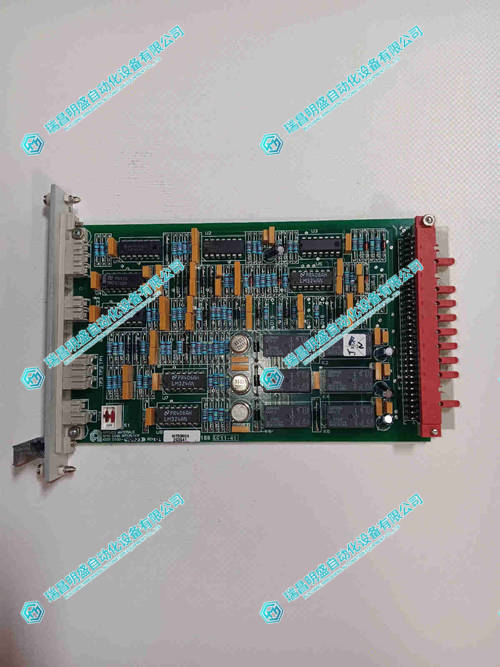

GIDINGS&LEWIS M.1016.9719扫描仪模块

1.产 品 资 料 介 绍:

产品概述

技术参数(典型特性,具体以实际型号为准)

英文资料:

Product Overview

In the field of precision control in industrial automation, the GIDINGS&LEWIS M.1016.9719 scanner module occupies a pivotal position and is a professional industrial grade position and speed detection equipment. Its core function focuses on precise motion control of CNC machine tools and automation systems, providing crucial feedback information to the system by collecting real-time position signals during mechanical motion. In complex industrial operating environments, it relies on a closed-loop feedback mechanism to convert high-precision position data collected into precise control inputs, ensuring accurate positioning of the machining process or equipment movement. Whether it is millimeter or micrometer level positioning requirements, it can achieve precise positioning. In a multi axis linkage automation system, this module can achieve high synchronization of the movements of each axis, making the entire industrial production process smoother and more efficient, greatly improving production quality and efficiency.

Technical parameters (typical characteristics, specific subject to actual model)

Measurement type: With strong adaptability, it can flexibly handle rotating or linear position scanning tasks. In the spindle rotation monitoring scenario of CNC machine tools, each rotation of the spindle can be accurately captured, and the rotation angle information can be fed back to the control system in real time to assist in adjusting cutting parameters and ensuring machining accuracy. In the linear guide motion monitoring of automated production lines, accurate measurement of linear displacement can be carried out, providing reliable data support for the precise positioning of equipment and meeting the diverse detection needs of different industrial equipment in motion forms.

Feedback accuracy: Adopting high-resolution encoder feedback technology is the key to achieving high-precision detection. Its high resolution can ensure reaching micrometer level or even higher precision standards. Taking the CNC machine tool for precision mold processing as an example, when performing fine milling on molds, the M.1016.9719 scanner module can accurately feedback the position accuracy of the tool to the micrometer level, allowing the control system to fine tune the tool path in real time based on the feedback information, ensuring that the processed mold surface is smooth and the size is accurate, greatly meeting the strict requirements of high-end manufacturing industry for machining accuracy.

Response speed: With high-speed signal acquisition capability, it can perfectly adapt to fast motion control scenarios. In automated production lines, when material handling robots need to complete fast grasping and handling actions in a short period of time, the scanner module can quickly collect the position signals of each joint of the robot and transmit them to the control system quickly. The control system adjusts the motion parameters of the robot in a timely manner based on these real-time signals, ensuring the accuracy and smoothness of the robot's actions, avoiding action errors or collision accidents caused by signal acquisition and transmission delays, and effectively improving production efficiency.

Interface method: Adopting standard industrial interface design, this design makes it widely compatible. Whether connected to a CNC controller or working in conjunction with a servo system, seamless integration can be achieved.

2.产 品 展 示

3.其他产品

4.其他英文产品

TOYOTA PRS-2796B Circuit Board

TOYOTA TP-7217-4 Interface Card

TOYOTA TP-8901-1 Circuit Board

| PMA22S-01100-00 | AMAT 0100-35069 | PFRL101C |

| PMA22B-10114-01 | AMAT 0100-35213 | PFEA112 |

| PMA22B-10100-00 | AMAT 0100-14003 | PFTL101A-0.5 3BSE004160R1 0.5 |

| PMA22B-01100-22 | AMAT 0100-35279 | PFTL101A-1.0KN 3BSE004166R1 |

| PMA22B-01100-00 | AMAT 0100-77043 | PFTL 101AER-1.0KN |

| PMA22B-00100-00 | AMAT 0100-00060 | PFTL-101A 3BSE008508R1 |

| PMA21B-10100-00 | AMAT 0100-00059 | PFEA112-65 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218