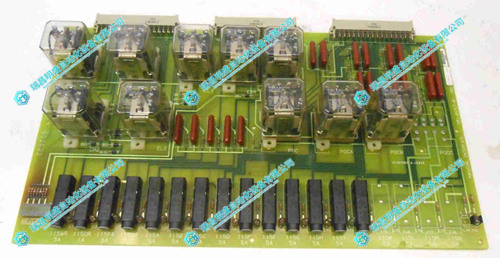

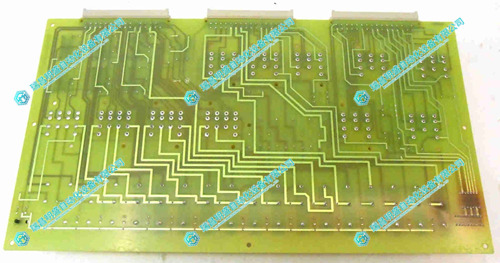

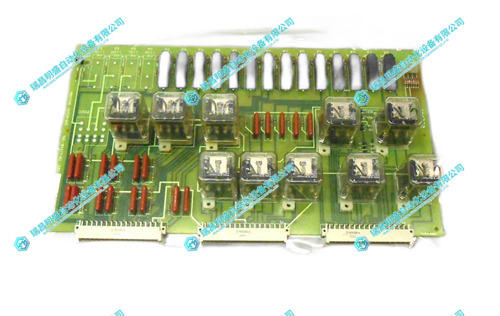

GIDINGS&LEWIS 502-03431-10S机器接口板

1.产 品 资 料 介 绍:

产品定位

产品特点(推测)

1. 信号接口功能

2. 模块化设计

3. 高可靠性

4. 兼容性强

5. 实时控制能力

6. 多通信接口

7. 诊断功能

8. 扩展性

典型应用领域(推测)

1. 数控机床

2. 自动化生产线

3. 机器人控制系统

4. 定制自动化设备

英文资料:

Product positioning

502-03431-10S is a key machine interface board for the Giddings&Lewis PiC900 control system. Its core function is to build a signal bridge between the control system and machine tools/automation equipment, enabling the transmission and conversion of input and output signals. It needs to work in conjunction with I/O modules, drivers, and controllers to construct a complete automation control loop.

Product Features (Speculation)

1. Signal interface function

The signal line connecting the control system and equipment, completing the transmission and conversion of input and output signals, ensuring smooth signal interaction between the two, is a key connecting component between the "control center" and the "equipment terminal".

2. Modular design

Adopting a modular structure, it can be flexibly combined with the CPU, driver, and I/O modules of the PiC900 system, supporting on-demand configuration and expansion of the system, reducing the difficulty of building and upgrading.

3. High reliability

It is speculated that through strict quality control, it has industrial grade anti-interference, anti temperature change, and anti vibration capabilities, and can operate stably in complex industrial environments, reducing downtime caused by faults.

4. Strong compatibility

Highly compatible with other modules of the PiC900 control system, and adaptable to various industrial automation application scenarios, it can be integrated without significant modifications.

5. Real time control capability

May have real-time data processing capabilities, suitable for scenarios with high real-time requirements such as CNC machine tools and automated production lines, ensuring signal transmission and control without delay.

6. Multiple communication interfaces

It is speculated that it supports interfaces such as RS-232, RS-485, Ethernet, etc., which facilitates data exchange with other devices and improves the flexibility of system interconnection.

7. Diagnostic function

It may have built-in status monitoring and fault alarms, which can provide feedback on abnormal information and provide troubleshooting guidance, reducing maintenance difficulty and time costs.

8. Scalability

Support connection with other modules, expandable input and output points, number of drive axes, etc., to meet the needs of system function upgrades.

Typical application areas (speculated)

1. CNC machine tools

Realize signal interaction between the PiC900 control system and the machine tool, transmit machining parameters and equipment status signals, and ensure precise machining and stable operation of the machine tool.

2. Automated production line

Connect the production line control system with various equipment, transmit production instructions and operational data in real-time, and improve production efficiency and quality stability.

3. Robot control system

Build an interface between the robot and the control system, transmit motion control commands and position feedback signals to ensure precise and safe operation of the robot.

4. Customized automation equipment

Adapt to the signal interaction requirements of non-standard automation equipment, achieve the connection between control systems and equipment according to specific scenarios, and meet personalized control requirements.

2.产 品 展 示

3.其他产品

ABSOLUTE PROCESS API4380GD隔离变送器

4.其他英文产品

ASEA SNAT7600 driver control circuit board

ABB 3DDE300417 Input/Output Board

| PMB33E-10100-03 | IEPAS02 | PFTL301E 1.0KN 3BSE019050R1000 |

| PMB33E-10100-02 | 07PS62R3 | 3BSE011181R1 PM511V16 |

| PMB33E-10100-01 | NIMF01 | PMB33F-20114-00 |

| PMB33E-10100-00 | BC1011 | 57160001-GF DSDP 150 |

| PMB33E-00216-03 | 70 SK 34b-E | 57120001-PX DSTA 001 |

| PMB33E-00216-02 | IMFBS01 | M21NSXA-LNN-NS-02 |

| PMB33E-00216-01 | IEMMU01 | P2HNRH-LNN-NS-00 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218