P22NRXD-LSN-NS-03 |

| PMB33E-20200-01 | AMAT 130-0303 | PWM5330-5711-45B |

| PMB33E-20200-00 | 70 PR 02a-E | P21NSHS-LNS-NS-02 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218