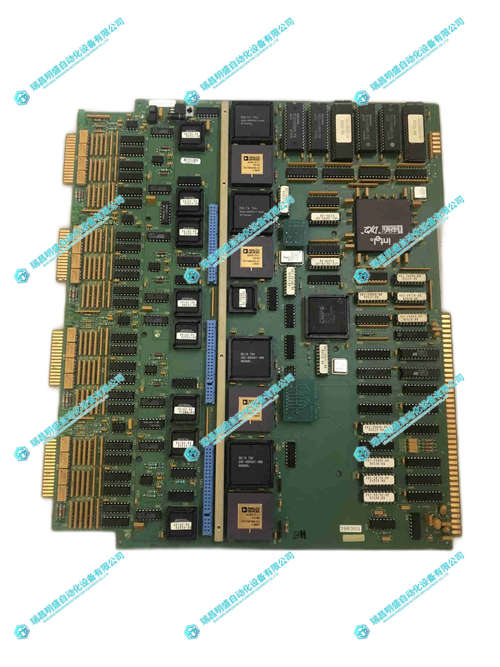

GIDINGS&LEWIS 502-03927-01 通信模块

1.产 品 资 料 介 绍:

产品特点(推测)

1. 多协议通信支持

2. 高速数据传输

3. 强抗干扰设计

4. 模块化集成

5. 广泛兼容性

6. 诊断与冗余功能

应用领域(推测)

1. 数控机床(CNC)

2. 自动化生产线

3. 机器人控制系统

4. 包装与检测设备

5. 定制自动化设备

英文资料:

Product Features (Speculation)

1. Multi protocol communication support

It is speculated that supporting mainstream industrial communication protocols such as Ethernet, RS-485, DeviceNet, etc., can achieve efficient data exchange between controllers and I/O modules, drivers, upper computers, and other devices, and adapt to different system communication requirements.

2. High speed data transmission

Equipped with high-speed signal transmission capability, the data transmission rate meets the requirements of real-time control scenarios, avoiding system response lag caused by communication delays, and ensuring smooth automation processes.

3. Strong anti-interference design

Adopting industrial grade anti electromagnetic interference technology, it can resist electromagnetic interference generated by equipment such as motors and frequency converters in the workshop, ensure stable communication signals in complex industrial environments, and reduce data packet loss.

4. Modular integration

Continuing the modular design, it can seamlessly integrate with the CPU, I/O modules, and other components of the Giddings&Lewis PiC900 control system, supporting flexible system expansion and simplifying installation and maintenance.

5. Wide compatibility

It is speculated that it is compatible with multiple series of control systems under Giddings&Lewis, and can also adapt to third-party industrial equipment such as sensors and human-machine interfaces, reducing the difficulty of cross brand system integration.

6. Diagnostic and redundant functions

Possible built-in communication status monitoring and fault alarm functions, facilitating quick troubleshooting of communication anomalies; Partial scenarios support redundant communication design to enhance system communication reliability and avoid downtime caused by single point failures.

Application field (speculated)

1. Numerical Control Machine Tool (CNC)

Realize data exchange between machine tool controller, tool magazine, spindle driver, and detection module, ensure real-time transmission of machining parameters, and improve machine tool machining accuracy and operational stability.

2. Automated production line

Connect the controllers of each workstation on the production line with the central monitoring system, upload real-time production data (such as output and equipment status), issue scheduling instructions, optimize production rhythm, and improve efficiency.

3. Robot control system

Establish communication links between industrial robots, upper computers, and peripheral devices (such as conveyors and fixtures) to ensure real-time synchronization of robot motion commands and position feedback, ensuring operational accuracy.

4. Packaging and testing equipment

Realize signal transmission between equipment control system, detection sensors, and packaging actuators, ensure real-time interaction of packaging parameters and detection data, and improve equipment automation level and product qualification rate.

5. Customized automation equipment

Adapt to the complex communication requirements of customized systems, connect various non-standard devices and control centers, and meet the data transmission and collaborative control requirements in special industrial scenarios.

2.产 品 展 示

3.其他产品

ABSOLUTE PROCESS API4380GD隔离变送器

4.其他英文产品

AMAT 0190-11415 Digital Input Module

ABB XVC768117 Field Input/Output Module

| PMB33E-10200-00 | INNPM11 | 3BSE019300R1 DSRF 200 |

| PMB33E-10116-03 | IMCIS22 | 57160001-KG DSDP 160 |

| PMB33E-10116-02 | IMCOM03 | PFTL201CE 50.0KN 3BSE007913R51 |

| PMB33E-10116-01 | NTDO02 | 57160001-DF DSDI 301 |

| PMB33E-10116-00 | 70 FK01a | P21NSXC-LSS-NS-07 |

| PMB33E-10114-03 | NKTM010 | PMB33F-20114-03 |

| PMB33E-10114-02 | AMAT 0160-00018 | 57120001-NT DSAI 130H |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218