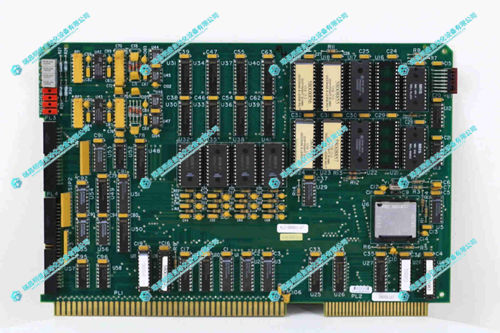

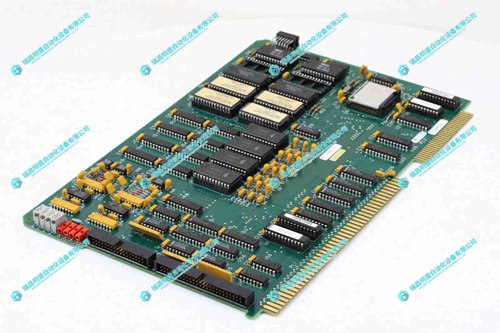

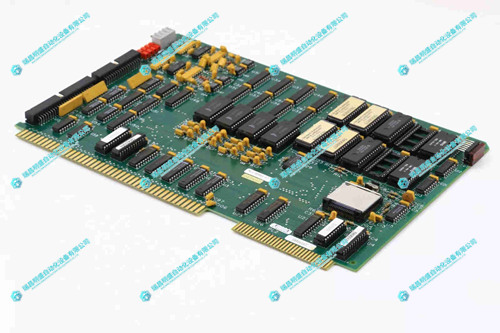

GIDINGS&LEWIS 411-80061-67控制器模块

1.产 品 资 料 介 绍:

GIDDINGS & LEWIS 411 - 80061 - 67 控制器模块介绍

产品概述

产品特点

英文资料:

Introduction to GIDINGS&LEWIS 411-80061-67 Controller Module

Product Overview

In the construction of CNC machine tools and industrial automation systems, the GIDINGS&LEWIS 411-80061-67 controller module plays a key role as the core brain. Its workflow is closely centered around industrial production needs, and it can keenly capture input signals from various sensors, operation panels, etc. These signals contain rich information such as equipment operating status, external environmental changes, and operator instructions. The module is equipped with precision computing logic units, which quickly perform deep analysis and logical operations on input signals. Based on preset programs and algorithms, it accurately generates control instructions and outputs them to drivers, actuators, or peripheral devices in a timely manner. Whether it is precise planning of tool paths during CNC machining or orderly scheduling of collaborative operations among various equipment in automated production lines, precise command from this module is indispensable. In terms of design concept, it is built to industrial standards, with excellent high reliability, and can cope with complex and changing working conditions in industrial sites; Having powerful high-performance processing capabilities, easily handling massive data operations and complex tasks; The unique anti-interference design enables it to operate stably in harsh environments such as strong electromagnetic and vibration, providing a solid guarantee for the long-term stable and efficient operation of the entire industrial system.

Product Features

High speed processing capability: To meet the ultimate pursuit of data processing speed and multitasking in the industrial control field, the 411-80061-67 controller module is equipped with advanced industrial grade processors. When performing complex surface machining on CNC machine tools, it is necessary to plan the complex path of the tool in three-dimensional space in real time, while coordinating the synchronous motion of multi axis motors. With powerful computing capabilities, this processor quickly calculates key data such as the position, velocity, and acceleration of each axis, ensuring that the tool moves accurately along the complex trajectory and achieves micrometer level machining accuracy. In automated production lines, multiple tasks such as material handling, equipment start stop, and quality inspection are involved simultaneously. It can process a large number of signals from different links in parallel, quickly issue control instructions, ensure efficient and stable operation of the production line, greatly improve industrial production efficiency, and meet the strict requirements of modern manufacturing for high-precision and high-speed processing.

High reliability: The industrial environment is full of challenges, and harsh conditions such as vibration and high temperature constantly test the stability of equipment. The 411-80061-67 controller module fully considers these factors in its design, using anti vibration materials and structural design to effectively absorb and disperse external vibration energy, ensuring stable operation of internal electronic components in a vibration environment, and avoiding faults such as poor contact and loose solder joints caused by vibration. In terms of high temperature resistance, high-temperature electronic components are selected and the heat dissipation structure is optimized. Even in high-temperature production sites such as metallurgy and casting, where temperatures can reach tens of degrees Celsius, the module can operate stably without performance degradation or failure due to overheating.

2.产 品 展 示

3.其他产品

4.其他英文产品

Gasonics A90-027-01 Power Controller

Gasonics RD-323M10 Stepper Driver

5SHY4045L0006 3BHB030310R0001 thyristor

| PC834-001-T | AMAT 0100-90468 | HESG447224R0002 70AB01C-ES |

| PC834-001-N | AMAT 0100-00329 | PHARPS32000000 |

| PC834-001-A | AMAT 0190-35217 | NKAS01-15 |

| PC834-001 | AMAT 0100-20453 | 57120001-FG DSAO 30 ABB |

| PC833-XYZ-T | AMAT 0100-18065 | NKEB01 |

| PC833-XYZ-N | AMAT 0090-01270 | HESG447440R0001 RS232 |

| PC833-XYZ-A | AMAT 0100-90269 | 57520001-BC DSCS116 ABB |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218